Principal Component Analysis (PCA) serves as the primary filter for managing the massive data overload in industrial furnace monitoring. It functions by applying dimension reduction techniques to data from thousands of sensors, effectively isolating critical variables from background noise. This process transforms raw, redundant information into a clear signal, directly improving fault detection accuracy and suppressing false alarms.

The sheer volume of sensor data in industrial settings often obscures real problems. PCA solves this by extracting only the most vital features, thereby increasing the reliability of anomaly diagnosis to approximately 89%.

The Challenge of Sensor Saturation

Managing Data Volume

Industrial furnaces are complex systems equipped with thousands of sensors. These sensors continuously stream data, creating a dataset so vast that manual monitoring or standard linear analysis becomes inefficient.

The Problem of Redundancy

A significant portion of this generated data is redundant. Multiple sensors often report on correlated variances, creating "noise" that complicates the identification of distinct performance issues.

How PCA Enhances Monitoring

Dimension Reduction techniques

PCA algorithms address data saturation through dimension reduction. Instead of processing thousands of individual data points, the algorithm compresses this information into a smaller set of "principal components" that retain the essential patterns of the original data.

Critical Feature Extraction

By stripping away the redundancy, PCA isolates the most critical feature variables. This allows the monitoring system to focus its computational power on the specific data trends that actually indicate furnace health.

Improving Fault Detection

Filtering Background Noise

Raw sensor data contains significant background noise—random fluctuations that do not represent actual mechanical or thermal issues. PCA effectively filters this out, preventing the system from interpreting normal operational variance as a problem.

Reducing False Alarms

One of the most valuable outcomes of this noise reduction is a sharp decrease in false alarms. By distinguishing between noise and actual anomalies, operators are only alerted when a genuine deviation occurs.

Quantifiable Reliability

The implementation of PCA has a measurable impact on diagnostic success. By cleaning the data stream, the reliability of furnace anomaly diagnosis is increased to approximately 89%.

Understanding the Trade-offs

The Reliability Gap

While PCA significantly improves performance, the resulting 89% reliability rate implies an 11% margin of error. It is a powerful tool, but not an infallible solution for every possible anomaly.

Loss of Granularity

The process of dimension reduction inherently involves summarizing data. While this removes noise, there is always a theoretical risk that highly subtle, non-redundant signals could be compressed or overlooked if they do not align with the principal components.

Making the Right Choice for Your System

If your primary focus is Noise Reduction: Implement PCA to filter out the random background fluctuations common in high-volume sensor environments.

If your primary focus is Operational Efficiency: Use PCA to drastically reduce false alarms, ensuring your team only reacts to genuine maintenance needs.

If your primary focus is Diagnostic Accuracy: Leverage PCA to achieve an anomaly diagnosis reliability rate of roughly 89%, far surpassing raw data monitoring.

By converting thousands of noisy signals into a streamlined data model, PCA turns sensor overload into actionable diagnostic precision.

Summary Table:

| Feature | Impact of PCA on Furnace Monitoring |

|---|---|

| Data Management | Uses dimension reduction to manage thousands of sensor inputs |

| Signal Quality | Filters background noise and removes redundant data points |

| Reliability | Increases anomaly diagnosis accuracy to approximately 89% |

| Efficiency | Drastically reduces false alarms for improved operational focus |

| Core Function | Extracts critical variables to isolate essential performance patterns |

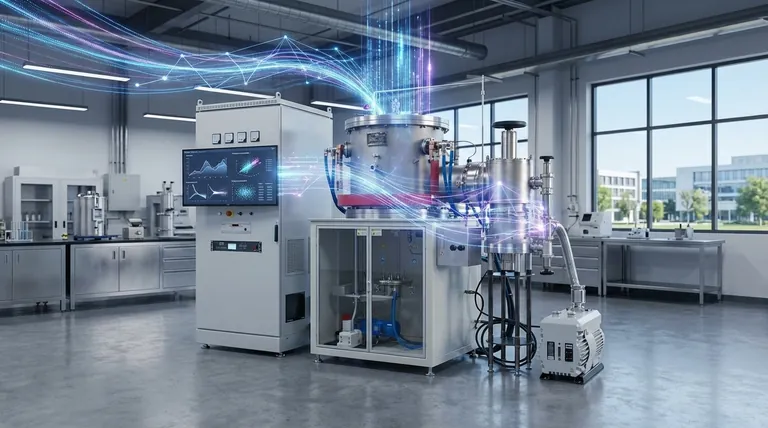

Optimize Your Thermal Processing with KINTEK Expertise

Don't let data noise compromise your operational efficiency. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temperature furnaces. Our systems are fully customizable to meet your unique research and production needs, ensuring precise control and reliable results.

Ready to elevate your lab's performance? Contact us today to discover how our advanced furnace solutions and technical support can streamline your processes and enhance diagnostic accuracy.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How can manufacturers select the appropriate sintering furnace for their needs? Optimize Your Production with the Right Equipment

- What are the applications of furnace brazing in the energy and power generation sector? Achieve Superior Joint Integrity for Critical Components

- How does a vacuum oven contribute to processing solid residues in biomass fractionation? Ensure Sample Integrity

- Why is a high-vacuum sintering furnace essential for copper-iron composites? Achieve Pure, High-Density Results

- What are the size ranges and common applications of crucible furnaces? Find Your Perfect Fit for Small-Batch Melting

- How is furnace brazing used in research and development? Unlock Precision Joining for Material Innovation

- What are the main types of vacuum furnaces classified by use? Find the Perfect Fit for Your Thermal Process

- Why is vacuum furnace brazing popular? Achieve Strong, Clean Joints for High-Performance Applications