At its core, the vacuum in a brazing furnace creates a pristine, highly controlled environment that is impossible to achieve by other means. This active removal of gases prevents oxidation, purifies the parent materials by drawing out trapped impurities, and promotes the ideal flow of brazing filler metal, resulting in exceptionally strong and reliable joints.

The fundamental purpose of the vacuum is not simply to remove air, but to gain absolute control over the brazing environment. This control allows you to eliminate invisible contaminants and chemical reactions that compromise joint integrity, ensuring a level of quality and repeatability that is critical for high-performance applications.

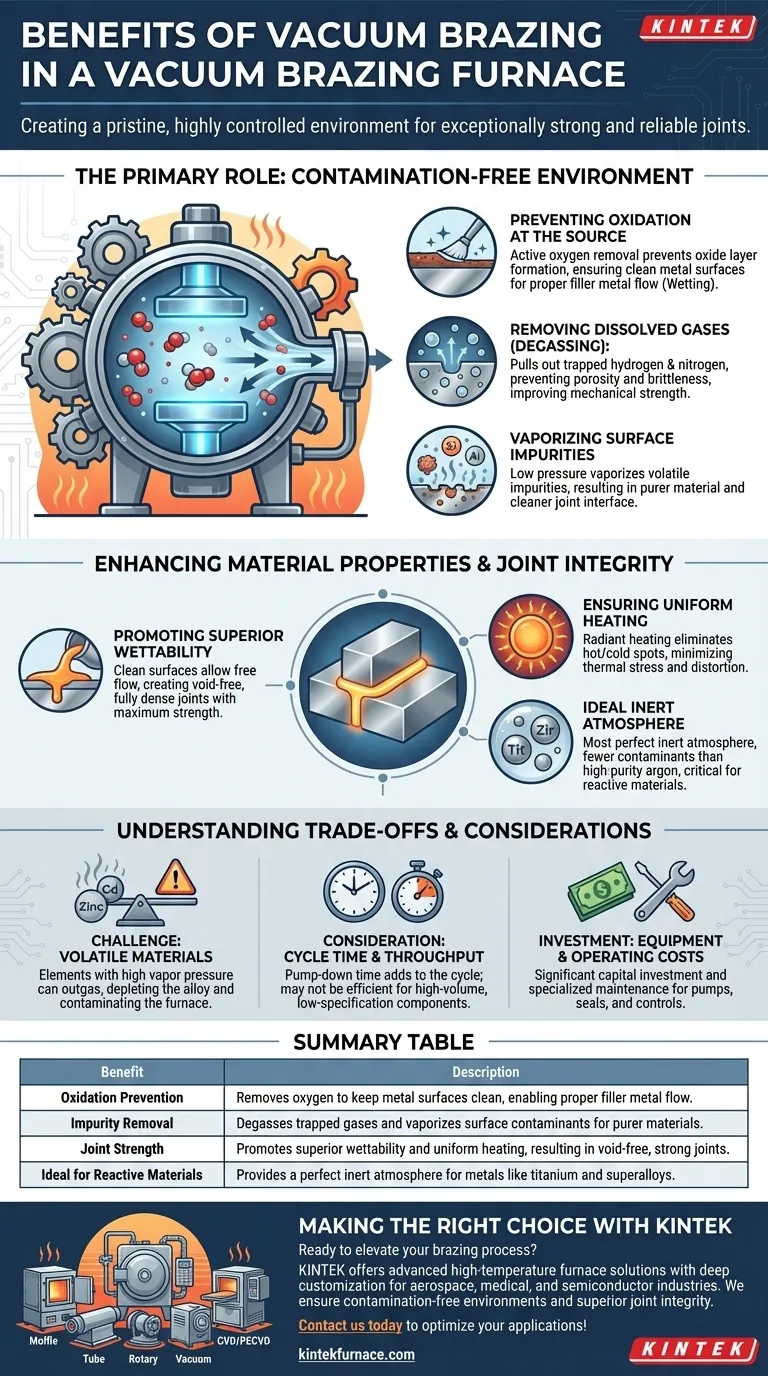

The Primary Role: Creating a Contamination-Free Environment

A vacuum furnace's most significant benefit is its ability to engineer a chemically pure workspace. This isn't just a passive "inert" atmosphere; it's an active process of purification.

Preventing Oxidation at the Source

Oxygen is the primary enemy of a strong braze joint. Even trace amounts react with hot metal surfaces to form oxides.

These oxide layers act as a barrier, preventing the molten filler metal from properly adhering to and flowing across the parent materials—a process known as wetting. A vacuum physically removes the oxygen, ensuring the metal surfaces remain perfectly clean.

Removing Dissolved Gases (Degassing)

Metals inherently contain dissolved gases like hydrogen and nitrogen trapped within their structure. Under the low-pressure conditions of a vacuum, these gases are pulled out of the material.

This degassing effect is critical because it prevents porosity and brittleness in the final joint, significantly improving its mechanical strength and hardness.

Vaporizing Surface Impurities

The low pressure inside a vacuum furnace reduces the boiling point of many elements. This allows the furnace to effectively "boil off" and remove volatile impurities from the surface of the parts.

Elements like silicon, aluminum, and other contaminants are eliminated, resulting in a purer material quality and a cleaner joint interface.

Enhancing Material Properties and Joint Integrity

By creating this ideal environment, the vacuum directly contributes to a superior final product. The benefits extend beyond cleanliness to the fundamental metallurgical properties of the joint itself.

Promoting Superior Wettability

With no oxide layers to interfere, the molten braze filler metal can flow freely and uniformly into the joint gap through capillary action.

This excellent wettability is the single most important factor for creating a void-free, fully dense joint with maximum surface contact and strength.

Ensuring Uniform Heating

In a vacuum, heat transfer occurs primarily through radiation, not convection. This eliminates the hot and cold spots caused by circulating gas currents.

The result is exceptionally uniform heating, which minimizes thermal stress on the assembly, reduces the risk of distortion, and is essential when joining materials with different thermal expansion rates.

Serving as an Ideal Inert Atmosphere

For all practical purposes, a deep vacuum is the most perfect inert atmosphere possible. It contains fewer contaminating molecules per cubic centimeter than even the highest-purity argon or nitrogen.

This makes it the go-to process for highly reactive materials like titanium, zirconium, and superalloys, which would be compromised by any atmospheric exposure at brazing temperatures.

Understanding the Trade-offs and Process Considerations

While powerful, vacuum brazing is not the universal solution for every application. Understanding its limitations is key to making an objective decision.

The Challenge of Volatile Materials

The same principle that removes impurities can also remove desirable elements. Materials containing elements with high vapor pressure, such as zinc, cadmium, or lead, can be problematic.

These elements may outgas from the parent material or filler metal, depleting the alloy and potentially contaminating the furnace interior.

Cycle Time and Throughput

Achieving a deep vacuum is not instantaneous. The pump-down time adds to the overall process cycle, which can be longer than that of an open-air or continuous belt furnace.

For high-volume, low-specification components where speed is paramount, vacuum brazing may not be the most efficient choice.

Equipment and Operating Costs

Vacuum furnaces represent a significant capital investment. They require specialized maintenance for pumps, seals, and control systems to ensure performance and reliability.

The higher initial cost and operational complexity must be weighed against the required level of quality and performance for the final part.

Making the Right Choice for Your Application

Selecting the right process requires aligning its capabilities with your project's most critical goals.

- If your primary focus is maximum joint strength and purity: Vacuum brazing is essential for mission-critical parts in aerospace, medical, and semiconductor applications where failure is not an option.

- If your primary focus is joining reactive or dissimilar materials: The chemically inert environment of a vacuum is the only reliable method for preventing brittle intermetallic compounds when brazing metals like titanium or superalloys.

- If your primary focus is high-volume, lower-cost production: For non-critical components, simpler methods like controlled atmosphere (nitrogen/hydrogen) or torch brazing may offer a more cost-effective solution with faster throughput.

Ultimately, choosing to use a vacuum is a decision to prioritize metallurgical perfection over process speed or initial cost.

Summary Table:

| Benefit | Description |

|---|---|

| Oxidation Prevention | Removes oxygen to keep metal surfaces clean, enabling proper filler metal flow. |

| Impurity Removal | Degasses trapped gases and vaporizes surface contaminants for purer materials. |

| Joint Strength | Promotes superior wettability and uniform heating, resulting in void-free, strong joints. |

| Ideal for Reactive Materials | Provides a perfect inert atmosphere for metals like titanium and superalloys. |

Ready to elevate your brazing process with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, medical, or semiconductor industries, our vacuum brazing furnaces ensure contamination-free environments and superior joint integrity. Contact us today to discuss how we can optimize your brazing applications and drive your success!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering