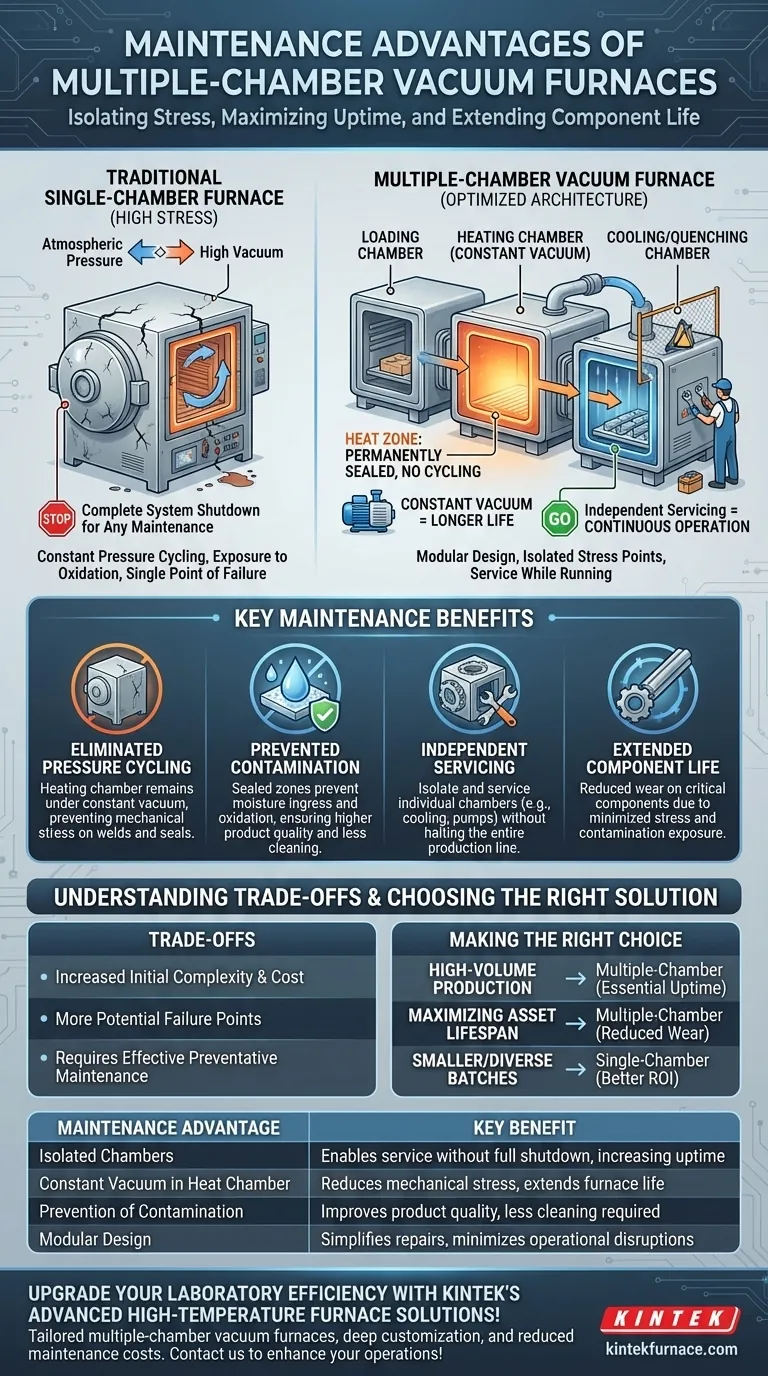

At its core, the primary maintenance advantage of a multiple-chamber vacuum furnace is its architectural design, which isolates high-stress processes and allows for service without a complete system shutdown. By separating the heating chamber from pressure cycling and enabling independent access to different modules, these furnaces dramatically increase uptime, extend the life of critical components, and reduce the risk of contamination.

The fundamental advantage is not just about easier repairs, but about preventing the need for them. Multiple-chamber designs minimize wear on the most critical components and ensure that when maintenance is required, it doesn't bring your entire operation to a halt.

The Architectural Advantage: Isolating Stress and Failure Points

The most significant maintenance benefits stem from the furnace's modular design. Unlike single-chamber units where every function happens in one space, multiple-chamber systems separate heating, quenching, and loading into distinct, independently controlled environments.

Eliminating Pressure Cycling in the Heat Chamber

In a traditional single-chamber furnace, the entire vessel is repeatedly cycled from high vacuum to atmospheric pressure for every load. This constant fluctuation creates significant mechanical stress on welds, seals, and the overall furnace casing.

Multiple-chamber furnaces solve this by keeping the heat chamber under a constant vacuum. Parts are moved from a loading chamber, through the heat chamber, and into a cooling chamber via vacuum-sealed doors.

Because the heat chamber is never exposed to atmospheric pressure, it is not subjected to this damaging cyclical stress. This directly translates to a longer furnace life and superior long-term integrity of the casing.

Preventing Oxidation and Contamination

When a hot furnace is exposed to air, ambient moisture is drawn in. This moisture can cause oxidation on internal components and contaminate subsequent product loads, requiring downtime for cleaning.

By keeping the heat-intensive zones permanently sealed and under vacuum, multiple-chamber systems prevent this recurring moisture contamination. This leads to higher product quality, greater process consistency, and less maintenance related to internal cleaning and oxidation removal.

Maximizing Uptime Through Independent Servicing

The separation of chambers is not just for process efficiency; it is a deliberate strategy for simplifying maintenance and maximizing operational availability.

Modular Design and Dedicated Access

Advanced designs, such as the "Cloverleaf" or in-line "straight-through" models, treat each chamber as a semi-independent module. This often includes dedicated vacuum pumps, instrumentation, and access doors for each section.

This modularity means a problem in one area does not necessarily disable the entire system.

The "Service While Running" Benefit

The ability to isolate chambers is the key to continuous operation. If a vacuum pump on the cooling chamber requires service, that chamber can be taken offline while the heating chamber continues to process another load.

This is impossible in a single-chamber furnace, where any maintenance on a core component requires a complete production halt. The ability to perform targeted service without shutting down the entire line is a massive advantage for high-volume production environments.

Understanding the Trade-offs

While the maintenance advantages are clear, it is crucial to understand the associated complexities and considerations before investing in this technology.

Increased Initial Complexity and Cost

A multiple-chamber furnace is inherently more complex than its single-chamber counterpart. It involves sophisticated transfer mechanisms, multiple sets of vacuum pumps, and more intricate control systems.

This complexity naturally results in a higher initial capital investment. The decision to invest must be justified by the need for high throughput and maximum uptime.

More Potential Points of Failure

While the design isolates the impact of a failure, having more components—more pumps, valves, and seals—statistically increases the number of potential failure points across the entire system.

Effective preventative maintenance and monitoring are critical to managing this increased component count and realizing the uptime benefits.

Making the Right Choice for Your Operation

The decision to use a multiple-chamber furnace should be driven by your specific production goals and operational philosophy.

- If your primary focus is high-volume, continuous production: The ability to service the furnace without halting operations makes the maintenance advantages of a multiple-chamber system essential.

- If your primary focus is maximizing asset lifespan: The elimination of pressure cycling on the heat chamber offers a compelling long-term benefit, significantly reducing wear on the most expensive furnace component.

- If your primary focus is processing smaller, diverse, or non-continuous batches: A simpler, less expensive single-chamber furnace may provide a better return on investment, as the benefits of continuous operation are less critical.

By aligning the furnace architecture with your operational needs, you ensure your investment directly supports your most important production goals.

Summary Table:

| Maintenance Advantage | Key Benefit |

|---|---|

| Isolated Chambers | Enables service without full shutdown, increasing uptime |

| Constant Vacuum in Heat Chamber | Reduces mechanical stress, extends furnace life |

| Prevention of Contamination | Improves product quality, less cleaning required |

| Modular Design | Simplifies repairs, minimizes operational disruptions |

Upgrade your laboratory efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored multiple-chamber vacuum furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, boosting uptime and reducing maintenance costs. Contact us today to discuss how we can enhance your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing