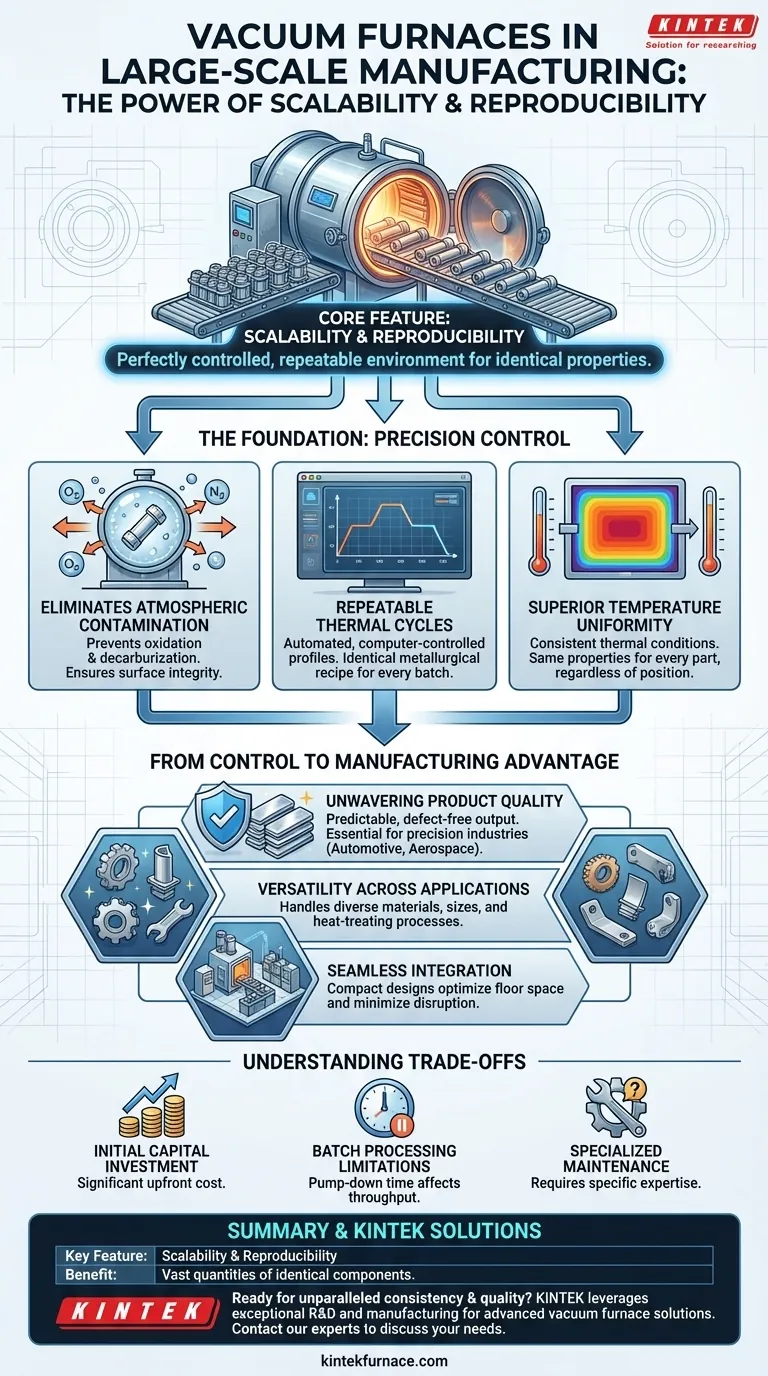

The defining feature of vacuum furnaces that makes them ideal for large-scale manufacturing is their exceptional scalability and reproducibility. This allows them to produce vast quantities of components with virtually identical material properties, a critical requirement in precision industries like automotive and aerospace.

The core reason vacuum furnaces excel at scale is not just their size, but their ability to create a perfectly controlled and repeatable environment. By removing atmospheric variables, they ensure that every single batch undergoes the exact same treatment, guaranteeing unparalleled consistency.

The Foundation of Scalability: Precision Control

The ability to reproduce parts reliably stems from the furnace's precise control over the heat treatment environment. This control eliminates the variables that cause defects and inconsistencies in traditional atmospheric furnaces.

Eliminating Atmospheric Contamination

A vacuum environment removes active gases like oxygen. This prevents unwanted chemical reactions such as oxidation and decarburization, ensuring the material's surface integrity and properties are maintained exactly as intended.

Creating Repeatable Thermal Cycles

Modern vacuum furnaces are automated to execute pre-programmed thermal cycles with extreme precision. The heating rates, soak times, and cooling profiles are managed by computer control, ensuring every batch follows the identical metallurgical recipe.

Ensuring Uniform Temperature

These furnaces are engineered for superior temperature uniformity throughout the hot zone. This means every part in a large batch, regardless of its position, experiences the same thermal conditions, resulting in consistent hardness, grain structure, and other critical properties.

From Control to Manufacturing Advantage

This level of environmental control translates directly into tangible benefits on the factory floor, justifying their use in demanding, high-volume production.

Unwavering Product Quality

The primary benefit is predictable, high-quality output. For industries where component failure is not an option, the ability to produce thousands of identical, defect-free parts is the most important factor.

Versatility Across Applications

A single vacuum furnace can handle a wide variety of materials, component sizes, and heat-treating processes. This flexibility makes it a valuable asset in a dynamic manufacturing environment, capable of adapting to changing production needs.

Seamless Integration

Many designs, particularly horizontal vacuum furnaces, are engineered to be compact. This facilitates easier integration into existing and often crowded manufacturing facilities, minimizing disruption and optimizing floor space.

Understanding the Trade-offs

While powerful, vacuum furnaces are a strategic investment with specific operational considerations.

Initial Capital Investment

Vacuum furnaces represent a significant upfront cost compared to their atmospheric counterparts. The technology for creating and maintaining a high-quality vacuum adds to the initial expense.

Batch Processing Limitations

Vacuum furnaces operate on a batch-by-batch basis. The time required to pump down the chamber to the required vacuum level is a fixed part of the cycle, which can influence overall throughput compared to continuous-style furnaces.

Specialized Maintenance

While routine maintenance can be straightforward, the vacuum systems themselves require specialized knowledge for troubleshooting and repair. This necessitates either in-house expertise or a reliable service partner.

Making the Right Choice for Your Goal

To determine if a vacuum furnace is the correct solution, align its capabilities with your primary production driver.

- If your primary focus is meeting strict quality standards at high volume: The unparalleled reproducibility of a vacuum furnace is the most reliable way to ensure every part meets specification.

- If your primary focus is production flexibility: The furnace's ability to handle diverse materials, geometries, and processes provides maximum utility for varied manufacturing demands.

- If your primary focus is floor-space efficiency: The compact design of many horizontal models allows for powerful heat-treating capabilities without requiring excessive facility space.

Ultimately, choosing a vacuum furnace is a decision to prioritize absolute control and consistency in your manufacturing process.

Summary Table:

| Key Feature | Benefit for Large-Scale Manufacturing |

|---|---|

| Scalability & Reproducibility | Produces vast quantities of components with identical material properties. |

| Eliminates Atmospheric Contamination | Prevents oxidation and decarburization, ensuring surface integrity. |

| Repeatable Thermal Cycles | Automated, precise control guarantees every batch follows the same recipe. |

| Superior Temperature Uniformity | Consistent thermal conditions for every part in a large load. |

Ready to achieve unparalleled consistency and quality in your large-scale manufacturing?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced vacuum furnace solutions. Our product line, including high-performance Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique production requirements for scalability and reproducibility.

Contact our experts today to discuss how a KINTEK vacuum furnace can become the cornerstone of your quality-driven manufacturing process.

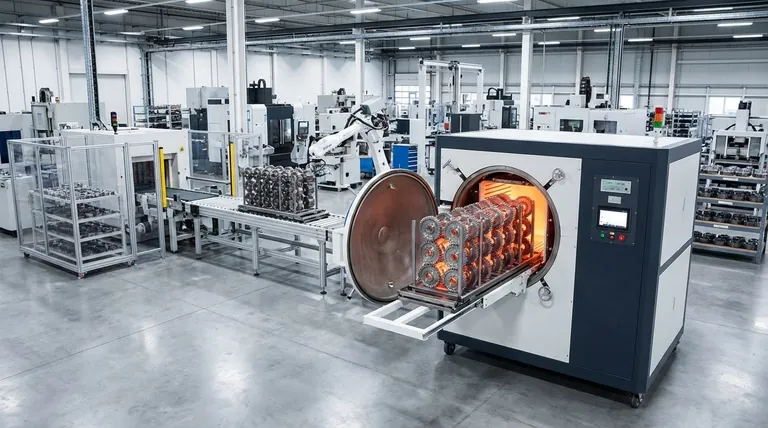

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability