In vacuum sintering, reducing contamination is the single most critical factor for achieving a high-quality final product. By removing reactive gases from the furnace environment, you prevent unwanted chemical reactions that introduce defects, weaken the material, and ultimately compromise the structural integrity of the sintered part.

The core purpose of using a vacuum is to create an inert environment. This ensures that the only bonds formed during heating are between the metal particles themselves, allowing the part to achieve its maximum theoretical density, strength, and purity.

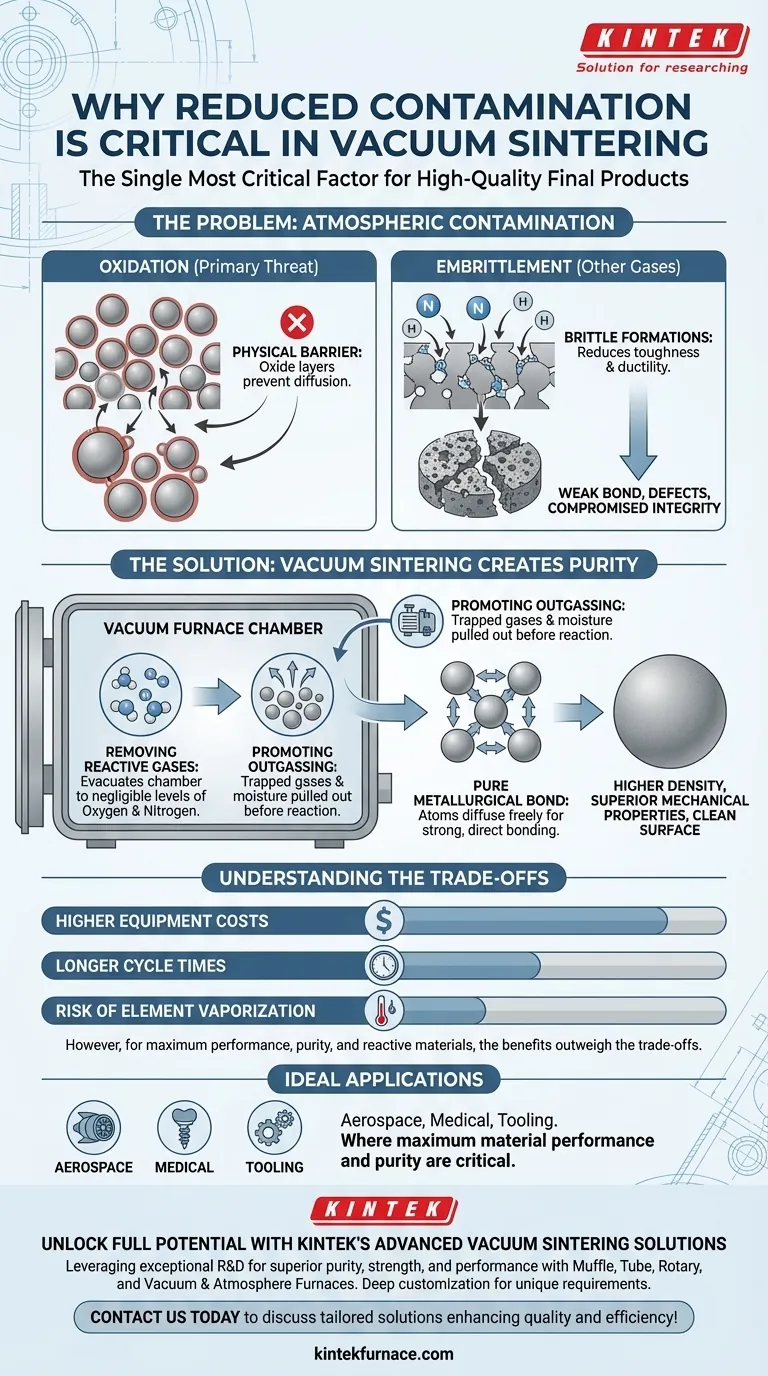

The Problem with Atmosphere

Sintering relies on heating metal powders to just below their melting point, causing the particles to fuse together. The presence of any atmospheric gas, even in trace amounts, can disrupt this delicate process.

Oxidation: The Primary Threat

Most metals, especially when heated, have a strong affinity for oxygen. Even a small amount of oxygen in the furnace will form a thin, hard layer of oxide on the surface of each powder particle.

These oxide layers act as a physical barrier. They prevent the metal-to-metal diffusion and bonding that is essential for densification, leaving behind microscopic voids and weak points in the final structure.

Embrittlement from Other Gases

Oxygen isn't the only concern. Gases like nitrogen and hydrogen can also be absorbed by the metal at high temperatures.

This absorption can lead to the formation of nitrides or hydrides within the metal's crystal structure. These formations make the final material brittle, severely reducing its toughness and ductility.

How Vacuum Sintering Creates Purity

A vacuum furnace directly solves the problem of atmospheric contamination by physically removing the air and other vapors before the heating cycle begins.

Removing Reactive Gases

The primary function of the vacuum pump is to evacuate the furnace chamber, lowering the pressure to a point where the concentration of reactive gases like oxygen and nitrogen is negligible. This starves potential chemical reactions of their fuel.

Promoting Outgassing

A key benefit of the vacuum environment is its ability to promote outgassing. As the pressure drops, any gases or moisture trapped within the powder mass or adsorbed onto the particle surfaces are pulled out of the material before they have a chance to react during heating.

The Result: A Pure Metallurgical Bond

With no interfering elements, the atoms at the surface of each powder particle are free to diffuse and form strong, direct metallurgical bonds with their neighbors. This results in a final part with higher density, superior mechanical properties like strength and wear resistance, and a clean, bright surface finish.

Understanding the Trade-offs

While vacuum sintering provides superior quality, it's essential to recognize the associated trade-offs compared to atmospheric sintering methods.

Higher Equipment Costs

Vacuum furnaces are more complex and expensive to build and maintain than their atmospheric counterparts. The need for robust chambers, high-performance pumps, and sophisticated controls adds to the initial investment.

Longer Cycle Times

Achieving a deep vacuum requires time to pump down the chamber. The entire process, including controlled heating and cooling cycles within the vacuum, can often be slower than sintering in a continuous belt furnace.

Risk of Element Vaporization

Under very high vacuum and temperature, some alloying elements with a high vapor pressure (like manganese, chromium, or zinc) can "boil off" or vaporize from the surface of the parts. This phenomenon, known as sublimation, can alter the final chemistry and properties of the material if not properly controlled.

Making the Right Choice for Your Goal

The decision to use vacuum sintering depends entirely on the requirements of the final application.

- If your primary focus is maximum material performance: For demanding applications in aerospace, medical, or tooling that require the highest possible strength and reliability, the purity achieved by vacuum sintering is essential.

- If your primary focus is processing reactive materials: For metals like titanium, refractory metals (tungsten, molybdenum), or certain stainless steels that oxidize readily, a vacuum environment is not just beneficial—it is a requirement.

- If your primary focus is cost-sensitive production: For less critical components where some porosity is acceptable and mechanical properties are not paramount, a more economical atmospheric sintering process may be sufficient.

Ultimately, controlling the furnace atmosphere is about controlling the final properties and performance of the material.

Summary Table:

| Aspect | Key Points |

|---|---|

| Problem with Atmosphere | Oxidation and embrittlement from gases like oxygen and nitrogen can cause defects and weaken materials. |

| Benefits of Vacuum Sintering | Removes reactive gases, promotes outgassing, and enables pure metallurgical bonds for higher density and strength. |

| Trade-offs | Higher equipment costs, longer cycle times, and risk of element vaporization must be considered. |

| Ideal Applications | Aerospace, medical, and tooling industries where maximum material performance and purity are critical. |

Unlock the Full Potential of Your Materials with KINTEK's Advanced Vacuum Sintering Solutions

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to deliver superior purity, strength, and performance for your sintering needs. With strong deep customization capabilities, we precisely meet your unique experimental requirements, ensuring optimal results in demanding applications like aerospace and medical industries.

Contact us today to discuss how our tailored vacuum sintering furnaces can enhance your material quality and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density