High-vacuum high-temperature sintering furnaces are the definitive solution for processing stainless steel composites where material purity and structural density are paramount. By generating temperatures up to 1400 °C in an environment with an extremely low oxygen background, these systems directly address the chemical vulnerabilities of stainless steel at elevated heat.

The core technical advantage lies in the synergy between a contaminant-free vacuum and liquid phase mechanics. This environment prevents the degradation of the stainless steel matrix while utilizing capillary forces to achieve near-perfect density and exceptional interfacial bonding strength.

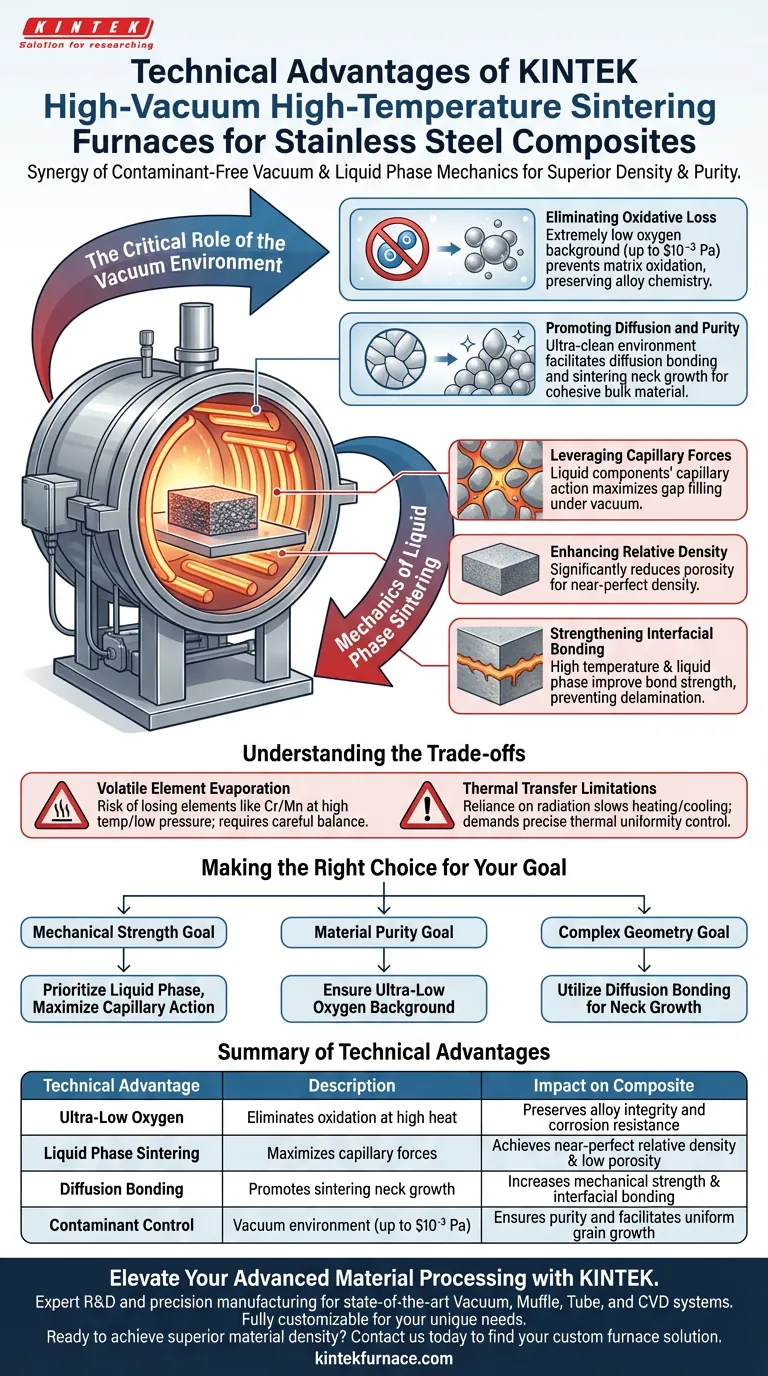

The Critical Role of the Vacuum Environment

Eliminating Oxidative Loss

The primary challenge in sintering stainless steel is its susceptibility to oxidation at high temperatures. A high-vacuum furnace creates an extremely low oxygen background, which is critical for preserving the chemical integrity of the material. This effectively prevents the oxidative loss of the stainless steel matrix, ensuring the final composite retains its intended alloy composition and mechanical properties.

Promoting Diffusion and Purity

Beyond simple oxidation prevention, the vacuum environment actively assists in the microstructural evolution of the material. By maintaining an ultra-clean environment (potentially reaching $10^{-3}$ Pa), the furnace ensures that contaminants do not impede grain growth. This facilitates diffusion bonding and the growth of sintering necks between particles, which are necessary for creating a cohesive bulk material.

Mechanics of Liquid Phase Sintering

Leveraging Capillary Forces

When sintering composite materials, achieving high density is often difficult due to the complex mix of particles. These furnaces facilitate liquid phase sintering, where specific components melt while others remain solid. Under vacuum, the capillary forces of these liquid components are maximized, allowing them to effectively fill inter-particle gaps.

Enhancing Relative Density

The result of this capillary action is a significant reduction in porosity. By filling voids that solid-state sintering might leave behind, the process drastically enhances the relative density of the composite. This leads to a final product that is less porous and mechanically superior to those processed in standard atmospheres.

Strengthening Interfacial Bonding

Density alone does not guarantee strength; the bond between the matrix and the reinforcement is vital. The combination of high temperature (up to 1400 °C) and liquid phase filling improves the interfacial bonding strength. This ensures that stress is effectively transferred throughout the composite, preventing delamination or brittle failure under load.

Understanding the Trade-offs

Volatile Element Evaporation

While high vacuum is excellent for preventing oxidation, it introduces a risk regarding alloy chemistry. At high temperatures and low pressures, volatile elements (such as Chromium or Manganese often found in stainless steel) can have high vapor pressures. Operators must carefully balance vacuum levels and temperature to prevent the selective evaporation of these critical alloying elements, which could alter the steel's corrosion resistance.

Thermal Transfer Limitations

In a vacuum, heat transfer relies entirely on radiation rather than convection. This can lead to slower heating and cooling cycles compared to atmosphere furnaces. Precise control of heating elements and chamber design is required to ensure thermal uniformity across the workload, preventing uneven sintering or thermal shock.

Making the Right Choice for Your Goal

Selecting the correct sintering parameters depends heavily on the specific performance metrics you need to maximize for your stainless steel composite.

- If your primary focus is mechanical strength: Prioritize liquid phase sintering parameters to maximize capillary action, ensuring high relative density and robust interfacial bonding.

- If your primary focus is material purity: Ensure the vacuum system can maintain an ultra-low oxygen background to prevent matrix oxidation and surface contamination.

- If your primary focus is complex geometry: Utilize the diffusion bonding capabilities to promote sintering neck growth, which stabilizes porous or intricate structures.

By controlling the atmosphere and leveraging liquid phase dynamics, you transform a loose powder mixture into a high-performance, oxidation-free composite.

Summary Table:

| Technical Advantage | Description | Impact on Composite |

|---|---|---|

| Ultra-Low Oxygen | Eliminates oxidation at high heat | Preserves alloy integrity and corrosion resistance |

| Liquid Phase Sintering | Maximizes capillary forces to fill gaps | Achieves near-perfect relative density and low porosity |

| Diffusion Bonding | Promotes sintering neck growth | Increases mechanical strength and interfacial bonding |

| Contaminant Control | Vacuum environment (up to $10^{-3}$ Pa) | Ensures purity and facilitates uniform grain growth |

Elevate Your Advanced Material Processing with KINTEK

Backed by expert R&D and precision manufacturing, KINTEK provides state-of-the-art Vacuum, Muffle, Tube, and CVD systems designed for the most demanding sintering applications. Our high-vacuum furnaces are fully customizable to meet your unique needs for temperature uniformity, atmosphere control, and chemical purity. Whether you are developing stainless steel composites or advanced ceramics, our team is ready to optimize your results.

Ready to achieve superior material density? Contact us today to find your custom furnace solution.

Visual Guide

References

- Kalyanamanohar Veeramallu, Alluru Gopala Krishna. Enhanced Wear and Corrosion Performance of Stainless Steel 316L with Addition of Different Weight Percentages of GNP. DOI: 10.62753/ctp.2024.04.1.1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the advantages of using a vacuum drying oven for ceramic powders? Preserve Purity and Sinterability

- What conditions does a vacuum furnace provide for Nb3Sn repair? Precision Heat and High Vacuum for Superconductors

- Why must a vacuum heat treatment furnace be used for MOF-CIGCs? Prevent Oxidation & Ensure Perfect Glass Encapsulation

- What is unique about the heating mechanism of a Spark Plasma Sintering (SPS) furnace when preparing nanostructured h-BN ceramics? Achieve Ultra-Fast Densification and Suppress Grain Growth

- How does the design of a large-scale laboratory vacuum unit prevent secondary contamination? Isolation via Quartz Screens

- Why is a vacuum furnace used for long-term heat exposure experiments on Nb-22.5Cr-5Si alloys? Ensure Data Integrity

- What is sinter used for in blast furnace? The Engineered Feed for Peak Efficiency

- Why is a vacuum heat treatment furnace necessary for the gas nitriding of AISI 5140 steel? Achieve Precision Hardening