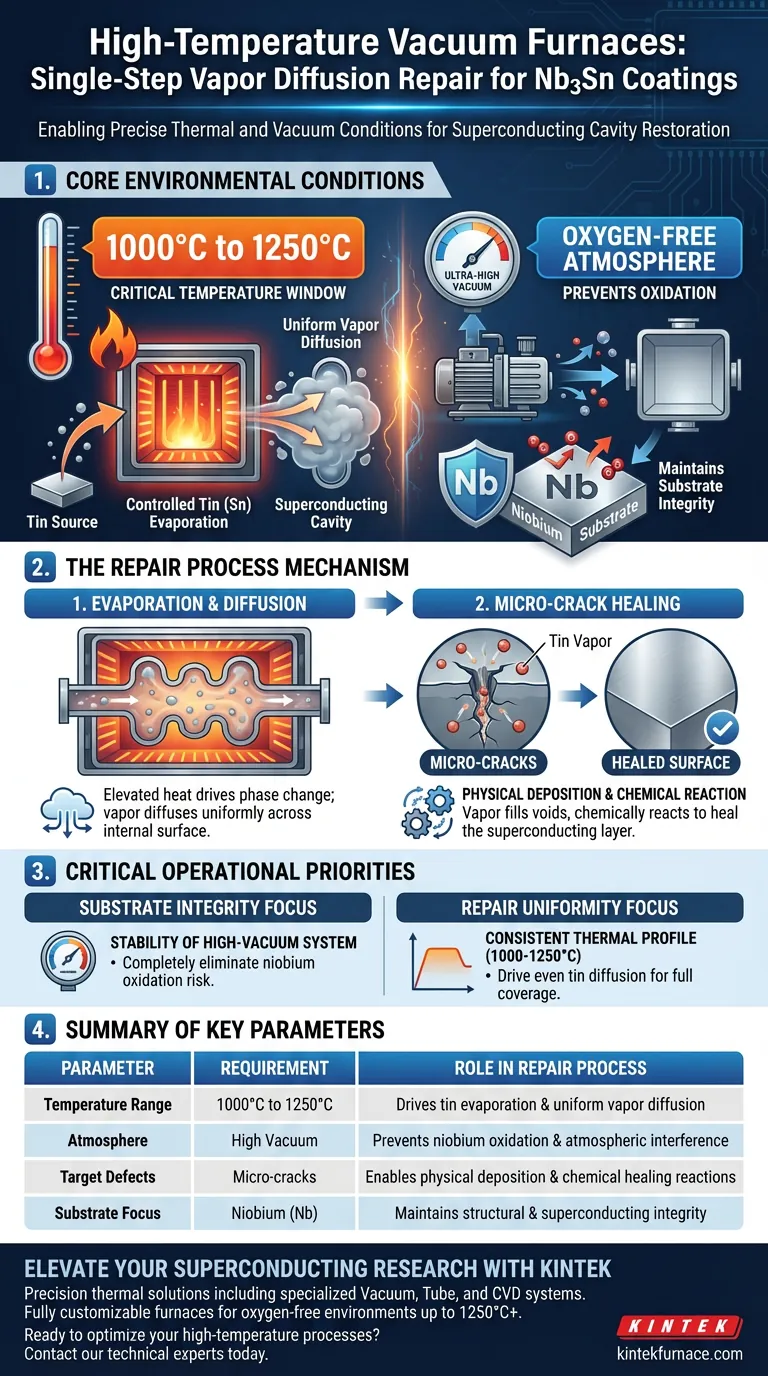

To enable the single-step vapor diffusion repair of Nb3Sn coatings, a high-temperature vacuum furnace must provide a precise thermal environment between 1000°C and 1250°C alongside a high-vacuum atmosphere. This specific combination allows for the controlled evaporation of the tin (Sn) source and its uniform diffusion across the internal surface of the superconducting cavity. Simultaneously, the vacuum prevents the oxidation of the niobium substrate, enabling the physical deposition and chemical reactions required to heal micro-cracks.

The success of this repair process hinges on the furnace's ability to maintain an oxygen-free environment while sustaining temperatures high enough to turn solid tin into a reactive vapor that penetrates and heals microscopic surface defects.

Thermal Control and Diffusion Dynamics

The Critical Temperature Window

The furnace operates within a strict temperature range of 1000°C to 1250°C.

This elevated heat is the primary driver for the phase change of the tin source. At these temperatures, the tin evaporates effectively, creating the necessary vapor pressure for the repair process.

Achieving Uniform Coverage

Precise temperature control ensures that the tin vapor does not just evaporate, but diffuses uniformly.

This uniformity is essential for covering the entire internal surface of the superconducting cavity, ensuring no area is left untreated.

The Role of the Vacuum Environment

Preventing Substrate Damage

The high-vacuum environment is not merely for cleanliness; it is a chemical necessity.

At elevated temperatures, niobium is highly reactive to oxygen. The vacuum prevents oxidation of the niobium substrate, ensuring the base material maintains its structural and superconducting integrity during the intense heating cycle.

Facilitating Micro-Crack Healing

The vacuum environment facilitates a dual mechanism of physical deposition and chemical reaction.

By removing atmospheric interference, the tin vapor can penetrate micro-cracks within the coating. It physically fills these voids and chemically reacts with the existing structure to "heal" the superconducting layer.

Critical Operational Requirements

Balancing Heat and Pressure

The process relies on the synergy between heat and vacuum.

If the temperature drops below the 1000°C threshold, the tin may fail to evaporate or diffuse sufficiently to repair defects. Conversely, if the vacuum integrity is compromised, the high heat will destroy the niobium cavity through oxidation rather than repairing it.

The Mechanism of Repair

The furnace conditions are designed to target micro-cracks specifically.

The environment promotes the formation of new Nb3Sn material at these defect sites, restoring the continuity of the superconducting surface.

Optimizing Process Parameters

To ensure the effective repair of superconducting cavities, consider these operational priorities:

- If your primary focus is Substrate Integrity: Prioritize the stability of the high-vacuum system to completely eliminate the risk of niobium oxidation.

- If your primary focus is Repair Uniformity: Ensure the thermal profile allows for consistent heating between 1000°C and 1250°C to drive even tin diffusion.

By strictly maintaining these environmental parameters, you transform a potentially destructive high-heat process into a precise restorative treatment for superconducting components.

Summary Table:

| Parameter | Requirement | Role in Repair Process |

|---|---|---|

| Temperature Range | 1000°C to 1250°C | Drives tin evaporation and uniform vapor diffusion |

| Atmosphere | High Vacuum | Prevents niobium oxidation and atmospheric interference |

| Target Defects | Micro-cracks | Enables physical deposition and chemical healing reactions |

| Substrate Focus | Niobium (Nb) | Maintains structural and superconducting integrity |

Elevate Your Superconducting Research with KINTEK

Precision is non-negotiable when dealing with high-temperature vapor diffusion and Nb3Sn repair. KINTEK provides industry-leading thermal solutions, including specialized Vacuum, Tube, and CVD systems designed to maintain the rigorous oxygen-free environments and stable thermal profiles (up to 1250°C+) required for advanced materials science.

Backed by expert R&D and manufacturing, our furnaces are fully customizable to meet your unique laboratory or industrial needs. Whether you are healing micro-cracks in superconducting cavities or developing next-generation coatings, KINTEK delivers the reliability you need to succeed.

Ready to optimize your high-temperature processes? Contact our technical experts today to find the perfect furnace solution.

Visual Guide

References

- Eric Viklund, Grigory Eremeev. Healing gradient degradation in Nb3Sn SRF cavities using a recoating method. DOI: 10.1063/5.0218739

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the purpose of using a high-vacuum system and annealing furnace for Mn–Ni–Fe–Si alloys? Unlock Data Accuracy

- How does a vacuum furnace prevent oxidation of the workpiece? Achieve Purity and Precision in High-Temp Processing

- What are the advantages of sintering furnaces? Achieve High-Quality, Dense Parts Efficiently

- Why must silicon nitride mixed slurries undergo solvent removal in a high-vacuum oven? Ensure Peak Ceramic Integrity

- Why is a high-pressure reactor core equipment for hydrothermal carbonization? Unlock Superior Carbon Skeletons

- What is the purpose of an annealing furnace in the mechanical industry? Boost Metal Performance and Efficiency

- What are the specifications for resistance heating in vacuum graphitizing furnaces? Achieve Superior Graphitization for Large-Scale Production

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas