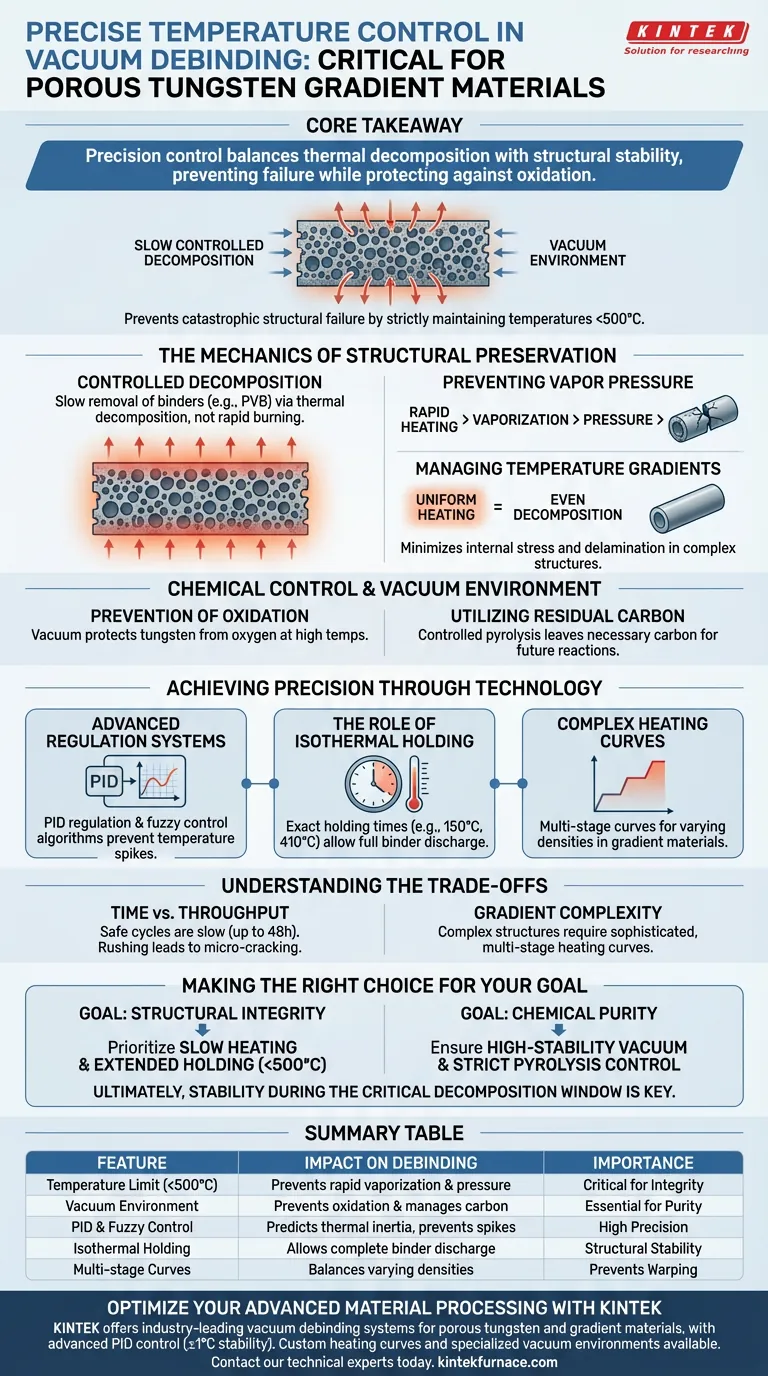

Precise temperature control prevents catastrophic structural failure. By strictly maintaining temperatures below 500°C, the furnace ensures the slow, controlled decomposition of organic binders like Polyvinyl Butyral (PVB). This prevents the rapid vaporization that causes internal pressure buildup and subsequent cracking in porous tungsten green bodies.

Core Takeaway The success of debinding porous tungsten lies in balancing thermal decomposition with structural stability. Precision control acts as a governor, ensuring binder removal is gradual enough to preserve the green body's integrity while the vacuum environment protects the metal from oxidation and manages carbon levels for future reactions.

The Mechanics of Structural Preservation

Controlled Decomposition of Binders

The primary goal during debinding is the removal of organic agents, such as PVB and plasticizers. This process must occur through slow thermal decomposition rather than rapid burning or boiling.

Preventing Vapor Pressure Buildup

If the temperature rises too quickly or fluctuates, organic matter vaporizes instantly. In a porous gradient material, this gas cannot escape fast enough. The resulting internal pressure leads to green body cracking, destroying the part before sintering begins.

Managing Temperature Gradients

Complex porous structures are susceptible to internal stress. Precise regulation minimizes temperature gradients across the part. This uniformity ensures that the binder decomposes evenly throughout the structure, preventing delamination or warping.

Chemical Control and the Vacuum Environment

Prevention of Oxidation

Tungsten is highly sensitive to oxygen at elevated temperatures. Debinding in a vacuum environment is critical to prevent the oxidation of metal elements. Even minor temperature overshoots could accelerate unwanted chemical reactions if the vacuum integrity is compromised.

Utilizing Residual Carbon

The process is not just about removal; it is about chemical balance. Controlled pyrolysis allows for a specific amount of residual carbon to remain. This carbon serves as a necessary source for subsequent in-situ reactions, influencing the final material properties.

Achieving Precision Through Technology

Advanced Regulation Systems

To maintain the strict limits required (often within ±1°C), vacuum furnaces utilize PID regulation and fuzzy control algorithms. These systems predict thermal inertia, preventing the temperature from spiking above the critical 500°C threshold.

The Role of Isothermal Holding

Effective debinding often requires holding the material at specific temperatures (e.g., 150°C or 410°C) for extended periods. Precise control ensures these isothermal holding times are exact, allowing binders to fully discharge from the porous skeleton without stressing the material.

Understanding the Trade-offs

Time vs. Throughput

The most common pitfall is sacrificing precision for speed. A "safe" debinding cycle is inherently slow—sometimes lasting up to 48 hours. Rushing the heating rate to increase throughput almost invariably leads to micro-cracking and rejected parts.

Complexity of Gradient Materials

Porous gradient materials have varying densities and thermal conductivities. A heating curve that works for a solid part may destroy a porous one. The trade-off requires programming complex, multi-stage heating curves rather than simple linear ramps, demanding more sophisticated furnace controls.

Making the Right Choice for Your Goal

To ensure the successful processing of porous tungsten gradient materials, align your process parameters with your specific outcome:

- If your primary focus is Structural Integrity: Prioritize slow heating rates and extended holding times at critical binder decomposition points (e.g., <500°C) to eliminate internal pressure buildup.

- If your primary focus is Chemical Purity: Ensure your system maintains a high-stability vacuum to prevent oxidation and strictly controls pyrolysis to manage residual carbon levels.

Ultimately, precision in debinding is not about how hot you can get, but how stable you can remain during the critical decomposition window.

Summary Table:

| Feature | Impact on Porous Tungsten Debinding | Importance |

|---|---|---|

| Temperature Limit (<500°C) | Prevents rapid PVB vaporization and internal pressure | Critical for Integrity |

| Vacuum Environment | Prevents metal oxidation and manages carbon levels | Essential for Purity |

| PID & Fuzzy Control | Predicts thermal inertia to prevent temperature spikes | High Precision |

| Isothermal Holding | Allows complete binder discharge from porous skeletons | Structural Stability |

| Multi-stage Curves | Balances varying densities in gradient structures | Prevents Warping |

Optimize Your Advanced Material Processing with KINTEK

Don't let structural failures or oxidation compromise your high-performance materials. KINTEK provides industry-leading vacuum debinding systems specifically engineered for the delicate requirements of porous tungsten and gradient materials.

Backed by expert R&D and manufacturing, KINTEK offers a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our furnaces feature advanced PID and fuzzy control logic to ensure the precise ±1°C stability your research demands. Whether you need custom heating curves or specialized vacuum environments, our lab high-temp furnaces are fully customizable to meet your unique processing needs.

Ready to achieve superior thermal precision? Contact our technical experts today to discuss your specific application and discover how KINTEK can enhance your lab's efficiency and success.

Visual Guide

References

- Ke Zhu, Jian Zhang. The Integrated Preparation of Porous Tungsten Gradient Materials with a Wide Porosity Range. DOI: 10.3390/met14040427

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the working environment requirements for a vacuum furnace? Ensure Safety and Purity for Your Lab

- What are the safety considerations when using nitrogen and argon in vacuum furnaces? Prevent Asphyxiation Risks in Your Lab

- What critical process environments does a vacuum annealing furnace provide? Optimize Sm2Fe17Cx Alloy Heat Treatment

- What role does a vacuum annealing furnace play in Bi4I4 single crystals? Master Precise Fermi Level Engineering

- What role does a high-temperature vacuum furnace play in the synthesis of LaTiOC/NdTiOC? Master Heteroanionic Materials

- How does the vacuum pumping system in a vertical vacuum furnace operate? Learn the Multi-Stage Process for Precision

- Why are high-temperature quenching furnaces required for tungsten alloys? Unlock Workability and Stress Relief

- Why Use a Vacuum Annealing Furnace for LPBF Parts? Optimize Stress Relief and Material Purity Today