From a technical standpoint, the primary advantage of vacuum heat treatment for surface quality is its ability to completely prevent surface reactions like oxidation and decarburization. By processing parts in a near-total vacuum, the material never comes into contact with atmospheric oxygen or other reactive gases. This ensures components emerge from the furnace with a bright, clean, and unaltered surface, often eliminating the need for costly and time-consuming post-treatment cleaning or machining.

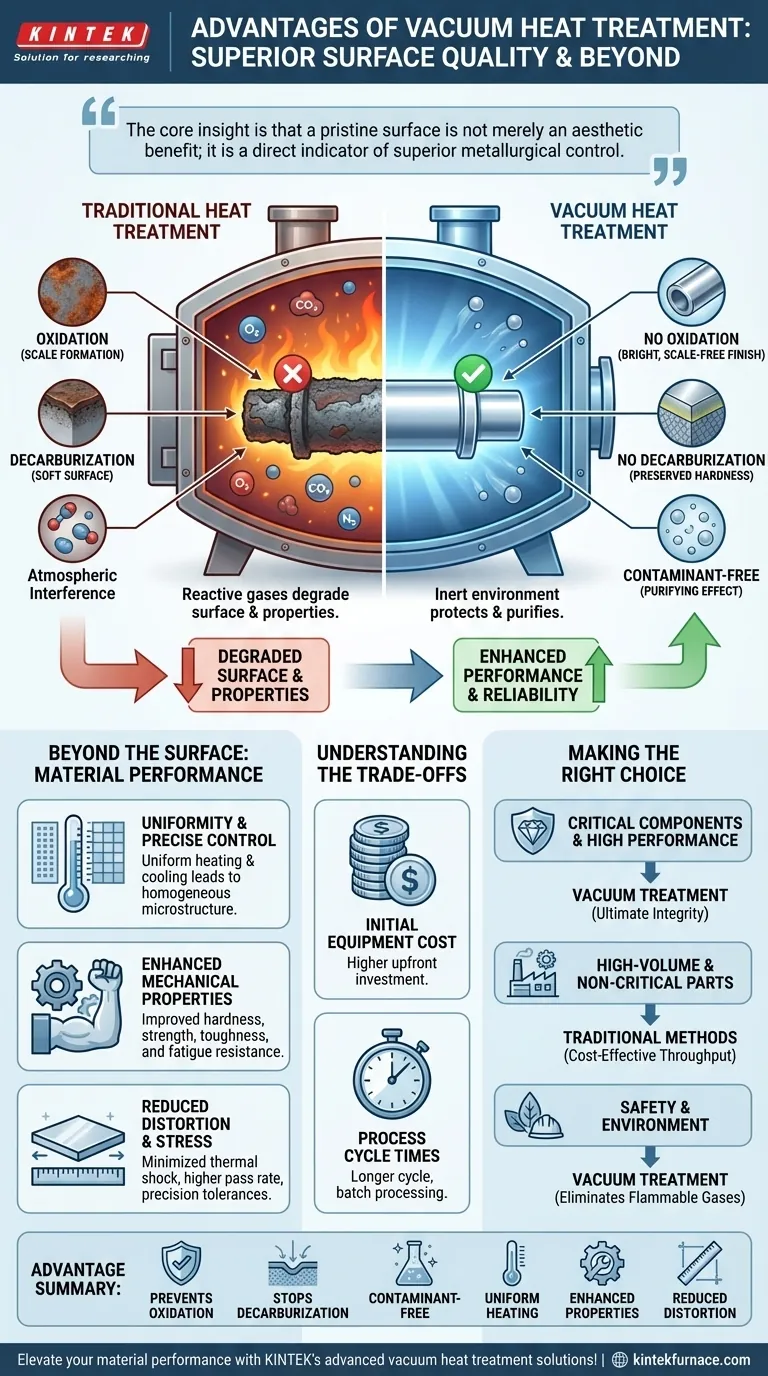

The core insight is that a pristine surface is not merely an aesthetic benefit; it is a direct indicator of superior metallurgical control. By eliminating all atmospheric interference, vacuum treatment ensures the material's intended properties are fully realized and even enhanced, rather than being compromised from the outside in.

The Fundamental Advantage: Eliminating Atmospheric Interference

The defining characteristic of vacuum heat treatment is the removal of the atmosphere, which is the root cause of surface degradation in many traditional methods. This creates an exceptionally pure processing environment.

Preventing Oxidation

In traditional furnaces, ambient oxygen reacts with the hot metal surface, forming a layer of oxide scale. This scale degrades the finish, reduces dimensional accuracy, and can even lead to performance issues like quenching soft spots or cracking.

Vacuum heat treatment physically removes the oxygen, preventing this reaction entirely. The result is a bright, scale-free surface that maintains its original metallic luster and precision.

Stopping Decarburization

Decarburization is the loss of carbon from the surface layer of steel alloys at high temperatures. This process softens the surface, reducing its wear resistance and fatigue life, which is a critical failure point for many components.

The vacuum environment is inert, meaning there are no molecules present to react with and draw out the carbon from the steel. This preserves the engineered hardness and performance characteristics of the material's surface.

Achieving a Contaminant-Free Finish

Beyond just oxygen, the vacuum removes other potential contaminants. The process also has a purifying effect, pulling out trapped gases like hydrogen from the material itself, which helps prevent issues like hydrogen embrittlement.

This eliminates the need for protective gas atmospheres (like hydrogen or argon), which can be expensive, flammable, and introduce their own contamination risks. The part emerges clean, degassed, and ready for use.

Beyond the Surface: Impact on Material Performance

The control offered by a vacuum environment extends deep into the material, yielding significant improvements in mechanical properties and part reliability.

Uniformity and Precise Control

Vacuum furnaces allow for extremely precise temperature control and uniform heating. With no atmosphere to circulate, heat is transferred primarily through radiation, which is highly consistent.

This uniform heating and controlled cooling result in a more homogenous microstructure throughout the component, leading to predictable and repeatable material properties.

Enhanced Mechanical Properties

By preventing surface degradation and ensuring a uniform internal structure, vacuum treatment allows materials to achieve their full potential.

This regularly leads to measurable improvements in hardness, strength, toughness, and fatigue resistance. The process enhances the material's inherent properties rather than just protecting them.

Reduced Distortion and Thermal Stress

The highly controlled cooling cycles possible in a vacuum furnace minimize the thermal shock that causes parts to warp or crack. This is critical for complex geometries or high-precision components.

The result is a higher pass rate, with less material lost to distortion, and a final product that holds its intended shape and tolerances.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the universal solution. Acknowledging its specific trade-offs is key to making an informed decision.

Initial Equipment Cost

Vacuum furnaces are complex systems that represent a significant capital investment compared to many conventional atmosphere furnaces. The upfront cost can be a major consideration.

Process Cycle Times

While thermal efficiency is high, the overall cycle time can be longer. Time is required to pump the chamber down to the required vacuum level before the heating cycle can even begin. For very high-volume, continuous production, this batch-style processing can be a bottleneck.

Suitability and Application

The benefits of vacuum treatment are most pronounced on high-value materials and components where performance, purity, and surface integrity are non-negotiable. For low-cost, bulk-treated parts where a simple oxide scale is acceptable or easily removed, a less expensive traditional method may be more economical.

Making the Right Choice for Your Application

Choosing between vacuum and traditional heat treatment depends entirely on your project's specific priorities and the value of the component being treated.

- If your primary focus is ultimate surface integrity and material performance: Vacuum treatment is the definitive choice, as it eliminates surface degradation and provides unparalleled process control for critical components.

- If your primary focus is high-volume production of non-critical parts: Traditional atmosphere-controlled furnaces may offer a more cost-effective throughput, provided some post-treatment finishing is acceptable.

- If your primary focus is operational safety and environmental impact: Vacuum heat treatment offers a clear advantage by eliminating flammable process gases and pollutants.

Ultimately, understanding these core principles empowers you to select the process that best protects and enhances the value of your components.

Summary Table:

| Advantage | Description |

|---|---|

| Prevents Oxidation | Eliminates surface scale by removing oxygen, ensuring bright, clean finishes. |

| Stops Decarburization | Preserves carbon content for maintained hardness and wear resistance. |

| Contaminant-Free Finish | Removes gases like hydrogen, reducing embrittlement and contamination risks. |

| Uniform Heating | Uses radiation for precise temperature control and homogeneous microstructure. |

| Enhanced Mechanical Properties | Improves hardness, strength, toughness, and fatigue resistance. |

| Reduced Distortion | Minimizes warping and cracking with controlled cooling cycles. |

Elevate your material performance with KINTEK's advanced vacuum heat treatment solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering superior surface quality and enhanced durability for critical components. Contact us today to discuss how our tailored solutions can optimize your heat treatment processes and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control