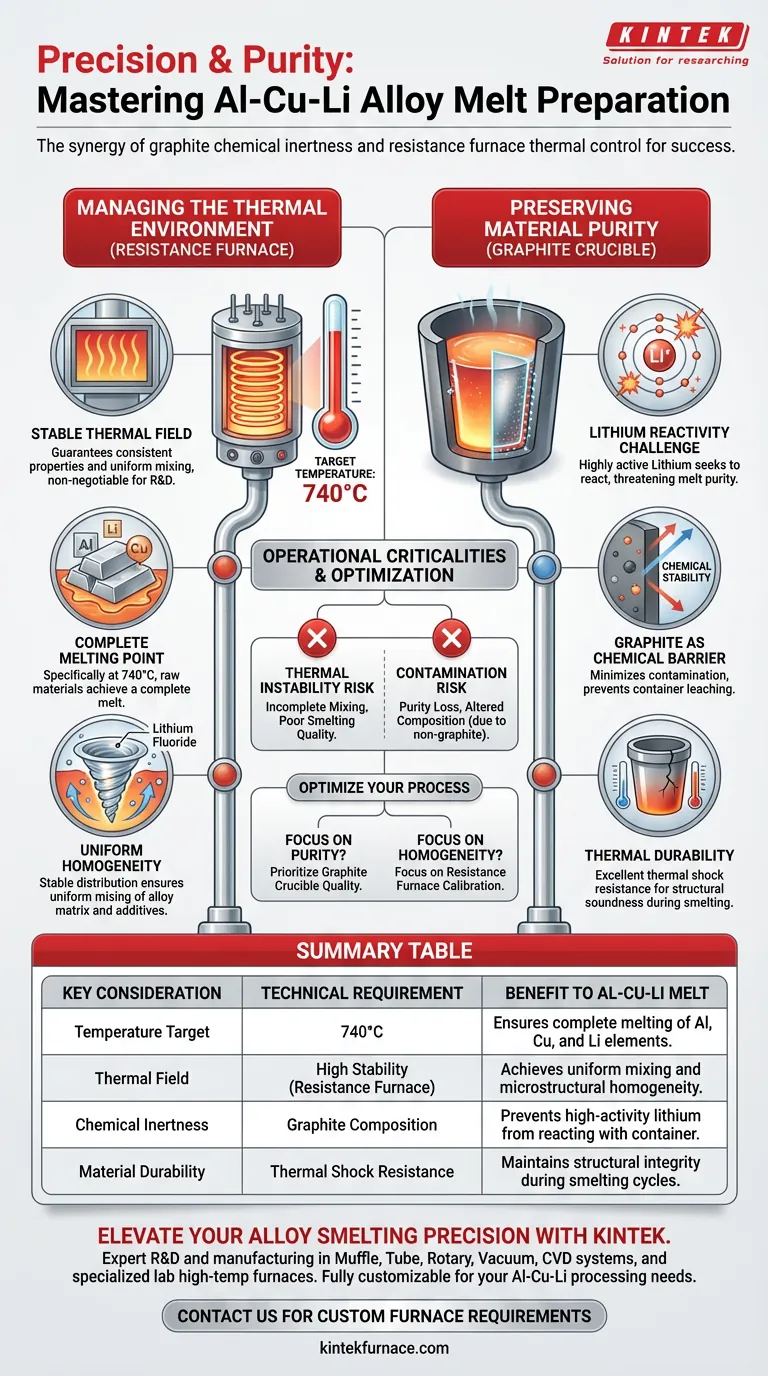

Precision and purity are the defining requirements for success. When preparing Al-Cu-Li alloy melts, your primary consideration is creating a synergy between the chemical inertness of a graphite crucible and the precise thermal control of a resistance furnace. This combination ensures that raw materials melt completely at 740°C while preventing the highly reactive lithium from interacting with the container, thereby preserving the alloy's intended composition.

The Core Insight The preparation of Aluminum-Lithium alloys is a battle against contamination and inconsistency. The industry standard utilizes a resistance furnace to guarantee a stable thermal field for uniform mixing, while relying on the chemical stability of graphite to isolate high-activity lithium from impurities.

Managing the Thermal Environment

To achieve a high-quality melt, the heating environment must be stable and precise. The resistance furnace is the tool of choice for this foundational casting process.

Achieving Precise Temperature Control

The resistance furnace provides a stable thermal field. This consistency is non-negotiable for research and development, as fluctuations can alter the material properties.

Reaching the Critical Melting Point

The process requires bringing the system to a target temperature of 740°C. At this specific heat level, the metallic raw materials—aluminum, copper, and lithium—achieve a complete melt.

Ensuring Uniform Homogeneity

Melting is not enough; the components must be evenly distributed. The stable thermal distribution of the furnace ensures the uniform mixing of the alloy matrix and additives, such as lithium fluoride.

Preserving Material Purity

The introduction of lithium into aluminum alloys creates significant chemical challenges. The choice of the crucible is the primary defense against composition drift.

The Lithium Reactivity Challenge

Lithium is a highly active element. During the melting process, it naturally seeks to react with its containment vessel, which threatens the purity of the melt.

Graphite as a Chemical Barrier

Graphite crucibles are selected specifically for their chemical stability. They effectively minimize the contamination of high-activity lithium elements, preventing the container material from leaching into the alloy.

Thermal Durability

Beyond chemical inertness, graphite offers excellent thermal shock resistance. This ensures the crucible remains structurally sound despite the rapid temperature changes inherent in the smelting process.

Operational Criticalities and Pitfalls

While this equipment combination is ideal, failing to respect the limitations of the materials or the equipment leads to compromised results.

The Cost of Thermal Instability

If the resistance furnace fails to maintain a stable thermal field, you risk incomplete mixing. Without uniform heat distribution, the aluminum matrix and lithium additives will not integrate correctly, leading to poor smelting quality.

The Risk of Contamination

Any compromise in the crucible material—or using a non-graphite alternative—can be catastrophic. Due to lithium's high activity, using a less stable container will result in purity loss, fundamentally altering the alloy's initial composition specifications.

Optimizing Your Preparation Process

To ensure the successful development of Al-Cu-Li alloys, align your equipment choices with your specific processing goals.

- If your primary focus is Alloy Purity: Prioritize the quality of the graphite crucible to ensure maximum chemical stability and prevent lithium loss or contamination.

- If your primary focus is Microstructural Homogeneity: Focus on the calibration of the resistance furnace to guarantee a perfectly stable thermal field at exactly 740°C for uniform mixing.

By strictly controlling the thermal environment and the containment material, you establish a reliable baseline for high-performance alloy casting.

Summary Table:

| Key Consideration | Technical Requirement | Benefit to Al-Cu-Li Melt |

|---|---|---|

| Temperature Target | 740°C | Ensures complete melting of Al, Cu, and Li elements. |

| Thermal Field | High Stability (Resistance Furnace) | Achieves uniform mixing and microstructural homogeneity. |

| Chemical Inertness | Graphite Composition | Prevents high-activity lithium from reacting with the container. |

| Material Durability | Thermal Shock Resistance | Maintains structural integrity during rapid smelting cycles. |

Elevate Your Alloy Smelting Precision with KINTEK

Don't let contamination or thermal instability compromise your high-performance materials. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to your unique Al-Cu-Li processing needs.

Our advanced thermal solutions guarantee the precise temperature control and chemical stability required for high-activity lithium alloying. Contact us today to discuss your custom furnace requirements and ensure your research is built on a foundation of purity and performance.

Visual Guide

References

- Meiqi Wang, Baiqing Xiong. Influence of Zn Addition on the Aging Precipitate Behavior and Mechanical Properties of Al-Cu-Li Alloy. DOI: 10.3390/ma17071562

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What maintenance advantages do multiple-chamber vacuum furnaces offer? Boost Uptime and Extend Lifespan

- Why is a magnesium vacuum distillation system essential in LME for rare earth recovery? Achieve 98% Pure Rare Earths

- How do miniature vacuum furnaces ensure image stability? Advanced Engineering for High-Resolution Ceramic Imaging

- What are the automotive industry applications of furnace brazing? Enhance Vehicle Performance with Strong, Leak-Proof Joints

- What are the main advantages of continuous furnaces? Boost Efficiency and Cut Costs in Mass Production

- What are the benefits of vacuum sintering? Achieve Superior Material Properties and Purity

- How does the multi-chamber continuous vacuum furnace improve industrial processes? Boost Efficiency and Quality

- What is the function of a laboratory vacuum drying oven for carbon cloth and LFP? Enhance Battery Stability Today