The primary purpose of using a high-temperature vacuum annealing furnace in Laser Powder Bed Fusion (LPBF) is to eliminate the severe residual thermal stresses caused by the printing process while preserving the material's chemical purity. By subjecting components to sustained heat (such as 630 °C for 10 hours) within a vacuum environment, manufacturers can stabilize the part's geometry and microstructure without the risk of oxidative contamination.

The LPBF process freezes high tension into metal parts due to rapid cooling. Vacuum annealing acts as a necessary "stress-release" mechanism, allowing the material to relax and bond effectively while a vacuum shield prevents oxygen from degrading the surface.

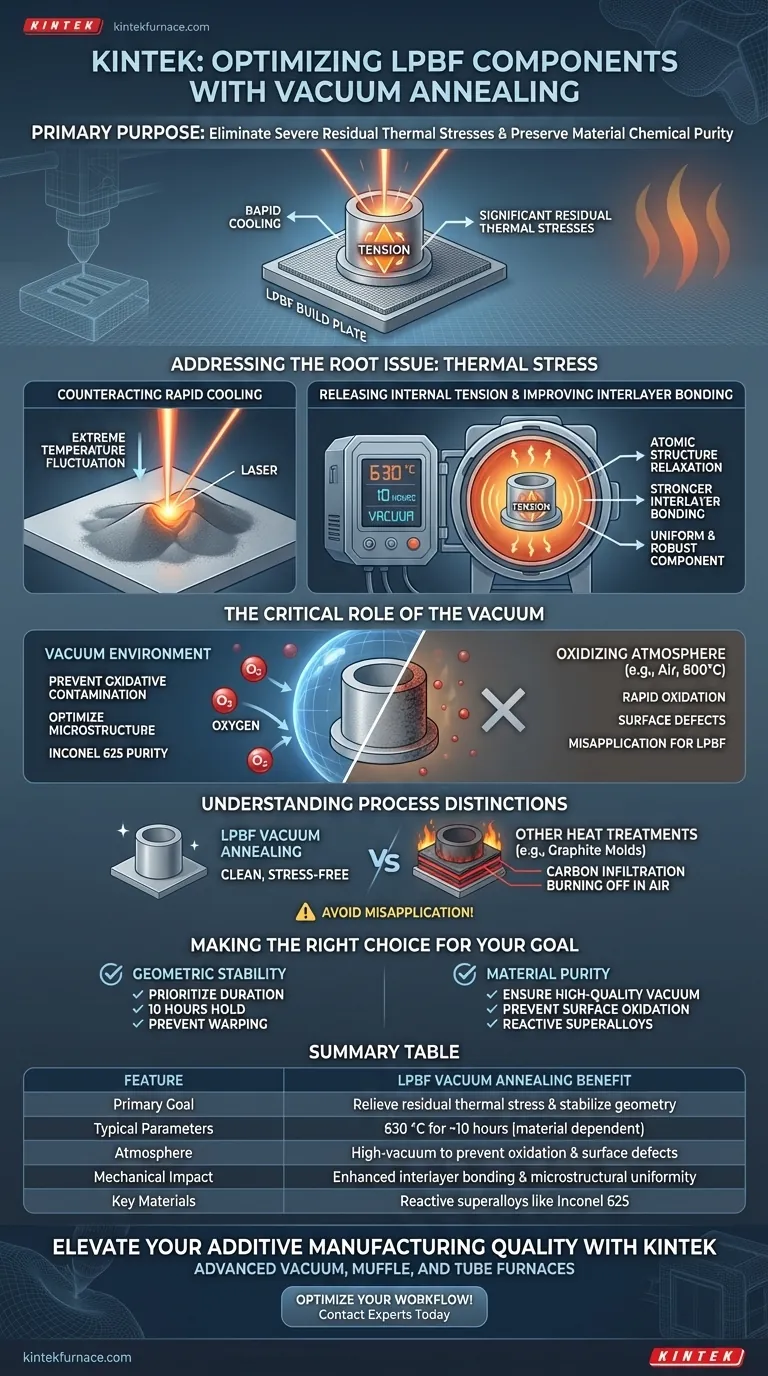

Addressing the Root Issue: Thermal Stress

Counteracting Rapid Cooling

The LPBF process involves melting metal powder with a laser, followed by almost instantaneous solidification. This extreme temperature fluctuation locks significant residual thermal stresses into the structure of the component.

Releasing Internal Tension

To fix this, the component is placed in a furnace and held at a specific high temperature, such as 630 °C, for an extended duration (e.g., 10 hours). This thermal energy allows the atomic structure to relax, effectively releasing the built-up internal pressure that could otherwise lead to warping or failure.

Improving Interlayer Bonding

Beyond simple stress relief, this heat treatment enhances the mechanical cohesion of the part. The sustained heat promotes stronger bonding between the printed layers, resulting in a more uniform and robust component.

The Critical Role of the Vacuum

Preventing Oxidative Contamination

Heating metals to high temperatures in the presence of air typically causes rapid oxidation. The vacuum environment is essential because it removes oxygen from the equation entirely.

Optimizing Microstructure

For high-performance materials like Inconel 625, maintaining material purity is vital. The vacuum ensures that the microstructural organization is optimized during the heating cycle without introducing impurities or surface defects.

Understanding Process Distinctions

Vacuum vs. Oxidizing Atmospheres

It is critical to distinguish LPBF annealing from other heat treatment methods. Some manufacturing processes (such as those using graphite molds) actually require an oxidizing atmosphere (air) at high temperatures (e.g., 800 °C) to burn off carbon infiltration layers.

Avoid Misapplication

Applying an oxidizing atmosphere to an LPBF metal part would be a mistake. Unlike molded ceramics or binder-jet parts that may need to shed carbon, LPBF metal parts require strict protection from oxidation to maintain their mechanical properties.

Making the Right Choice for Your Goal

To ensure your LPBF components perform as intended, align your post-processing parameters with your specific material requirements.

- If your primary focus is Geometric Stability: Prioritize the duration of the heat hold (e.g., 10 hours) to fully relieve residual stresses and prevent future warping.

- If your primary focus is Material Purity: Ensure your furnace maintains a high-quality vacuum to prevent surface oxidation, especially when working with reactive superalloys like Inconel 625.

Proper vacuum annealing turns a printed shape into a reliable, engineering-grade component.

Summary Table:

| Feature | LPBF Vacuum Annealing Benefit |

|---|---|

| Primary Goal | Relieve residual thermal stress & stabilize geometry |

| Typical Parameters | 630 °C for ~10 hours (material dependent) |

| Atmosphere | High-vacuum to prevent oxidation & surface defects |

| Mechanical Impact | Enhanced interlayer bonding & microstructural uniformity |

| Key Materials | Reactive superalloys like Inconel 625 |

Elevate Your Additive Manufacturing Quality with KINTEK

Don't let residual stress or oxidation compromise your high-performance LPBF components. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced Vacuum, Muffle, and Tube furnaces specifically designed to stabilize your 3D-printed parts. Whether you need precise stress relief for Inconel 625 or customizable thermal cycles for unique alloys, our systems ensure maximum material purity and geometric integrity.

Ready to optimize your post-processing workflow? Contact our technical experts today to find the perfect customizable furnace solution for your laboratory or production facility.

Visual Guide

References

- Kaicheng Xu, Xuezheng Yue. Deformation Behavior of Inconel 625 Alloy with TPMS Structure. DOI: 10.3390/ma18020396

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does PCA play in monitoring industrial furnace sensors? Enhance Fault Detection & Diagnostic Accuracy

- How does the heating mechanism of an SPS furnace benefit CNT copper composites? Preserve Nanostructures with Rapid Heat

- What feature of vacuum furnaces makes them suitable for large-scale manufacturing? Unmatched Scalability & Reproducibility

- What benefits does vacuum provide in a vacuum brazing furnace? Achieve Stronger, Cleaner Joints with Precision

- Why is a laboratory vacuum oven necessary for drying degraded LTGP samples? Ensure Pure Surface Analysis Results

- What heating method is proposed for the vacuum chamber? Efficient Direct Resistive Heating Explained

- How is a directional solidification furnace used to remove metallic impurities from silicon? Achieve Solar-Grade Purity

- How are vacuum furnaces classified based on chamber design? Explore Horizontal, Vertical, and Bottom-Loading Types