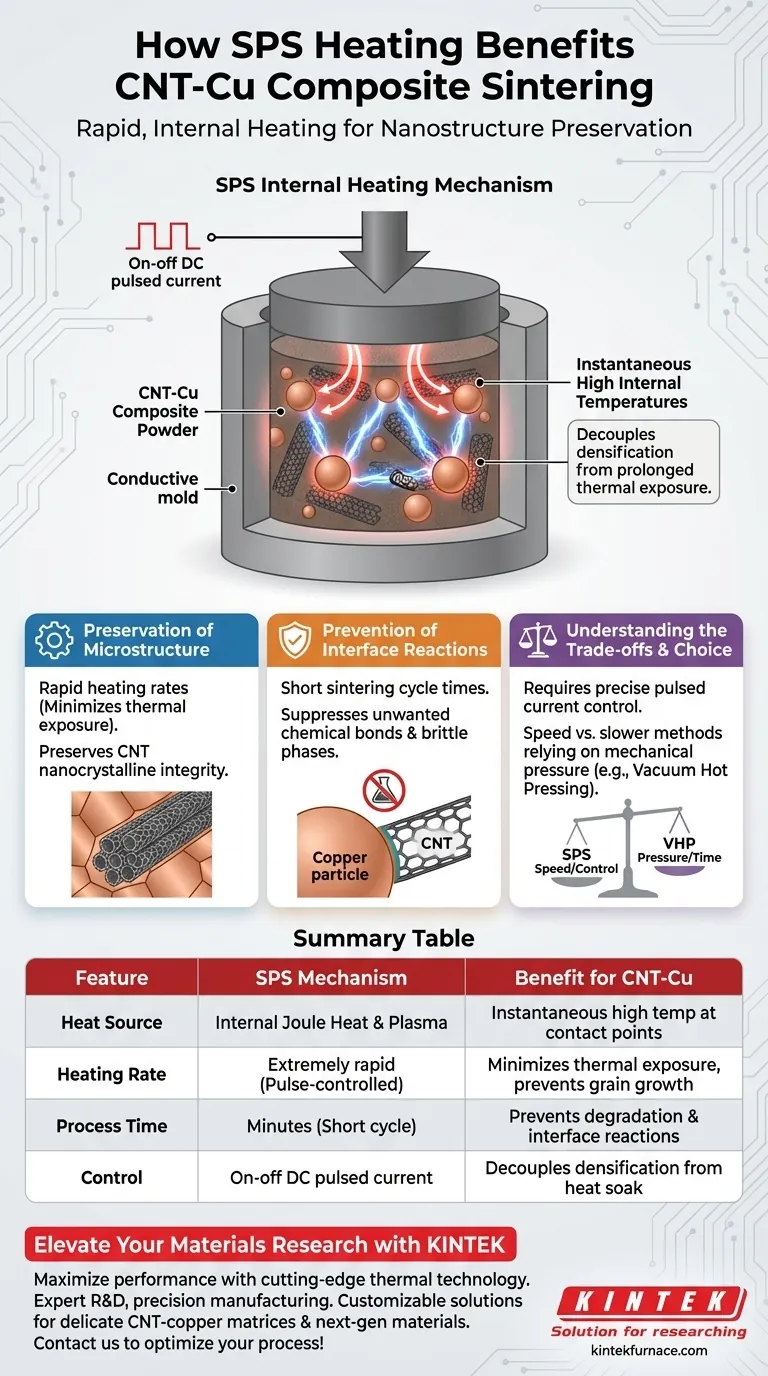

The Spark Plasma Sintering (SPS) furnace utilizes an on-off DC pulsed current to generate heat directly within the composite material. By passing this current through the powder particles and molds, the system creates discharge plasma and internal Joule heat. This mechanism achieves instantaneous high temperatures and extremely rapid heating rates, allowing for densification to occur in a fraction of the time required by traditional methods.

Core Takeaway The unique internal heating mechanism of SPS is critical for nanocomposites because it decouples densification from prolonged thermal exposure. By sintering rapidly, it preserves the delicate structure of carbon nanotubes and prevents degrading interface reactions, ensuring the final copper matrix retains its enhanced mechanical properties.

The Mechanics of Internal Heating

Direct Current Passage

Unlike conventional furnaces that heat material from the outside in, SPS drives on-off DC pulsed current directly through the powder particles and the conductive mold.

This internal generation of energy ensures that the heat is localized exactly where it is needed—at the particle contact points.

Generation of Joule Heat and Plasma

The current passing through the contact points generates significant Joule heat due to electrical resistance.

Simultaneously, the gaps between particles facilitate the generation of discharge plasma. This combination results in instantaneous high internal temperatures that trigger rapid sintering mechanisms.

Preservation of Material Microstructure

Minimizing Thermal Exposure

The most critical advantage of the SPS heating mechanism is the extreme reduction in processing time.

Because the heating rates are so rapid, the material reaches its sintering temperature and densifies quickly. This minimizes the "soak time" that the copper and carbon nanotubes are exposed to peak temperatures.

Protecting CNT Integrity

Carbon nanotubes (CNTs) are thermally sensitive and can degrade or react chemically if held at high temperatures for too long.

By completing densification in a very short time, SPS preserves the nanocrystalline structure of the matrix and the integrity of the CNT reinforcement.

Preventing Interface Reactions

Extended sintering times often lead to unwanted chemical reactions at the interface between the copper matrix and the carbon nanotubes.

The rapid nature of the SPS pulsed current mechanism avoids these excessive interface reactions, ensuring that the bond between the matrix and the reinforcement remains strong without forming brittle or degrading phases.

Understanding the Trade-offs

Process Control vs. Speed

While the rapid heating of SPS is beneficial, it requires precise control over the current parameters.

The very speed that protects the CNTs leaves a narrower window for error compared to methods like Vacuum Hot Pressing, which relies on slower, time-dependent plastic flow and rearrangement.

Heating vs. Pressure Reliance

SPS relies heavily on electrical effects (plasma/Joule heat) to drive sintering.

In contrast, techniques like Vacuum Hot Pressing rely more on high uniaxial mechanical pressure (e.g., 30 MPa) to forcibly eliminate voids and promote plastic flow. While SPS achieves density quickly, understanding the interplay between the electrical heating and the applied pressure is vital for consistent results.

Making the Right Choice for Your Goal

To maximize the performance of your carbon nanotube copper matrix composites, align your processing parameters with your specific material needs:

- If your primary focus is preserving nanostructure: Prioritize the rapid heating rates of SPS to minimize thermal exposure and maintain CNT integrity.

- If your primary focus is avoiding chemical degradation: Utilize the short sintering cycles of SPS to suppress interface reactions between the copper and carbon.

- If your primary focus is pure densification via deformation: Acknowledge that while SPS is fast, supplementary pressure (similar to Vacuum Hot Pressing) assists in eliminating voids in difficult-to-sinter systems.

By leveraging the internal, pulsed-current heating of SPS, you can achieve high-density composites without sacrificing the unique properties of the carbon nanotubes.

Summary Table:

| Feature | SPS Heating Mechanism | Benefit for CNT-Cu Composites |

|---|---|---|

| Heat Source | Internal Joule Heat & Discharge Plasma | Instantaneous high temperatures at contact points |

| Heating Rate | Extremely rapid pulse-controlled | Minimizes thermal exposure and prevents grain growth |

| Process Time | Minutes (Short cycle) | Prevents degradation and unwanted interface reactions |

| Control | On-off DC pulsed current | Decouples densification from prolonged heat soak |

Elevate Your Materials Research with KINTEK

Maximize the performance of your advanced composites by leveraging KINTEK’s cutting-edge thermal technology. Backed by expert R&D and precision manufacturing, we provide a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temp lab furnaces tailored to your unique research needs.

Whether you are sintering delicate CNT-copper matrices or developing next-gen nanocrystalline materials, our customizable solutions ensure optimal grain control and structural integrity. Ready to optimize your sintering process? Contact us today to speak with our technical specialists!

Visual Guide

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does an industrial-grade vacuum furnace play in the brazing process of MnCoNiCuGe5 high-entropy alloys?

- Why is a vacuum oven used for drying ionogels? Preserve Structural Integrity for Precise Electron Microscopy

- What critical conditions does a vacuum sintering furnace provide for cemented carbides? Ensuring Peak Material Density

- How does the design of a large-scale laboratory vacuum unit prevent secondary contamination? Isolation via Quartz Screens

- How does industrial thermal analysis simulation software optimize directional solidification? Elevate Casting Precision

- What are the benefits of using graphite heating elements in vacuum furnaces? Achieve Extreme Heat and Durability

- Why is a high-pressure reactor core equipment for hydrothermal carbonization? Unlock Superior Carbon Skeletons

- What are the characteristics of vacuum heat treatment? Unlock Superior Material Performance and Control