A high-vacuum system is fundamental to Physical Vapor Deposition (PVD) because it creates a pristine environment that governs both the physical trajectory and chemical composition of the coating. Specifically, it eliminates air resistance to allow precise ion transport and prevents environmental contaminants from degrading the hydroxyapatite structure.

The high-vacuum environment serves a dual purpose: it maximizes the unhindered travel of atoms to ensure doping elements integrate uniformly into the lattice, and it eliminates oxygen to guarantee the chemical purity essential for biomedical applications.

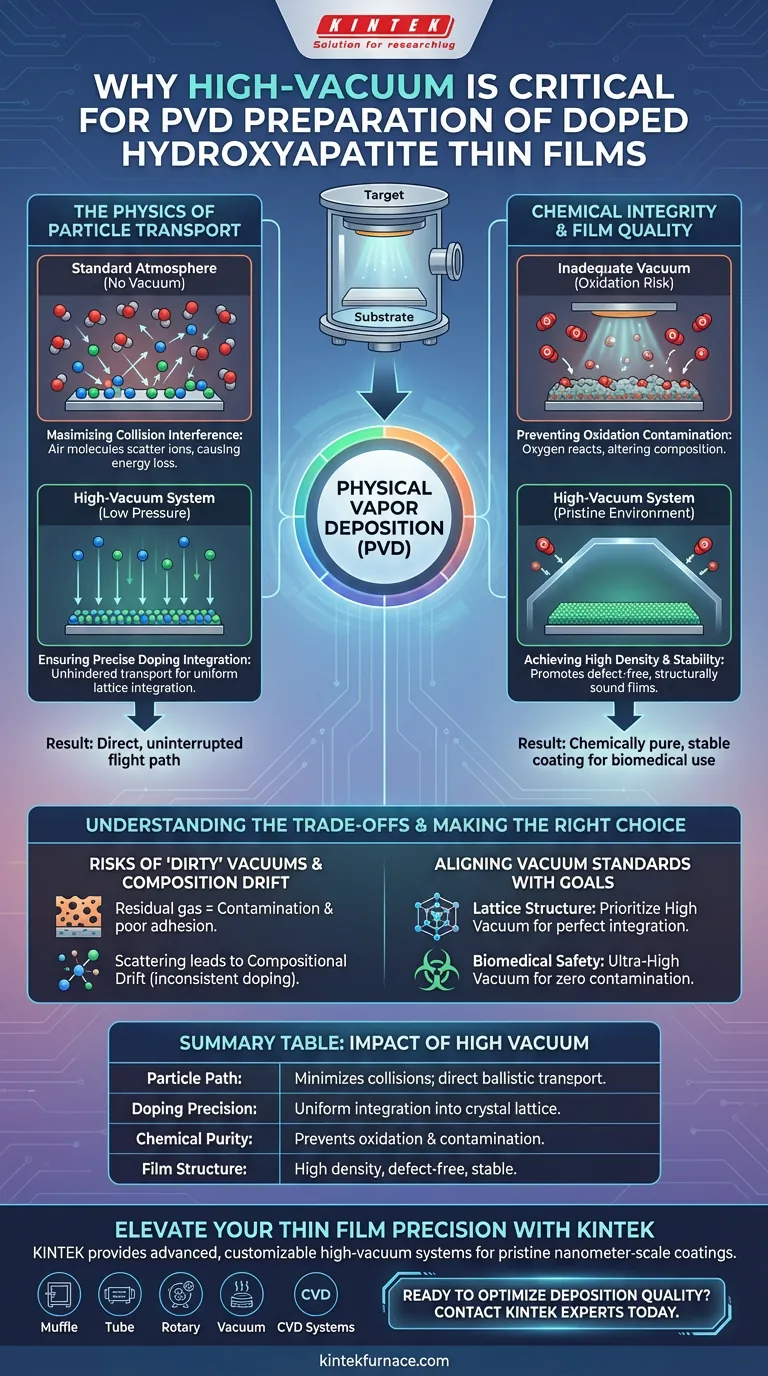

The Physics of Particle Transport

Minimizing Collision Interference

In a standard atmosphere, the air is crowded with gas molecules. A high-vacuum system removes these obstacles, creating a low-pressure environment.

This reduction in pressure minimizes collision interference between residual air molecules and the deposited ions. Without this vacuum, the coating material would scatter and lose energy before reaching the substrate.

Ensuring Precise Doping Integration

For doped hydroxyapatite, the goal is to insert specific elements into the film's crystal lattice. The vacuum ensures the "flight path" of these doping atoms is direct and uninterrupted.

This ballistic transport allows the doping elements to be precisely and uniformly integrated into the thin film lattice, rather than clustering randomly or failing to adhere.

Chemical Integrity and Film Quality

Preventing Oxidation Contamination

Hydroxyapatite is frequently used in biomedical settings, where chemical purity is non-negotiable. A high-vacuum environment creates a barrier against environmental reactions.

It specifically prevents oxidation contamination during the film formation process. Without a vacuum, oxygen in the chamber would react with the vaporized material, altering the chemical composition of the final coating.

Achieving High Density and Stability

A vacuum ensures that the sputtered atomic flux deposits directly onto the substrate without interference.

This direct deposition promotes the growth of highly dense, defect-free films. It ensures the resulting nanometer-scale electrolyte is structurally sound and compositionally precise.

Understanding the Trade-offs

The Risk of "Dirty" Vacuums

If the vacuum pressure is not sufficiently low, residual gas molecules remain in the chamber.

These molecules act as contaminants, leading to porous films with poor adhesion. The result is a coating that may look correct visually but lacks the structural integrity required for actual use.

Compositional Drift

Inadequate vacuum levels cause scattering, which affects light atoms and heavy atoms differently.

This leads to compositional drift, where the stoichiometry of the deposited film no longer matches the target material. For doped films, this means the doping concentration will be inconsistent and ineffective.

Making the Right Choice for Your Goal

To ensure the success of your PVD process, align your vacuum standards with your specific end-goals:

- If your primary focus is Lattice Structure: Prioritize high vacuum to maximize the mean free path, ensuring doping elements integrate perfectly into the crystal structure.

- If your primary focus is Biomedical Safety: Ensure your system can reach ultra-high vacuum levels to eliminate all traces of oxidation and chemical contamination.

A robust high-vacuum system is not just an operational requirement; it is the primary control variable for film quality and performance.

Summary Table:

| Feature | Impact of High Vacuum | Risk of Inadequate Vacuum |

|---|---|---|

| Particle Path | Minimizes collisions; allows direct ballistic transport | Scattering of atoms; loss of kinetic energy |

| Doping Precision | Uniform integration into the crystal lattice | Compositional drift and inconsistent doping |

| Chemical Purity | Prevents oxidation and environmental contamination | Formation of impurities; altered stoichiometry |

| Film Structure | High density, defect-free, and stable | Porous films with poor substrate adhesion |

Elevate Your Thin Film Precision with KINTEK

High-performance PVD processes demand a pristine vacuum environment to ensure the integrity of nanometer-scale coatings. KINTEK provides the advanced technology necessary to achieve the high-vacuum standards required for doped hydroxyapatite and other sensitive materials.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique laboratory or industrial needs. Whether you are focusing on biomedical safety or lattice structure perfection, our systems provide the reliability you need for high-density, defect-free films.

Ready to optimize your deposition quality? Contact our experts today to find the perfect customizable high-temperature or vacuum furnace for your research.

Visual Guide

References

- Liviu Duta, Valentina Grumezescu. The Effect of Doping on the Electrical and Dielectric Properties of Hydroxyapatite for Medical Applications: From Powders to Thin Films. DOI: 10.3390/ma17030640

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are the advantages of using a vacuum drying oven for t-BTO nanoparticles? Preserve Critical Material Integrity

- What are the applications of high-temperature vacuum sintering furnaces? Essential for Aerospace, Electronics, and Medical Materials

- What are graphite retorts used for in vacuum furnaces? A Guide to High-Temperature Processing

- What is the necessity of using a high-vacuum drying oven? Preserve Electrospun Fiber Morphology and Integrity

- Why is precise temperature control in a vacuum debinding furnace critical? Ensure Integrity of Porous Tungsten

- Which metals are prone to oxidation during melting? Protect with vacuum or inert gas furnaces

- What operational advantages does a vacuum heat treatment furnace offer? Achieve Superior Metallurgical Quality and Precision

- What is the difference between hardening and vacuum hardening? Achieve Superior, Clean Metal Parts