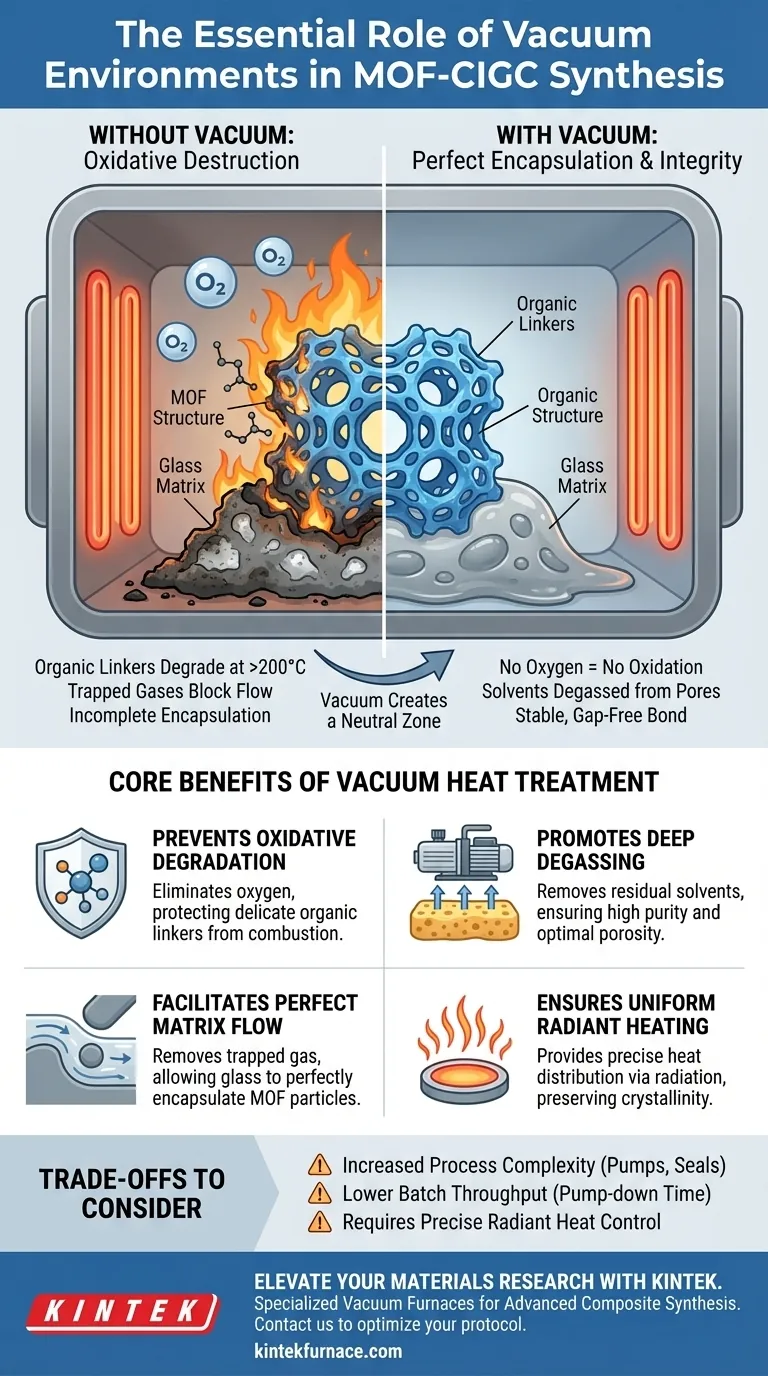

A heat treatment furnace equipped with a vacuum environment is strictly required to preserve the chemical integrity of Metal-Organic Frameworks (MOFs) during synthesis.

Specifically, it prevents the oxidative degradation of the MOF’s organic linkers which occurs at elevated temperatures (around 200 °C). Simultaneously, the vacuum pressure promotes the removal of trapped solvents and ensures the glass matrix can soften and flow to perfectly encapsulate the MOF particles without interference.

Core Insight: Successful MOF-CIGC synthesis is a race against thermal decomposition. The vacuum furnace creates a "neutral zone" that allows the glass matrix to melt and bond physically without triggering the chemical destruction of the delicate MOF structure.

Protecting the Framework Integrity

The primary challenge in synthesizing MOF-CIGCs (Metal-Organic Framework Crystal-Glass Composites) is that MOFs are thermally sensitive.

Preventing Oxidative Degradation

MOFs contain organic ligands (carbon-based linkers) that bind metal nodes together.

In the presence of oxygen, these organic components will burn or degrade rapidly when temperatures approach or exceed 200 °C.

The vacuum environment removes oxygen from the chamber, effectively eliminating the possibility of combustion or oxidation, ensuring the MOF structure remains intact during the heating phase.

Stabilizing Thermal Tolerance

By removing reactive atmospheric gases, the vacuum furnace extends the effective thermal working range of the MOF.

This allows the composite to reach the temperatures necessary for the glass matrix to transition without sacrificing the porosity or crystallinity of the ZIF-8 (or similar MOF) filler.

Optimizing the Composite Structure

Beyond protection, the vacuum environment plays an active mechanical role in forming a high-quality composite.

Removing Residual Solvents

MOFs are highly porous materials that often retain solvents from their initial synthesis.

Heating under vacuum acts as a powerful degassing mechanism, pulling these residual solvent molecules out of the framework's pores.

This "cleaning" of the pores is essential to ensure the final material retains its desired adsorptive properties.

Facilitating Matrix Flow and Bonding

For the composite to be mechanically sound, the glass matrix must soften and flow around the MOF particles.

The vacuum environment removes gas pockets that could otherwise become trapped between the glass and the MOF.

This allows the glass to achieve perfect encapsulation, creating a stable interfacial bond between the two distinct phases.

Understanding the Trade-offs

While vacuum heat treatment is chemically necessary for this application, it introduces specific operational constraints compared to standard atmospheric ovens.

Increased Process Complexity

Vacuum furnaces require significantly more complex infrastructure, including pumps, seals, and pressure monitoring systems.

Throughput Limitations

The process is generally a batch operation.

The time required to pump the chamber down to the required vacuum level adds to the total cycle time, potentially limiting manufacturing throughput compared to continuous-flow atmospheric heating.

Thermal Transfer Differences

In a vacuum, heat transfer occurs primarily through radiation rather than convection.

This requires precise control systems to ensure uniformity, as shadowing effects can cause uneven heating if the furnace is not loaded correctly.

Making the Right Choice for Your Goal

When setting up your synthesis protocol for MOF-CIGCs, consider the following prioritization:

- If your primary focus is Material Purity: Ensure your vacuum system is capable of deep degassing to fully evacuate solvent residues from the MOF pores before the glass matrix creates a seal.

- If your primary focus is Structural Stability: Prioritize the "soak time" at the target temperature under vacuum to allow the glass matrix sufficient time to flow and wet the MOF surface completely.

- If your primary focus is Equipment Longevity: Recognize that while vacuum prevents oxidation of the sample, it also prevents oxidation of furnace heating elements, generally extending the service life of the equipment.

Ultimately, the vacuum environment is not just a protective measure; it is a manufacturing tool that physically enables the coexistence of delicate crystals and molten glass.

Summary Table:

| Feature | Role in MOF-CIGC Synthesis | Benefit |

|---|---|---|

| Oxidation Prevention | Eliminates oxygen from the heating chamber | Prevents organic linkers from burning at >200°C |

| Degassing | Removes trapped solvent from porous MOF structures | Ensures high purity and optimal adsorptive properties |

| Matrix Flow | Removes gas pockets during glass softening | Achieves perfect, gap-free encapsulation of particles |

| Radiant Heating | Provides uniform heat transfer in a vacuum | Protects framework crystallinity during glass transition |

Elevate Your Advanced Material Synthesis with KINTEK

Don’t let oxidative degradation compromise your MOF-CIGC research. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems designed to provide the precise atmospheric control and thermal uniformity your lab requires. Whether you need standard or fully customizable lab high-temp furnaces, our equipment ensures your delicate crystal-glass composites achieve perfect structural integrity.

Ready to optimize your synthesis protocol? Contact KINTEK today to find the ideal vacuum solution for your unique research needs.

Visual Guide

References

- Ashleigh M. Chester, Thomas D. Bennett. Loading and thermal behaviour of ZIF-8 metal–organic framework-inorganic glass composites. DOI: 10.1039/d4dt00894d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the primary considerations for using a graphite crucible and a resistance furnace? Al-Cu-Li Alloy Prep Guide

- Why is a Vacuum Oven utilized for the final drying of BC-Fe3O4 nanoparticles? Preserve Purity and Porosity

- What automation features are present in modern vacuum furnaces? Boost Precision and Efficiency in Your Lab

- What are the key material requirements for crucibles used in the vacuum distillation of aluminum-magnesium alloys? Ensure High-Purity Metal Separation

- Why is vacuum brazing particularly suitable for aerospace applications? Achieve Strong, Pure Joints for Critical Components

- How does a high vacuum furnace facilitate the annealing treatment of AlCoCrFeNi2.1? Mastering Phase Transformation

- Why is a vacuum drying oven necessary before the electrochemical testing of sodium-ion battery electrodes? Optimize SIBs

- What are the key components of a condensation system in a vacuum distillation furnace? Achieve Superior Metal Vapor Separation