Precision control in a customized vacuum sintering furnace is the defining factor in achieving superior material properties, process repeatability, and structural integrity. By giving an operator exact command over the thermal and atmospheric environment, it transforms the sintering process from a simple heat treatment into a highly refined engineering tool, eliminating variables that cause defects and inconsistency.

The core challenge in sintering is not just applying heat, but controlling the entire environment at a microscopic level. Precision control provides this by removing atmospheric contaminants and managing the thermal cycle with exactness, ensuring the final part meets its designed specifications without fail.

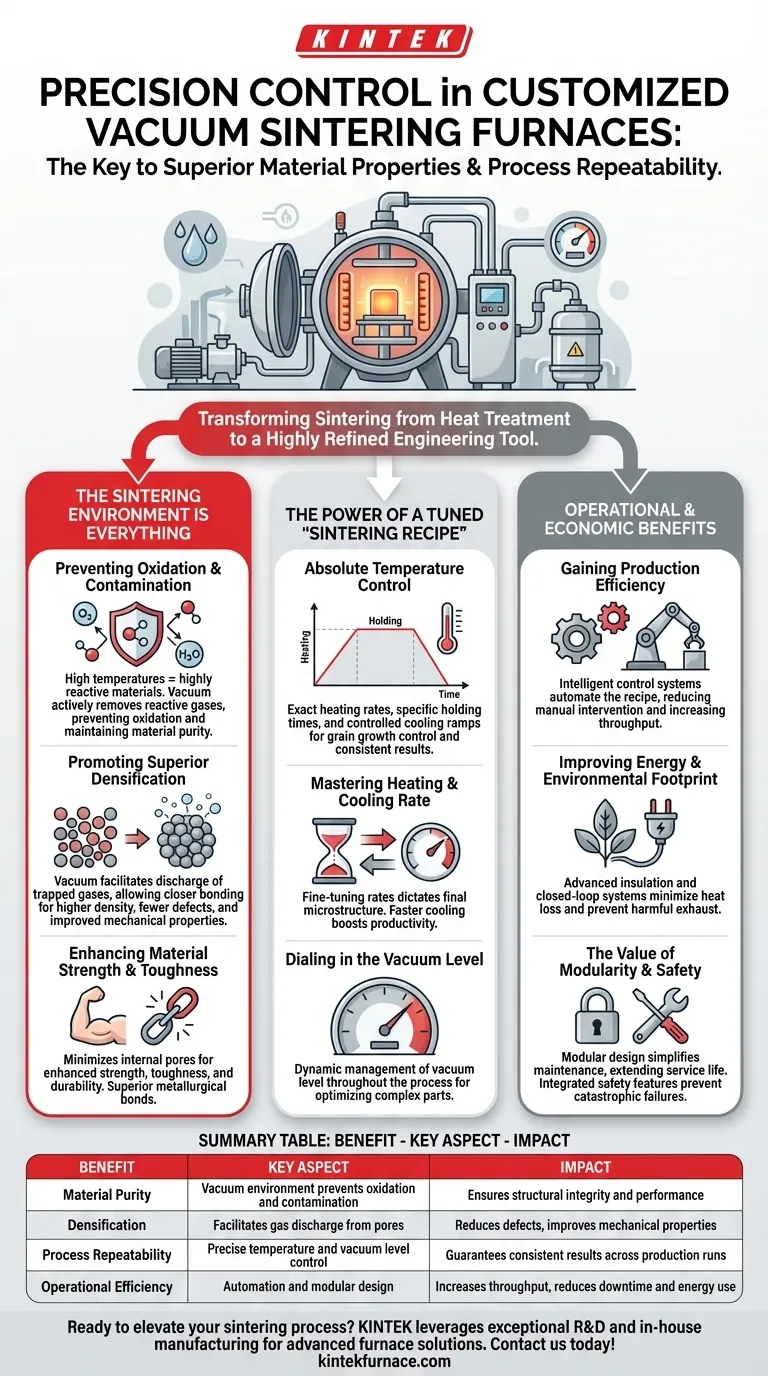

Why the Environment is Everything in Sintering

The quality of a sintered part is determined long before it reaches its peak temperature. The atmospheric conditions during the entire heating and cooling cycle are critical.

Preventing Oxidation and Contamination

At high temperatures, most advanced materials are highly reactive. Any exposure to oxygen or even trace amounts of water vapor can cause oxidation, which compromises the material's structural integrity and performance.

A precisely controlled vacuum environment actively removes these reactive gases. This maintains the purity of the material, preventing the formation of unwanted oxides and ensuring the final product is free from atmospheric contamination.

Promoting Superior Densification

Sintering works by bonding material particles together, and a key goal is to eliminate the empty spaces, or pores, between them. A vacuum actively helps this process.

As the material heats, gases trapped within these pores expand. A vacuum environment facilitates the discharge of these gases, allowing the particles to bond more closely. This results in a final product with higher density, fewer internal defects, and significantly improved mechanical properties.

Enhancing Material Strength and Toughness

The direct results of preventing contamination and improving densification are measurable improvements in performance.

By minimizing internal pores and ensuring a pure material composition, the finished part exhibits enhanced strength, toughness, and overall durability. The controlled environment directly contributes to superior metallurgical bonds.

The Power of a Tuned "Sintering Recipe"

Customization allows for the creation of a perfect, repeatable process—a "recipe"—for a specific material or component. Precision control is what makes this recipe reliable.

Absolute Temperature Control

Different materials require unique thermal profiles. Precision temperature control allows for exact heating rates, specific holding times at peak temperature, and controlled cooling ramps.

This level of management is crucial for controlling grain growth, ensuring complete sintering, and avoiding thermal shock, guaranteeing consistent results from one production run to the next.

Mastering the Heating and Cooling Rate

The speed at which a part is heated and cooled dictates its final microstructure. A customized furnace enables fine-tuning of these rates.

Faster cooling, often achieved through controlled gas quenching, can lock in desirable material phases and significantly shorten overall cycle times, boosting productivity.

Dialing in the Vacuum Level

Effective control isn't just about achieving a deep vacuum; it's about managing the vacuum level throughout the process.

Certain stages may require a specific partial pressure to facilitate binder removal or control outgassing, while others demand a hard vacuum for final densification. This dynamic control is key to optimizing the process for complex parts.

Understanding the Operational and Economic Benefits

While material quality is paramount, precision control also delivers significant operational advantages that impact the bottom line.

Gaining Production Efficiency

Modern vacuum furnaces are equipped with intelligent control systems that automate the entire sintering recipe. This reduces the need for manual intervention, minimizes the risk of human error, and increases throughput.

Improving Energy and Environmental Footprint

Advanced insulation materials and efficient heating element designs minimize heat loss, reducing overall energy consumption.

Furthermore, the closed-loop vacuum system prevents the release of harmful exhaust gases, making it an environmentally responsible process that avoids the cost of secondary exhaust treatment.

The Value of Modularity and Safety

Customized furnaces are often built with a modular design, which simplifies maintenance, repair, and troubleshooting. This extends the equipment's service life and reduces downtime.

Integrated safety features, such as automatic shut-off mechanisms, protect both operators and the investment by preventing catastrophic failures.

Making the Right Choice for Your Goal

The specific controls you prioritize depend on your primary objective.

- If your primary focus is material purity for sensitive alloys: You need exacting control over the vacuum system to eliminate any risk of oxidation or atmospheric contamination.

- If your primary focus is achieving maximum density and mechanical strength: You need precise, programmable control over temperature profiles and vacuum levels to fully remove internal porosity.

- If your primary focus is high-volume, repeatable production: You need an integrated system with advanced automation and recipe management to ensure every part is identical with minimal operator input.

Ultimately, precision control transforms the vacuum furnace from a simple oven into a sophisticated instrument for advanced material creation.

Summary Table:

| Benefit | Key Aspect | Impact |

|---|---|---|

| Material Purity | Vacuum environment prevents oxidation and contamination | Ensures structural integrity and performance |

| Densification | Facilitates gas discharge from pores | Reduces defects, improves mechanical properties |

| Process Repeatability | Precise temperature and vacuum level control | Guarantees consistent results across production runs |

| Operational Efficiency | Automation and modular design | Increases throughput, reduces downtime and energy use |

Ready to elevate your sintering process with precision control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how our customized vacuum sintering furnaces can enhance your material properties and boost efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments