At its core, vacuum heat treatment is the process of heating and cooling metals inside a furnace where the atmosphere has been evacuated to a near-vacuum. This fundamental change—removing oxygen and other reactive gases—prevents surface reactions like oxidation and decarbonization. The result is a component with an inherently clean, bright surface and superior, uniformly enhanced mechanical properties such as hardness and toughness.

The fundamental advantage of vacuum heat treatment is not just about creating a clean part; it is about achieving unparalleled process control. By removing atmospheric variables, the process delivers exceptional uniformity and repeatability, leading to higher-performing and more reliable components.

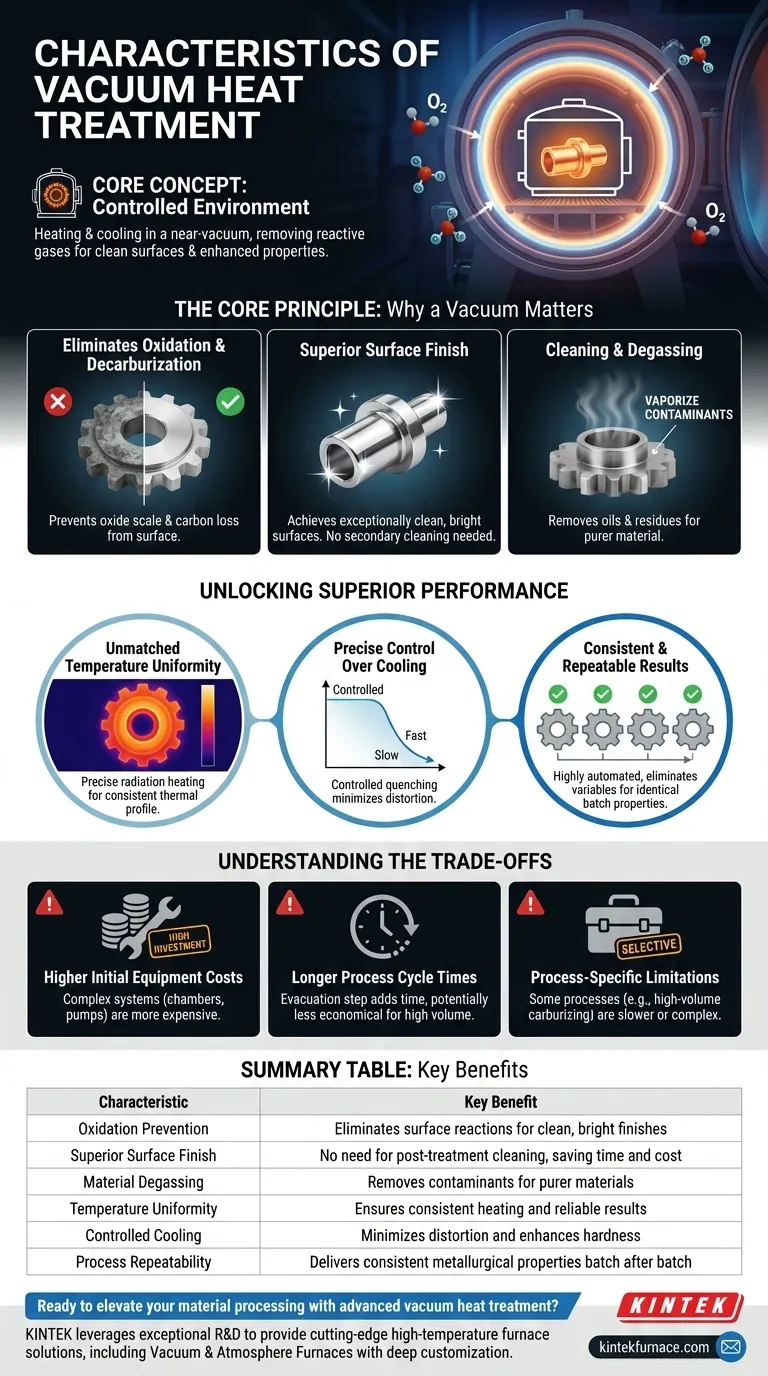

The Core Principle: Why a Vacuum Matters

The defining characteristic of this process is the controlled environment. Removing the atmosphere fundamentally changes how heat affects the material, unlocking significant benefits that are difficult to achieve with conventional methods.

Eliminating Oxidation and Decarburization

In a traditional furnace, the oxygen in the air reacts with the hot metal surface, forming a layer of oxide scale. A vacuum environment, by definition, lacks sufficient oxygen for this reaction to occur. This completely prevents oxidation and the loss of carbon from the steel's surface (decarburization).

Achieving a Superior Surface Finish

A direct result of preventing oxidation is an exceptionally clean and bright surface on the finished part. Components emerge from the furnace with the same surface finish they had going in, eliminating the need for costly and time-consuming secondary operations like sandblasting or chemical cleaning.

Cleaning and Degassing the Material

The combination of high heat and low pressure can cause surface contaminants, such as oils or cleaning residues, to vaporize. This "cleaning" effect results in a purer material and is critical for applications like vacuum brazing or medical implants.

Unlocking Superior Material Performance

Process control is where vacuum treatment truly excels. The vacuum allows for thermal management that is simply not possible in a conventional furnace, leading to significant improvements in a material's final properties.

Unmatched Temperature Uniformity

Heating in a vacuum is primarily achieved through radiation. This allows for extremely uniform and precise temperature control throughout the entire workload. Every part, regardless of its position in the furnace, experiences the same thermal profile, ensuring consistent results.

Precise Control Over Cooling

Quenching (rapid cooling) is critical for developing hardness. Vacuum furnaces allow for highly controlled quenching using inert gas, oil, or even water. This precision minimizes thermal shock and distortion, which is especially important for complex or delicate geometries.

Consistent and Repeatable Results

Because variables like atmospheric composition are eliminated, the process is highly automated and repeatable. The combination of uniform heating and controlled cooling ensures that every part in a batch, and every subsequent batch, achieves the exact same metallurgical properties.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not a universal solution. An objective evaluation requires acknowledging its specific costs and constraints.

Higher Initial Equipment Costs

Vacuum furnaces are complex systems involving sealed chambers, powerful pumps (backing, booster, and diffusion pumps), and sophisticated controls. This makes them significantly more expensive to purchase and maintain than standard atmospheric furnaces.

Longer Process Cycle Times

The step of evacuating the furnace to create a vacuum adds time to the beginning of every cycle. For certain low-value, high-volume parts, the longer cycle time may make the process less economical than faster atmospheric treatments.

Process-Specific Limitations

While versatile, some thermochemical processes like high-volume carburizing can be slower or more complex to perform in a vacuum compared to established atmospheric methods. The choice depends on the specific material, part geometry, and desired outcome.

Making the Right Choice for Your Application

Choosing vacuum heat treatment depends entirely on the required quality, performance, and cost constraints of your final component. It is a decision about investing in final-part integrity.

- If your primary focus is surface finish and cosmetics: Vacuum treatment is the definitive choice, as it eliminates the need for any post-process cleaning or descaling.

- If your primary focus is maximum performance and reliability: The precise thermal control of a vacuum furnace delivers the uniform microstructure and consistent mechanical properties required for critical applications.

- If your primary focus is cost-sensitive, mass production of simple parts: Traditional atmospheric treatment may be a more economical solution, provided the part can tolerate some surface oxidation and less-precise properties.

Ultimately, investing in vacuum heat treatment is an investment in process control and final part quality.

Summary Table:

| Characteristic | Key Benefit |

|---|---|

| Oxidation Prevention | Eliminates surface reactions for clean, bright finishes |

| Superior Surface Finish | No need for post-treatment cleaning, saving time and cost |

| Material Degassing | Removes contaminants for purer materials |

| Temperature Uniformity | Ensures consistent heating and reliable results |

| Controlled Cooling | Minimizes distortion and enhances hardness |

| Process Repeatability | Delivers consistent metallurgical properties batch after batch |

Ready to elevate your material processing with advanced vacuum heat treatment? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering unparalleled process control and superior part quality. Contact us today to discuss how our tailored solutions can optimize your heat treatment processes and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision