At its core, specialty insulation is the critical component that enables a vacuum furnace to function as a precisely controlled thermal environment. It is directly responsible for maintaining temperature uniformity within the furnace's hot zone, maximizing energy efficiency, and protecting the structural integrity of the furnace itself from extreme heat.

The role of insulation extends far beyond simple heat retention. It is the gatekeeper of process integrity, directly influencing everything from metallurgical quality and energy costs to operational uptime and the service life of the furnace.

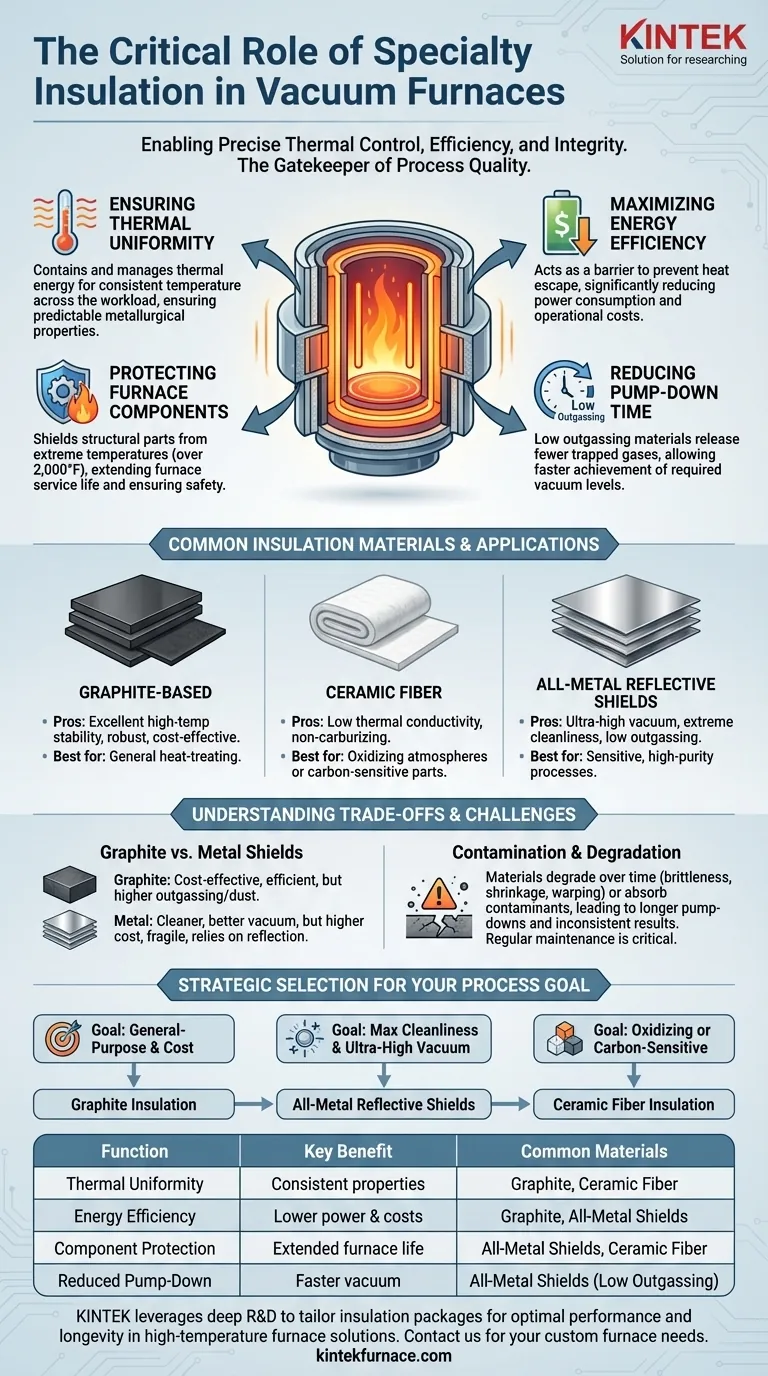

The Core Functions of Vacuum Furnace Insulation

A vacuum furnace's performance is fundamentally defined by its insulation system. Each function is critical to achieving a repeatable, high-quality thermal process.

Ensuring Thermal Uniformity

The primary job of the insulation is to contain and manage thermal energy within the hot zone—the area where parts are treated.

By minimizing heat loss, the insulation package ensures that the temperature is consistent and uniform across the entire workload. This uniformity is essential for achieving predictable and consistent metallurgical properties in the finished parts.

Maximizing Energy Efficiency

A well-designed insulation system acts as a barrier, preventing thermal energy from escaping to the furnace's water-cooled outer shell, or cold wall.

This containment dramatically reduces the power required to reach and maintain the target temperature. The result is lower energy consumption, reduced operational costs, and less stress on the heating elements.

Protecting Furnace Components

The extreme temperatures inside a hot zone, often exceeding 2,000°F (1,093°C), would quickly damage the furnace's structural components if left unshielded.

Insulation protects the vacuum chamber, power feedthroughs, and other critical systems from thermal degradation. This extends the service life of the furnace and ensures safe operation.

Reducing Pump-Down Time

A key, and often overlooked, function of high-quality insulation is its impact on vacuum performance. Specialty insulation materials are chosen for their low outgassing properties.

Outgassing is the release of trapped gases and moisture when a material is heated under vacuum. Materials with low outgassing release fewer molecules, allowing the vacuum pumps to reach the required vacuum level faster and more efficiently.

A Look at Common Insulation Materials

The choice of insulation material depends on the furnace's maximum temperature, the required vacuum level, and the specific process atmosphere.

Graphite-Based Insulation

Graphite, in the form of rigid boards, soft felt, or composite wafers, is the most common insulation material for vacuum furnaces.

It offers excellent high-temperature stability, is mechanically robust, and provides a good balance of performance and cost for a wide range of general heat-treating applications.

Ceramic Fiber Insulation

Ceramic fibers, such as alumina, are used in applications where carbon contamination from graphite is a concern or when operating in non-carburizing atmospheres.

These materials offer very low thermal conductivity but are typically more fragile and have lower maximum temperature ratings compared to graphite.

All-Metal Reflective Shields

Instead of absorbing heat, this insulation type uses multiple layers of reflective metal sheets, typically made of molybdenum or tungsten.

Each layer reflects radiant heat back into the hot zone. This design is ideal for achieving ultra-high vacuum levels and ensuring extreme cleanliness, as metals have exceptionally low outgassing properties compared to fiber or graphite.

Understanding the Trade-offs

No insulation type is perfect for every scenario. Understanding the compromises is key to selecting the right system and diagnosing potential issues.

Graphite vs. Metal Shields

Graphite insulation is generally more cost-effective and thermally efficient on a pure conductivity basis. However, it can be a source of carbon dust and has higher outgassing rates, which can be detrimental to sensitive materials.

All-metal shields provide a much cleaner environment and are superior for high-vacuum applications. Their primary downsides are higher initial cost, increased fragility, and potentially higher power consumption due to their reliance on radiation reflection.

The Risk of Contamination and Outgassing

Over time, any insulation can absorb moisture or become contaminated with process byproducts.

When heated, these contaminants will outgas, leading to longer pump-down times, process contamination, and inconsistent results. This is why proper furnace maintenance and periodic insulation bake-outs are critical.

Material Degradation Over Time

All insulation materials degrade. Graphite can become brittle, ceramic fibers can shrink and crack, and metal shields can warp or become embrittled.

This degradation reduces thermal efficiency, compromises temperature uniformity, and can ultimately lead to furnace failure if not monitored and addressed through scheduled replacement.

Making the Right Choice for Your Goal

Selecting the correct insulation is a strategic decision based on your specific process requirements.

- If your primary focus is general-purpose heat treating: Graphite insulation offers the best combination of durability, thermal performance, and cost-effectiveness.

- If your primary focus is maximum cleanliness or ultra-high vacuum: All-metal reflective shields are the superior choice, despite their higher cost and fragility.

- If your primary focus is processing in oxidizing atmospheres or for carbon-sensitive parts: Ceramic fiber insulation provides a necessary alternative to graphite.

Ultimately, the insulation system is the unseen foundation upon which every successful vacuum furnace cycle is built.

Summary Table:

| Function | Key Benefit | Common Materials |

|---|---|---|

| Thermal Uniformity | Consistent metallurgical properties | Graphite, Ceramic Fiber |

| Energy Efficiency | Lower power consumption & costs | Graphite, All-Metal Shields |

| Component Protection | Extended furnace service life | All-Metal Shields, Ceramic Fiber |

| Reduced Pump-Down Time | Faster vacuum achievement | All-Metal Shields (Low Outgassing) |

Struggling with temperature inconsistencies or high energy costs in your thermal processes? The right insulation system is the foundation of a reliable vacuum furnace. At KINTEK, we leverage our deep R&D and in-house manufacturing expertise to provide advanced high-temperature furnace solutions—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong customization capabilities allow us to tailor the insulation package and entire hot zone to your exact material and process requirements, ensuring optimal performance, cleanliness, and longevity. Contact us today (#ContactForm) to discuss how we can design a furnace solution that guarantees your process integrity and efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing