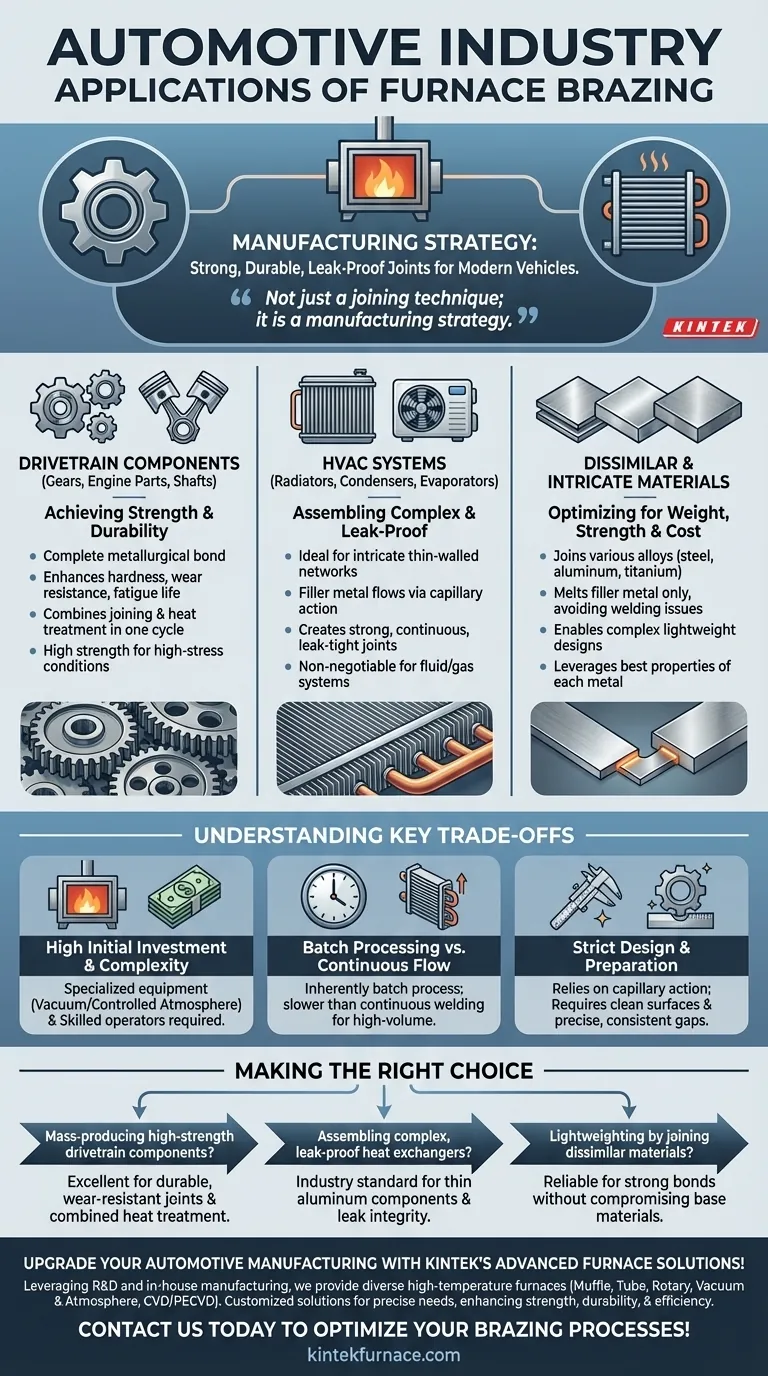

In the automotive industry, furnace brazing is primarily used to manufacture critical drivetrain components like gears and engine parts, as well as complex heating and cooling assemblies such as radiators and air conditioners. The process is chosen for its ability to create exceptionally strong, durable, and leak-proof joints, which are essential for withstanding the high-stress conditions of modern vehicles.

At its core, furnace brazing is not just a joining technique; it is a manufacturing strategy. The automotive industry relies on it to create highly reliable and complex assemblies that would be difficult or impossible to produce with traditional welding, ensuring both performance and longevity.

Why Furnace Brazing is Essential for Modern Vehicles

Furnace brazing solves several key manufacturing challenges in the automotive sector, from ensuring powertrain reliability to enabling efficient thermal management. It moves beyond simple joining to become an integrated part of creating high-performance components.

Achieving Strength and Durability in the Drivetrain

Critical components like engine parts, gears, and shafts must endure constant stress, vibration, and high temperatures. Furnace brazing creates a complete metallurgical bond across the entire joint surface.

This process significantly enhances the hardness, wear resistance, and fatigue life of these parts. By combining the joining process with heat treatment in a single furnace cycle, manufacturers can improve material properties while assembling the component, boosting both quality and efficiency.

Assembling Complex and Leak-Proof HVAC Systems

Automotive radiators, condensers, and evaporators are classic examples of heat exchangers. They consist of intricate networks of thin-walled tubes and fins, which demand a joining method that is both precise and complete.

Furnace brazing is ideal for these applications. The filler metal flows via capillary action into the tight spaces between components, creating strong, continuous joints. This ensures the entire assembly is leak-tight, a non-negotiable requirement for any fluid or gas-filled system.

Joining Dissimilar and Intricate Materials

Modern vehicles use a wide array of materials—including various steel alloys, aluminum, and titanium alloys—to optimize for weight, strength, and cost. Furnace brazing excels at joining these dissimilar metals.

Because the process melts only the filler metal and not the base components, it avoids many of the issues associated with welding different materials. This allows engineers to design complex parts that leverage the best properties of each metal.

Understanding the Key Trade-offs

While powerful, furnace brazing is a specific tool with its own set of considerations. Understanding its limitations is key to using it effectively.

High Initial Investment and Complexity

Furnace brazing requires specialized equipment, such as vacuum furnaces or controlled atmosphere furnaces. This machinery represents a significant capital investment and requires skilled operators to manage the precise temperature and atmospheric controls.

Batch Processing vs. Continuous Flow

Furnace brazing is inherently a batch process. Entire assemblies are loaded into a furnace, run through a heating and cooling cycle, and then unloaded. This can be slower than continuous processes like automated welding, making it better suited for high-value components than for simple, high-volume structural joints.

Strict Design and Preparation Requirements

The success of furnace brazing depends entirely on capillary action, which requires clean surfaces and very precise, consistent gaps between the parts being joined. This places a greater burden on the design and pre-processing stages to ensure parts fit together perfectly before entering the furnace.

Making the Right Choice for Your Goal

Selecting furnace brazing is a strategic decision based on the specific requirements of the automotive component.

- If your primary focus is mass-producing high-strength drivetrain components: Furnace brazing is an excellent choice for creating durable, wear-resistant joints in parts like gears and shafts, especially when you can combine joining and heat treatment in one step.

- If your primary focus is assembling complex, leak-proof heat exchangers: This process is the industry standard for joining thin aluminum components for radiators and A/C systems where absolute leak integrity is paramount.

- If your primary focus is lightweighting by joining dissimilar materials: Furnace brazing provides a reliable method for creating strong bonds between different metals without compromising the integrity of the base materials.

By understanding the principles behind furnace brazing, engineers can design and manufacture more robust, efficient, and reliable vehicles.

Summary Table:

| Application | Key Benefits |

|---|---|

| Drivetrain Components (e.g., gears, engine parts) | High strength, durability, and combined heat treatment |

| HVAC Systems (e.g., radiators, A/C units) | Leak-proof joints via capillary action for fluid/gas systems |

| Dissimilar Materials Joining (e.g., steel, aluminum) | Strong bonds without base material compromise, enabling lightweight designs |

Upgrade your automotive manufacturing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for your unique experimental needs, enhancing strength, durability, and efficiency in drivetrain and HVAC components. Contact us today to discuss how we can optimize your brazing processes and drive innovation in your projects!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios