In the mechanical industry, an annealing furnace is a critical tool for heat treatment. Its primary purpose is to alter a metal's microstructure to achieve specific results, most notably to soften the material, increase its ductility, and relieve internal stresses that accumulate during manufacturing processes like casting, forging, and welding. This controlled heating and cooling cycle makes the material more predictable and easier to work with.

The core function of annealing is to reverse the undesirable effects of manufacturing. Processes that shape or join metal often leave it hard, brittle, and full of internal stress; annealing acts as a "reset," creating a softer, more stable, and uniform material ready for subsequent machining or its final application.

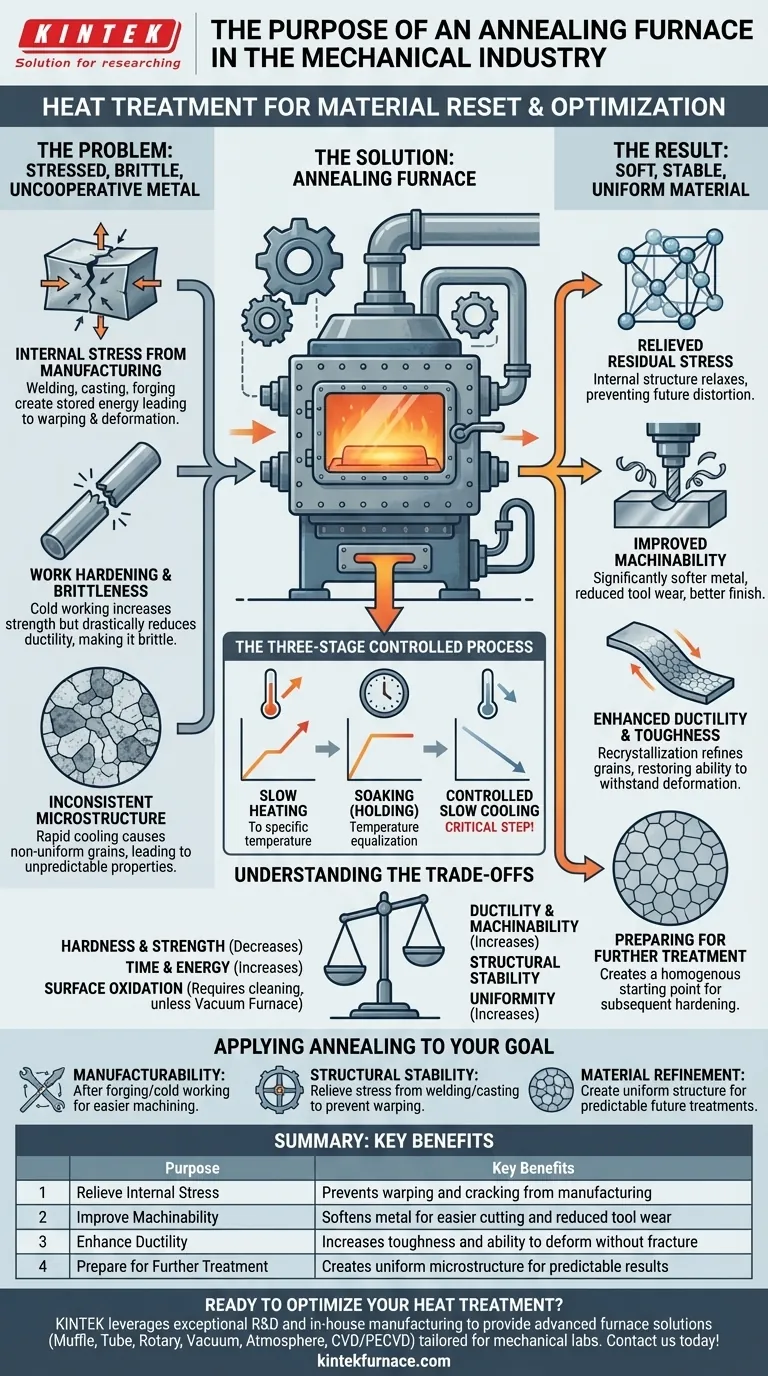

The Core Problem: Why Annealing is Necessary

Before a metal part is annealed, it often exists in a stressed and uncooperative state. Several common manufacturing processes create this condition, making annealing a necessary intermediate step.

Internal Stress from Manufacturing

Processes like welding, casting, or heavy forging introduce significant internal stresses into a material's atomic structure. If left unaddressed, this stored energy can lead to warping, deformation, or even spontaneous cracking over time.

Work Hardening and Brittleness

When metal is bent, rolled, or drawn at cold temperatures, it undergoes work hardening. While this increases its strength and hardness, it also drastically reduces its ductility, making it brittle and prone to fracture if further forming is attempted.

Inconsistent Microstructure

Rapid cooling, such as in casting, can create a non-uniform and coarse grain structure within the metal. This inconsistency can lead to unpredictable mechanical properties and weak points throughout the workpiece.

How an Annealing Furnace Solves These Problems

An annealing furnace uses a precise thermal cycle to systematically undo the problems of stress, hardness, and inconsistency. The process is fundamentally about control.

The Three-Stage Process

Annealing consists of three key stages. First, the material is slowly heated to a specific temperature. Second, it is held (or "soaked") at that temperature to allow the entire part to equalize. Finally, it is cooled at a very slow, controlled rate, which is the most critical step for achieving the desired properties.

Relieving Residual Stress

The slow cooling phase allows the metal's internal crystal lattice to relax and reform into a lower-energy, more stable arrangement. This effectively eliminates the residual stresses locked in from previous operations, preventing future distortion.

Improving Machinability

By reducing the material's overall hardness, annealing makes it significantly softer. This directly improves machinability, allowing for easier cutting, reduced tool wear, faster machining speeds, and a better surface finish.

Enhancing Ductility and Toughness

The heating and soaking stages cause a phenomenon called recrystallization, where new, strain-free grains form and refine the material's microstructure. This refined grain structure is what restores ductility and toughness, making the metal capable of withstanding plastic deformation without fracturing.

Preparing for Further Treatment

For parts that require a final hardening process like quenching, annealing is used to create a uniform, fine-grained microstructure. This provides a predictable and homogenous starting point, ensuring the final heat treatment responds evenly across the entire workpiece.

Understanding the Trade-offs

While highly effective, annealing is not without its compromises. Understanding these trade-offs is key to using the process correctly.

The Cost of Hardness and Strength

The primary outcome of annealing is softening. This means there is a direct trade-off between the improved ductility and machinability you gain and the hardness and tensile strength you lose. For this reason, annealing is often an intermediate step, not the final one.

Time and Energy Consumption

The annealing cycle, particularly the slow cooling stage, is time-intensive and requires significant thermal energy. This adds both time and cost to the overall manufacturing process.

Surface Oxidation and Scale

When heated in the presence of oxygen, most metals will form an oxide layer, or "scale," on the surface. This often requires a secondary cleaning process like pickling or sandblasting. This can be avoided by using a vacuum annealing furnace, which performs the cycle in an oxygen-free environment.

Applying Annealing to Your Goal

Your decision to use annealing should be driven by the specific properties you need to achieve for your component.

- If your primary focus is manufacturability: Use annealing after forging or cold working to soften the material, making it easier to machine, form, or draw.

- If your primary focus is structural stability: Use annealing to relieve internal stresses from welding or casting to prevent long-term warping or stress-corrosion cracking.

- If your primary focus is material property refinement: Use annealing to create a uniform and refined grain structure for predictable results from subsequent heat treatments like quenching and tempering.

Ultimately, mastering the annealing process gives you precise control over a material's fundamental mechanical properties.

Summary Table:

| Purpose | Key Benefits |

|---|---|

| Relieve Internal Stress | Prevents warping and cracking from manufacturing |

| Improve Machinability | Softens metal for easier cutting and reduced tool wear |

| Enhance Ductility | Increases toughness and ability to deform without fracture |

| Prepare for Further Treatment | Creates uniform microstructure for predictable results |

Ready to optimize your metal heat treatment process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for mechanical industry labs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our annealing furnaces can enhance your material performance and efficiency!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality