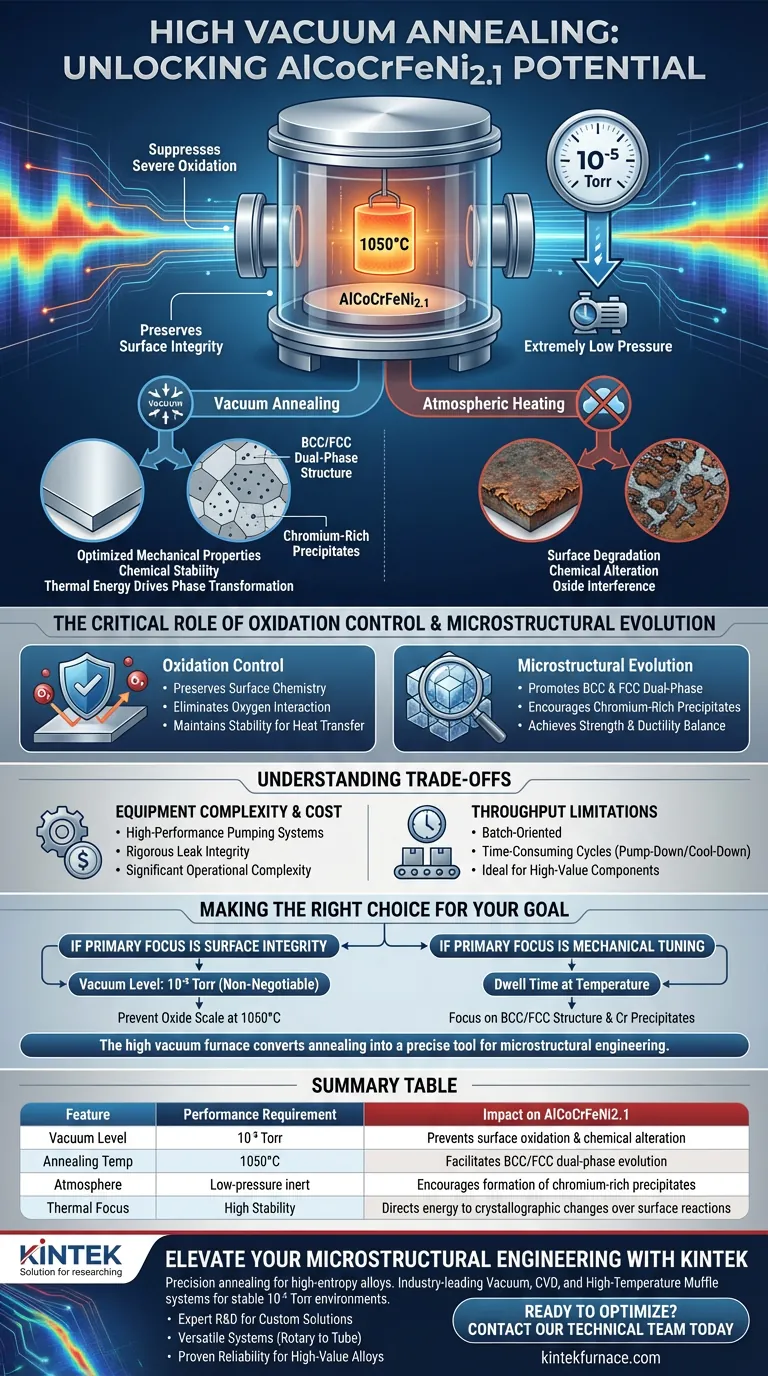

A high vacuum furnace facilitates the annealing of AlCoCrFeNi2.1 by maintaining an extremely low-pressure environment (approximately $10^{-5}$ Torr) during high-temperature treatment at 1050°C. This specific atmosphere effectively suppresses severe oxidation, allowing the alloy to undergo necessary phase transformations without surface degradation or chemical alteration.

By eliminating oxygen interaction during heat treatment, the furnace preserves the material's chemical stability. This allows thermal energy to drive the formation of chromium-rich precipitates and a dual-phase structure, which are the primary mechanisms for optimizing the alloy's mechanical properties.

The Critical Role of Oxidation Control

Preserving Surface Integrity

At annealing temperatures of 1050°C, most alloys are highly susceptible to rapid oxidation. The high vacuum furnace mitigates this risk by operating at pressures as low as $10^{-5}$ Torr.

Maintaining Chemical Stability

This low-pressure environment creates a barrier against atmospheric contaminants. By preventing severe oxidation, the furnace ensures that the surface chemistry of the AlCoCrFeNi2.1 coating or bulk material remains stable throughout the thermal cycle.

This stability is a prerequisite for successful annealing. Without it, the formation of surface oxides would interfere with the heat transfer and surface properties of the material.

Driving Microstructural Evolution

Promoting Phase Transformation

The core purpose of annealing this alloy is to manipulate its internal structure. The vacuum environment facilitates the evolution of a BCC (Body-Centered Cubic) and FCC (Face-Centered Cubic) dual-phase structure.

Because the material is not battling oxidation, the thermal energy is directed entirely toward these crystallographic changes. This dual-phase evolution is critical for achieving the desired balance of strength and ductility.

Encouraging Precipitation

The controlled thermal environment promotes the formation of chromium-rich precipitates.

These precipitates are essential for reinforcing the alloy matrix. The vacuum ensures these phases form uniformly without being compromised by interstitial oxygen or impurities.

Understanding the Trade-offs

Equipment Complexity and Cost

While vacuum annealing offers superior control, it introduces significant operational complexity compared to standard atmospheric furnaces. Achieving and maintaining $10^{-5}$ Torr requires high-performance pumping systems and rigorous leak integrity.

Throughput Limitations

The process is inherently batch-oriented and time-consuming due to the pump-down and cool-down cycles required to protect the material. This makes it excellent for high-value components but potentially less efficient for mass production of lower-grade parts.

Making the Right Choice for Your Goal

The use of a high vacuum furnace is not just about heating; it is about processing purity.

- If your primary focus is Surface Integrity: The vacuum level of $10^{-5}$ Torr is non-negotiable to prevent oxide scale formation at 1050°C.

- If your primary focus is Mechanical Tuning: Focus on the dwell time at temperature, as the vacuum environment creates the stability required to form the specific BCC/FCC dual-phase structure and chromium precipitates that define the alloy's strength.

The high vacuum furnace converts annealing from a simple heating process into a precise tool for microstructural engineering.

Summary Table:

| Feature | Performance Requirement | Impact on AlCoCrFeNi2.1 |

|---|---|---|

| Vacuum Level | 10⁻⁵ Torr | Prevents surface oxidation and chemical alteration |

| Annealing Temp | 1050°C | Facilitates BCC/FCC dual-phase evolution |

| Atmosphere | Low-pressure inert | Encourages formation of chromium-rich precipitates |

| Thermal Focus | High Stability | Directs energy to crystallographic changes over surface reactions |

Elevate Your Microstructural Engineering with KINTEK

Precision annealing of high-entropy alloys like AlCoCrFeNi2.1 requires the ultimate control over atmospheric purity. KINTEK provides industry-leading Vacuum, CVD, and High-Temperature Muffle systems designed to achieve stable 10⁻⁵ Torr environments, ensuring your coatings and bulk materials reach their optimal mechanical properties without surface degradation.

Why choose KINTEK?

- Expert R&D: Custom solutions for complex phase transformations.

- Versatile Systems: From Rotary to Tube furnaces, tailored to your batch requirements.

- Proven Reliability: Engineered for high-value alloy integrity.

Ready to optimize your heat treatment process? Contact our technical team today to find the perfect customizable furnace solution for your lab or production facility.

Visual Guide

References

- Chun‐Liang Chen, Fang-Yu Huang. Investigations of Oxide Dispersoids and Annealing on Characteristics of AlCoCrFeNi2.1 Coatings and Bulks Prepared by Mechanical Alloying. DOI: 10.3390/coatings14040442

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What roles do vacuum furnaces and pulse power supplies play in plasma nitriding? Enhance Steel Hardening & Uniformity

- How does the combined use of a centrifuge and a vacuum drying oven solve issues in H-Beta zeolite catalyst recovery?

- What are the key advantages of a vacuum environment in customized vacuum sintering furnaces? Achieve Purity, Strength, and Control

- What are the advantages of vacuum hardening? Achieve Superior Dimensional Accuracy and Cleanliness

- What are the functions of the vacuum chamber in the furnace? Ensure Purity and Precision in High-Temp Processes

- What are the advantages of using a vacuum annealing furnace? Achieve Clean, Oxidation-Free Heat Treatment

- Why is a high vacuum box sintering furnace required for B4C/Al composites? Unlock Peak Composite Performance

- What role does specialty insulation play in vacuum furnaces? Ensure Process Integrity and Efficiency