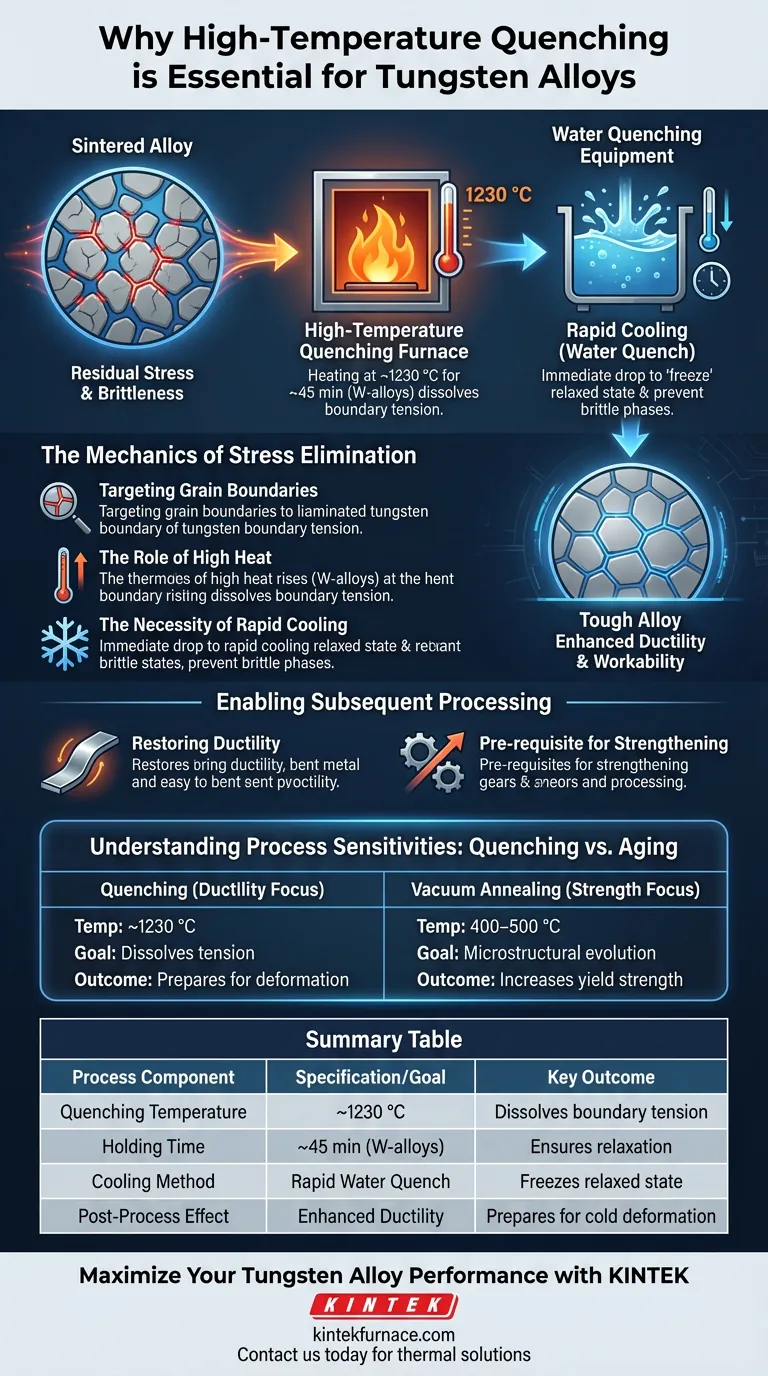

High-temperature quenching furnaces and water quenching equipment are essential for unlocking the mechanical workability of tungsten alloys. These systems function as a critical reset mechanism, heating sintered alloys to specific temperatures (typically 1230 °C) before subjecting them to rapid cooling. This precise thermal cycle is the only effective way to eliminate internal residual stresses found at the structural boundaries of the material, preparing it for further manufacturing.

Core Insight Sintering creates significant stress between the tungsten grains and the binding matrix, limiting the material's flexibility. The quenching process eliminates this stress to stabilize ductility and elongation, transforming the alloy into a tough material capable of withstanding cold deformation strengthening.

The Mechanics of Stress Elimination

Targeting the Grain Boundaries

Tungsten alloys consist of hard tungsten grains embedded in a softer matrix, typically nickel or cobalt. During sintering, substantial residual stresses build up at the boundaries between these two distinct materials.

The Role of High Heat

High-temperature furnaces are required to raise the alloy to approximately 1230 °C. Holding the material at this temperature allows the internal structure to relax, effectively dissolving the tension at the grain-matrix interface.

The Necessity of Rapid Cooling

Water quenching equipment provides the immediate temperature drop required to "freeze" this relaxed state. Rapid cooling prevents the re-formation of deleterious phases that could occur during a slow cool, ensuring the structure remains stable.

Enabling Subsequent Processing

Restoring Ductility

The primary outcome of this thermal treatment is a significant enhancement in ductility and elongation. Without this step, the internal stresses would make the material brittle and prone to fracture under stress.

Pre-requisite for Strengthening

This process is not the final step; it is a preparation stage. By establishing toughness and eliminating brittleness, the quenching process makes it possible to perform cold deformation strengthening later without cracking the material.

Understanding Process Sensitivities

Precision in Holding Times

Precise control over the furnace holding time is critical and varies by chemistry. While tungsten-free alloys may require up to 180 minutes to dissolve secondary carbides, tungsten-containing alloys often require only 45 minutes due to different phase stabilities.

Distinguishing Quenching from Aging

It is vital to distinguish this high-temperature quenching from other treatments. While quenching (at ~1230 °C) builds ductility, vacuum annealing (at 400–500 °C) is used after deformation to increase yield strength and hardness. Confusing these stages will result in immediate material failure or missed mechanical specifications.

Making the Right Choice for Your Goal

To achieve the specific mechanical properties required for high-performance applications like flywheel rotors, you must apply the correct thermal treatment at the correct stage of manufacturing.

- If your primary focus is Workability: Prioritize high-temperature quenching (1230 °C) followed by water cooling to maximize ductility and prepare the alloy for cold deformation.

- If your primary focus is Final Strength: Utilize vacuum annealing (400–500 °C) after forging to trigger microstructural evolution that improves hardness and yield strength.

Success in processing tungsten alloys lies in the disciplined management of heat to balance the competing needs of flexibility during forming and rigidity during application.

Summary Table:

| Process Component | Specification / Goal | Key Outcome |

|---|---|---|

| Quenching Temperature | Approximately 1230 °C | Dissolves boundary tension between grains |

| Holding Time | ~45 Minutes (W-alloys) | Ensures complete internal structure relaxation |

| Cooling Method | Rapid Water Quenching | Freezes relaxed state; prevents brittle phases |

| Post-Process Effect | Enhanced Ductility | Prepares alloy for cold deformation strengthening |

Maximize Your Tungsten Alloy Performance with KINTEK

Don't let residual stress compromise your material integrity. KINTEK’s high-precision thermal solutions are engineered to deliver the exact heating and rapid cooling profiles required for complex tungsten alloy processing.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific lab or industrial requirements. Whether you are aiming to enhance ductility through high-temp quenching or maximize yield strength with vacuum annealing, our equipment ensures consistent, repeatable results.

Ready to optimize your heat treatment workflow? Contact us today to consult with our technical team and find the perfect furnace for your unique needs.

Visual Guide

References

- Adéla Macháčková, Silvie Brožová. Applications of Tungsten Pseudo-Alloys in the Energy Sector. DOI: 10.3390/app14020647

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a laboratory vacuum oven with nitrogen protection used for alumina dehydration? Ensure High-Purity Surfaces

- What technical requirements must a furnace meet for Inconel 718 hardening? Master Precision Aging & Cooling

- Why is a laboratory vacuum environment critical for A357 aluminum alloy sintering? Achieve High-Density Performance

- What processes can be performed inside a vacuum furnace? Unlock Clean, High-Strength Thermal Processing

- How does graphite's thermal conductivity improve vacuum furnace performance? Achieve Superior Thermal Uniformity

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes

- How does precision control in customized vacuum sintering furnaces benefit sintering? Achieve Superior Material Properties and Process Efficiency

- What function does a vacuum chamber serve in the inkjet printing process for perovskite thin films? Expert Insights