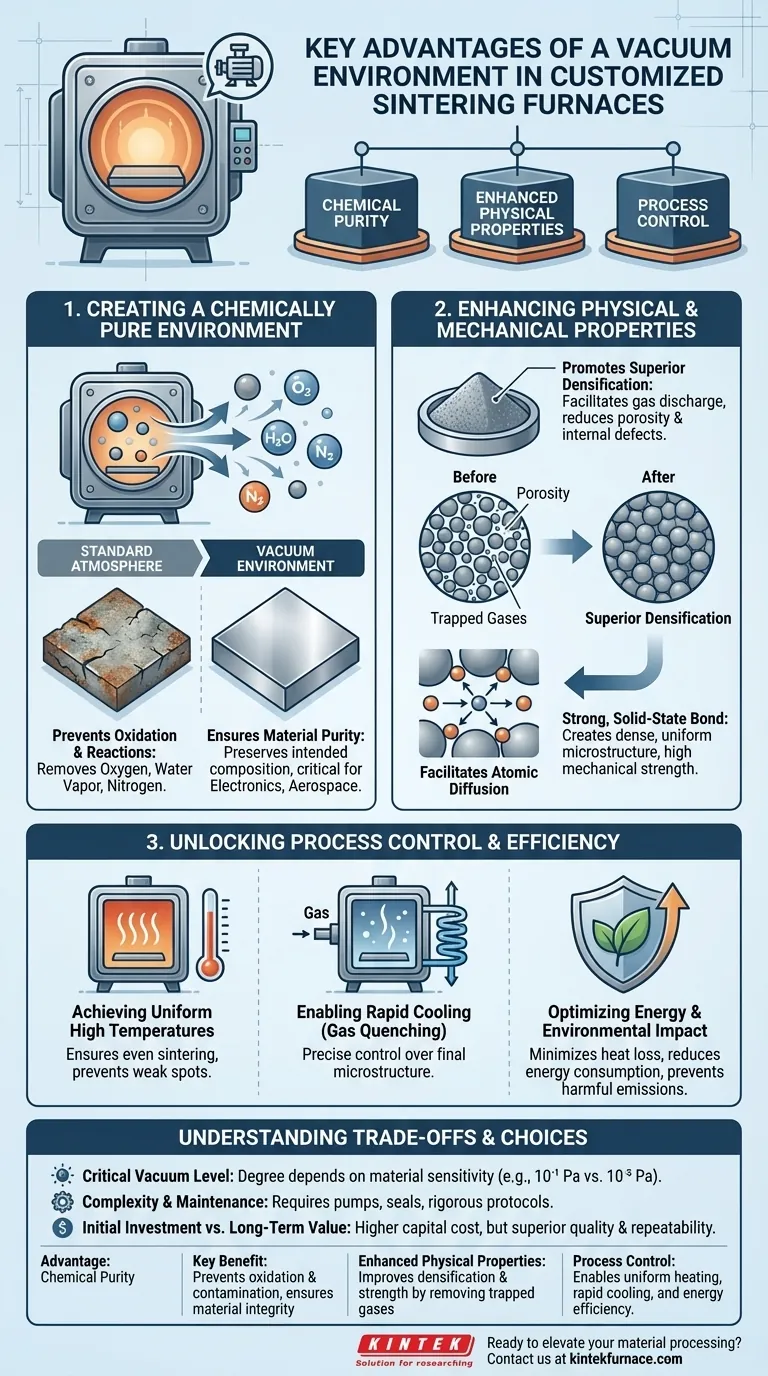

At its core, a vacuum environment in a customized sintering furnace provides three fundamental advantages: it creates a chemically pure atmosphere, enhances the physical structure of the material, and allows for unparalleled process control. By removing reactive gases like oxygen, the vacuum prevents oxidation and contamination, while the absence of atmospheric pressure facilitates the removal of trapped gases within the material, leading to superior density and strength.

The true value of a vacuum is not merely the absence of air, but the creation of a precisely controlled environment. This control allows you to fundamentally manipulate a material's chemical and physical properties to achieve a level of quality and performance that is impossible in a standard atmosphere.

The Core Function: Creating a Chemically Pure Environment

The primary role of the vacuum is to eliminate unwanted chemical reactions that degrade material quality. This is achieved by removing the atmospheric gases that would otherwise interfere with the sintering process at high temperatures.

Preventing Oxidation and Reactions

For many advanced materials, particularly reactive metals and non-oxide ceramics, exposure to oxygen at high temperatures is catastrophic. It leads to the formation of oxide layers that compromise the material's integrity.

A vacuum environment removes not only oxygen but also other harmful components like water vapor and nitrogen, preventing a wide range of unwanted chemical reactions and preserving the material's intended composition.

Ensuring Material Purity

By preventing these unintended reactions, the vacuum ensures the purity of the final product. Contamination from atmospheric gases can alter electrical, mechanical, or chemical properties.

Maintaining purity is critical in industries like electronics, medical implants, and aerospace, where even minute impurities can lead to component failure.

Enhancing Physical and Mechanical Properties

Beyond chemical purity, the vacuum directly influences the physical structure of the sintered part, leading to superior mechanical performance.

Promoting Superior Densification

Sintering involves bonding particles together to form a solid mass. Gases trapped in the pores between these particles can inhibit this process, resulting in a porous, weaker final product.

The vacuum facilitates the discharge of these trapped gases, allowing the material to consolidate more effectively. This reduction in porosity and internal defects leads to significantly higher densification.

Facilitating Atomic Diffusion

In the absence of atmospheric pressure and interfering gas molecules, atoms can move and bond more freely across particle boundaries. This enhanced atomic diffusion is the fundamental mechanism behind creating a strong, solid-state bond.

The result is a monolithic part with a dense, uniform microstructure, which is the foundation for high mechanical strength and reliability.

Unlocking Process Control and Efficiency

Customized vacuum furnaces are engineered systems where the vacuum is a key part of a highly controlled process, leading to operational and economic benefits.

Achieving Uniform High Temperatures

Vacuum is an excellent insulator. This property, combined with advanced insulation materials (like graphite) and optimized heating element distribution, allows the furnace to achieve and maintain extremely uniform temperatures.

This uniformity ensures that the entire component sinters evenly, preventing weak spots or warping.

Enabling Rapid Cooling (Gas Quenching)

While the vacuum is used for heating, the sealed chamber allows for rapid cooling by backfilling with an inert gas like argon or nitrogen. This process, known as gas quenching, provides precise control over the material's final microstructure and properties.

Optimizing Energy and Environmental Impact

The closed, well-insulated nature of a vacuum furnace minimizes heat loss, reducing energy consumption compared to atmospheric furnaces.

Furthermore, because it is a closed system, it prevents the release of harmful exhaust gases, helping to meet environmental standards and lowering the costs associated with emissions treatment.

Understanding the Trade-offs and Considerations

While powerful, vacuum sintering is a specialized process with unique requirements. Understanding these factors is crucial for successful implementation.

The Critical Role of Vacuum Level

The required "quality" of the vacuum is not one-size-fits-all. The necessary vacuum degree (e.g., 10⁻¹ Pa vs. 10⁻⁵ Pa) depends entirely on the sensitivity of the material being processed.

Choosing the wrong vacuum level can either fail to prevent oxidation or be an unnecessary and costly level of control. A customized furnace allows you to specify the precise level your process requires.

Complexity and Maintenance

Vacuum systems, with their pumps, seals, and gauges, add a layer of complexity to the equipment. While modern furnaces are designed with high automation and for easier upkeep, they demand rigorous maintenance protocols to ensure performance and longevity.

Initial Investment vs. Long-Term Value

Customized vacuum sintering furnaces represent a significant capital investment. The justification lies in the long-term value derived from superior product quality, enhanced material properties, and a highly repeatable, optimized production process that is simply not achievable otherwise.

Making the Right Choice for Your Goal

The decision to use a vacuum sintering furnace should be driven by your specific material and performance requirements.

- If your primary focus is processing oxidation-sensitive materials: The vacuum is non-negotiable for preventing chemical degradation and ensuring material purity.

- If your primary focus is achieving maximum density and mechanical strength: The vacuum environment is essential for eliminating porosity and creating a superior, high-performance final product.

- If your primary focus is process repeatability for advanced components: A customized vacuum furnace offers unmatched control over the thermal and atmospheric environment, ensuring consistent results batch after batch.

Ultimately, investing in a vacuum sintering process is about gaining precise control over your material's fundamental properties.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Purity | Prevents oxidation and contamination, ensuring material integrity |

| Enhanced Physical Properties | Improves densification and strength by removing trapped gases |

| Process Control | Enables uniform heating, rapid cooling, and energy efficiency |

Ready to elevate your material processing with a customized vacuum sintering furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your experimental requirements. Contact us today to discuss how we can help you achieve superior purity, strength, and control in your sintering processes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control