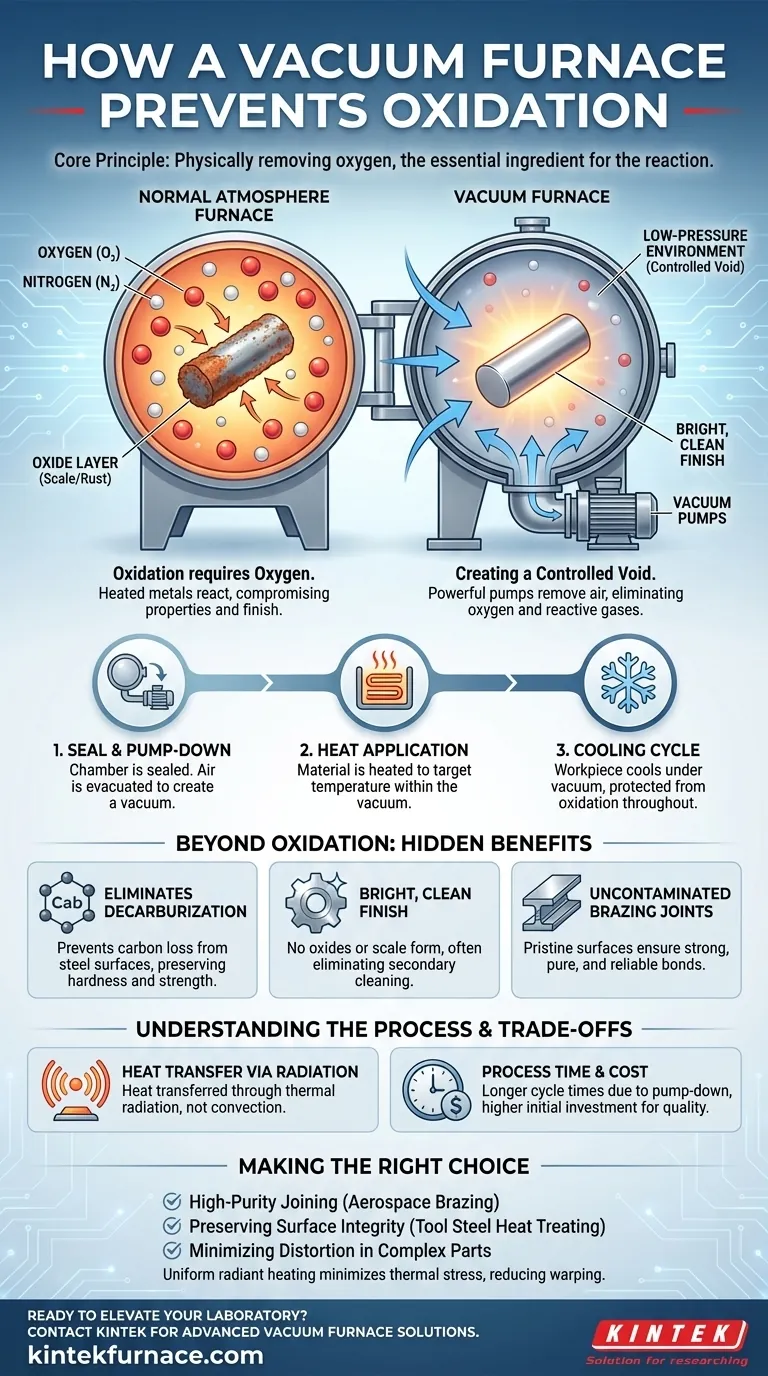

At its core, a vacuum furnace prevents oxidation by physically removing the key ingredient required for the reaction: oxygen. By using powerful pumps to evacuate the sealed heating chamber, the furnace creates a low-pressure environment where there are too few oxygen molecules to react with the hot metal workpiece. This ensures that materials can be heated to extreme temperatures without forming the undesirable oxide layers that occur in a normal atmosphere.

The fundamental advantage of a vacuum furnace is not just the prevention of oxidation, but the creation of a chemically inert environment. This control over the atmosphere allows for cleaner surfaces, stronger joints, and less material deformation than conventional heating methods.

The Fundamental Principle: Removing the Reactant

The strategy behind a vacuum furnace is elegantly simple. Instead of fighting an unwanted chemical reaction, it removes one of its essential components, making the reaction impossible.

Oxidation Requires Oxygen

When heated, most metals eagerly react with atmospheric oxygen. This chemical process, oxidation, forms a layer of metal oxide on the surface, which can appear as discoloration, scale, or rust. This layer can compromise the material's properties, dimensions, and finish.

Creating a Controlled Void

A vacuum furnace begins its cycle by sealing the chamber and using a system of vacuum pumps to remove the air. This process, known as pump-down, eliminates the vast majority of oxygen, nitrogen, water vapor, and other reactive gases.

The result is a low-pressure environment where the workpiece is isolated from any substance that could contaminate its surface during heating.

The Process in Action

The typical cycle involves loading the workpiece, pumping the chamber down to a specific vacuum level, and only then applying heat. The material is heated to the target temperature, held for the required time, and then cooled—all within the controlled vacuum. This ensures the part is protected from oxidation throughout the entire thermal cycle.

Beyond Oxidation: The Hidden Benefits of a Vacuum

Preventing oxidation is the primary goal, but the vacuum environment provides several other critical manufacturing advantages. These secondary benefits are often the reason vacuum processing is specified for high-performance components.

Eliminating Decarburization

For carbon-based steels, a hot, oxygen-rich atmosphere can pull carbon atoms from the surface of the metal. This phenomenon, known as decarburization, creates a soft, weakened outer layer. A vacuum environment completely prevents this, ensuring the material's surface hardness and fatigue life are preserved.

Achieving a Bright, Clean Finish

Because no oxides or scale form on the surface, parts emerge from a vacuum furnace with a bright, clean finish. This often eliminates the need for secondary cleaning processes like sandblasting or acid pickling, saving time and reducing production costs.

Ensuring Uncontaminated Joints for Brazing

In vacuum brazing, the absence of oxygen is critical. Surface oxides prevent the filler metal from properly wetting and flowing into the joint, resulting in a weak or incomplete bond. The pristine surfaces maintained in a vacuum allow for exceptionally strong, pure, and reliable brazed joints.

Understanding the Trade-offs and Operating Principles

While powerful, the vacuum method has unique characteristics that influence its application and results. Understanding these is key to leveraging its full potential.

Heat Transfer via Radiation

In a normal furnace, heat is transferred through convection (movement of hot air) and conduction. In the near-void of a vacuum, convection is negligible. Heat is transferred almost exclusively through thermal radiation.

The Impact on Uniformity and Distortion

Radiant heating is more uniform and less aggressive than convective heating. This results in a smaller temperature difference between the surface and the core of the workpiece as it heats and cools. This gentle, even heating minimizes thermal stress, leading to significantly less distortion and warping, especially in complex or delicate parts.

Process Time and Cost

The primary trade-off is cycle time. The need to pump down the chamber adds time to the beginning of every process. For this reason, vacuum furnaces represent a higher initial investment and can have longer cycle times than atmospheric furnaces, making them best suited for applications where the final quality is paramount.

Making the Right Choice for Your Application

Choosing to use a vacuum furnace depends entirely on the required outcome for your material and component.

- If your primary focus is high-purity joining (e.g., aerospace brazing): The vacuum's ability to create an oxide-free surface is non-negotiable for achieving maximum joint strength and reliability.

- If your primary focus is preserving surface integrity (e.g., heat treating tool steel): The vacuum prevents both oxidation and decarburization, ensuring the material's designed hardness and finish are maintained without post-processing.

- If your primary focus is minimizing distortion in complex parts: The uniform radiant heating inherent to a vacuum process significantly reduces the thermal stress that causes warping.

Ultimately, a vacuum furnace provides an unparalleled level of environmental control, transforming high-temperature processing from a potential source of defects into a precision manufacturing step.

Summary Table:

| Aspect | Description |

|---|---|

| Oxidation Prevention | Removes oxygen via vacuum, eliminating oxide formation on workpieces. |

| Key Benefits | Prevents decarburization, ensures bright finish, and minimizes distortion. |

| Heat Transfer | Uses thermal radiation for uniform heating, reducing thermal stress. |

| Ideal Applications | High-purity brazing, surface integrity preservation, and complex part processing. |

Ready to elevate your laboratory's capabilities with advanced vacuum furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization to meet unique experimental requirements. Whether you're in aerospace, materials science, or tool steel heat treatment, our vacuum furnaces deliver unparalleled purity, strength, and precision. Contact us today to discuss how we can optimize your processes and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion