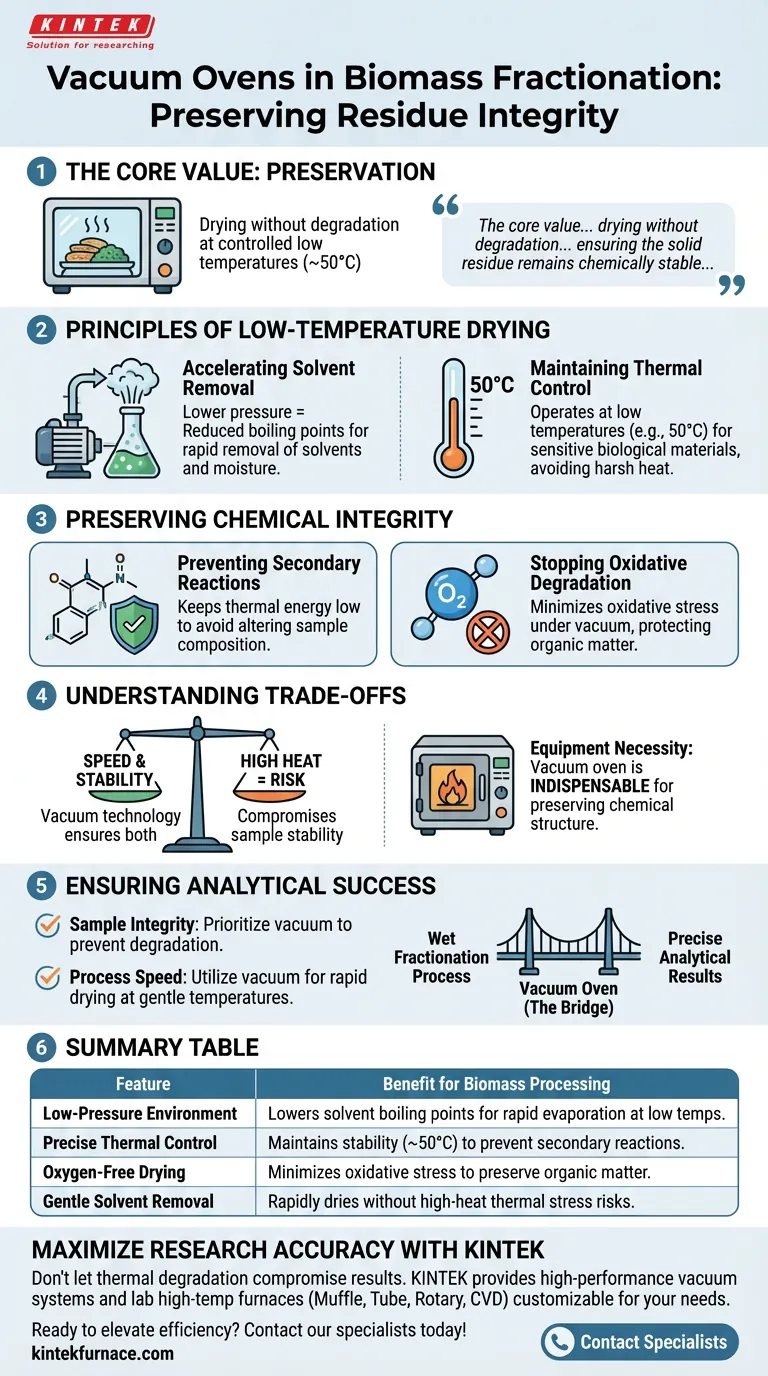

A vacuum oven serves a critical preservation role in the processing of solid residues during biomass fractionation. It is primarily utilized to dry solid filter cakes at controlled, low temperatures—typically around 50°C. By operating under reduced pressure, the oven facilitates the rapid removal of residual solvents and moisture without subjecting the material to destructive thermal stress.

The core value of a vacuum oven is not just drying, but drying without degradation. It allows you to remove moisture and solvents efficiently while preventing secondary reactions and oxidative damage, ensuring the solid residue remains chemically stable for accurate downstream analysis.

The Principles of Low-Temperature Drying

Accelerating Solvent Removal

The vacuum environment fundamentally alters the thermodynamics of evaporation. By lowering the pressure, the boiling points of solvents and water are significantly reduced.

This allows for the rapid removal of moisture and residual solvents from solid filter cakes. You achieve drying speeds comparable to high-heat methods without actually applying high heat.

Maintaining Thermal Control

Because the vacuum handles the heavy lifting of evaporation, the oven operates at much lower temperatures, such as 50°C.

This low-temperature operation is essential for processing sensitive biological materials. It avoids the harsh conditions typical of standard convection ovens.

Preserving Chemical Integrity

Preventing Secondary Reactions

Biomass components are chemically complex and often reactive. High temperatures can trigger undesirable secondary reactions that alter the composition of the sample.

The vacuum oven prevents these reactions by keeping the thermal energy input below the threshold that triggers chemical changes. This ensures the residue you analyze represents the actual outcome of the fractionation, not a byproduct of the drying process.

Stopping Oxidative Degradation

Heat combined with oxygen is a recipe for degrading organic matter.

By drying under vacuum, you minimize the sample's exposure to oxidative stress. This protects the biomass components from oxidative degradation, preserving their structural fidelity.

Understanding the Trade-offs

Speed vs. Stability

In many processing scenarios, speed is achieved by cranking up the heat. However, in biomass fractionation, this approach compromises the sample.

The trade-off here is that to ensure sample stability, you must rely on vacuum technology rather than simple thermal energy. You cannot simply increase the temperature to dry faster without risking the integrity of the data.

Equipment Necessity

Achieving this level of preservation requires specific hardware. Simple air drying is too slow and may allow biological degradation, while standard ovens are too aggressive.

Therefore, the vacuum oven is an indispensable, non-negotiable tool for any process where the chemical structure of the solid residue must be preserved for analysis.

Ensuring Analytical Success

To maximize the quality of your biomass data, consider the following recommendations:

- If your primary focus is Sample Integrity: Prioritize the vacuum oven to prevent oxidative degradation and secondary reactions during the drying phase.

- If your primary focus is Process Speed: Utilize the vacuum setting to lower solvent boiling points, allowing for rapid drying even at gentle temperatures like 50°C.

The vacuum oven is the bridge between the wet fractionation process and precise analytical results, ensuring what you measure is exactly what you produced.

Summary Table:

| Feature | Benefit for Biomass Processing |

|---|---|

| Low-Pressure Environment | Lowers solvent boiling points for rapid evaporation at low temperatures. |

| Precise Thermal Control | Maintains stability (approx. 50°C) to prevent secondary chemical reactions. |

| Oxygen-Free Drying | Minimizes oxidative stress to preserve organic matter and structural fidelity. |

| Gentle Solvent Removal | Rapidly dries solid filter cakes without the risks of high-heat thermal stress. |

Maximize Your Biomass Research Accuracy with KINTEK

Don’t let thermal degradation compromise your analytical results. At KINTEK, we understand that preserving the chemical integrity of your samples is paramount. Backed by expert R&D and world-class manufacturing, we provide high-performance vacuum systems and lab high-temp furnaces—including Muffle, Tube, Rotary, and CVD systems—all customizable to meet your specific fractionation requirements.

Ready to elevate your lab’s efficiency and data precision?

Contact our specialists today to find your custom solution!

Visual Guide

References

- Multi-step pre-treatment of rice husk for fractionation of components including silica. DOI: 10.3389/fchem.2025.1538797

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the technical advantages of using a high-vacuum high-temperature sintering furnace for stainless steel?

- What critical function does argon gas serve in sintering Ti2AlN ceramics? Ensure Phase Purity and Prevent Oxidation

- What role does a vacuum system play in Vanadium-Nitrogen alloy preparation? Boost Chemical Efficiency and Yield

- Why is the use of a vacuum oven essential during graphite anode preparation? Ensure Battery Safety and Longevity

- Why is a high-precision vacuum oven necessary for RGO/PI composite films? Ensure Defect-Free Graded Heat Treatment

- What is the role of insulation materials in a vacuum furnace? Boost Efficiency and Precision in High-Temp Processing

- Why is the vacuum-assisted impregnation process necessary for UHTCMCs? Achieve Superior Composite Density

- What are the main functions of an annealing furnace? Achieve Precise Material Control and Enhanced Performance