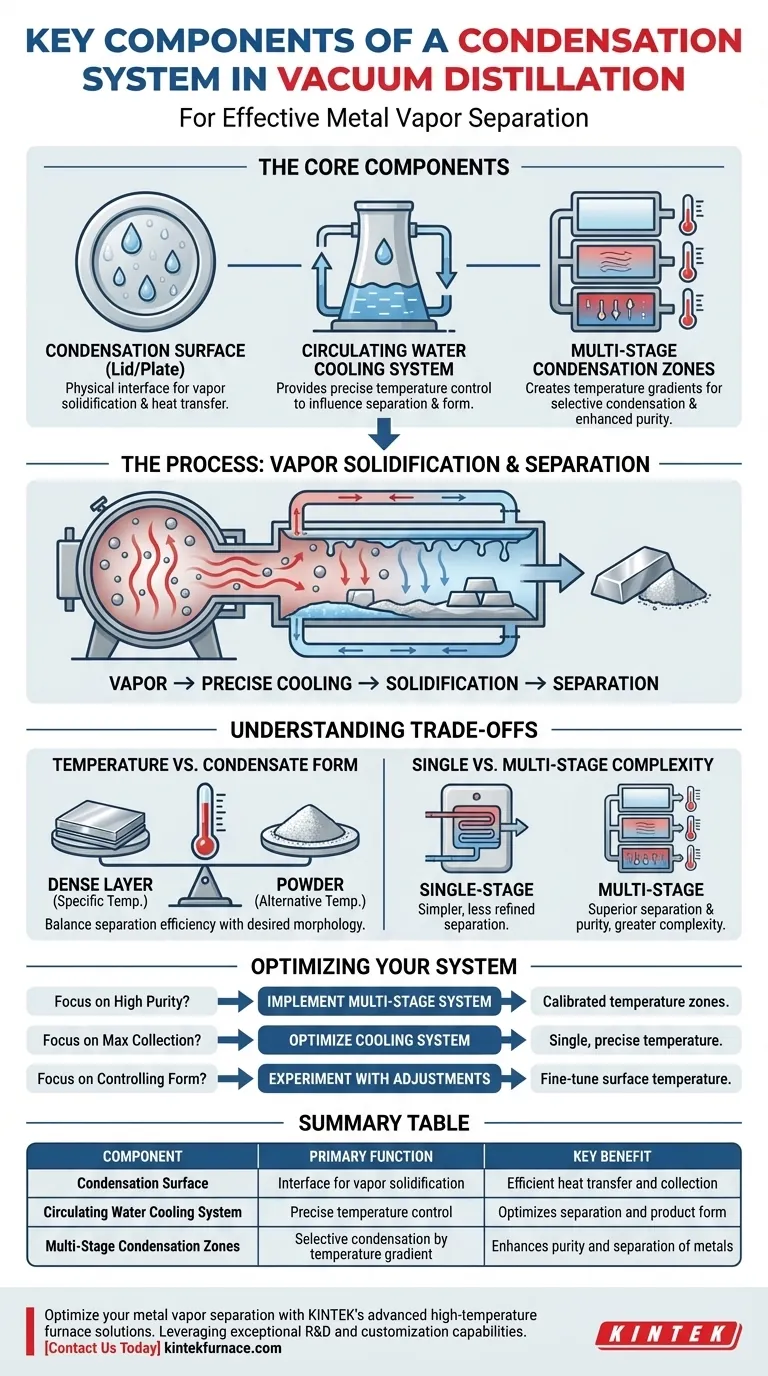

The key components of a condensation system in a vacuum distillation furnace primarily include the condensation surface, a circulating water cooling system, and often, multi-stage condensation zones. These elements work in concert to efficiently capture and separate metal vapors.

The effectiveness of a vacuum distillation condensation system hinges on precise temperature control across dedicated surfaces. This ensures optimal separation of metal vapors based on their distinct condensation points, allowing for both efficient collection and control over the condensed product's physical form.

The Role of Condensation in Vacuum Distillation

Primary Function: Vapor Solidification

In a vacuum distillation furnace, the primary goal of the condensation system is to transform metal vapors back into a solid or liquid state. This process is critical for collecting the purified metal and separating it from impurities.

Key Components for Effective Separation

The Condensation Surface

This is the physical interface where the metal vapor makes contact and solidifies. It commonly takes the form of a lid or a dedicated plate. The design and material of this surface are crucial for efficient heat transfer and collection.

Circulating Water Cooling System

An essential part of the condensation process, this system provides precise temperature control for the condensation surface. Water circulates through channels to remove heat from the condensing metal. The exact temperature influences the efficiency of separation and the final physical form of the condensed metal.

Multi-Stage Condensation Zones

Advanced systems often incorporate multiple condensation zones, each designed to operate at a specific temperature. This creates a temperature gradient across the system. Different metals and impurities, having varying vapor pressures, will condense selectively in different zones, enhancing separation purity.

Understanding the Trade-offs

Temperature Control vs. Condensate Form

The chosen condensation temperature directly impacts the physical form of the collected metal. A specific temperature might yield a dense layer, while another might result in a powdered product. Balancing separation efficiency with desired product morphology is a key consideration.

Single vs. Multi-Stage Complexity

While multi-stage systems offer superior separation and purity by leveraging temperature gradients, they introduce greater complexity in design and operation. Single-stage systems are simpler but may offer less refined separation. The choice depends on the required purity and process constraints.

Optimizing Your Condensation System

If your primary focus is high purity separation of multiple components: Implement a multi-stage condensation system with carefully calibrated temperature zones. If your primary focus is maximizing collection efficiency of a single metal: Optimize the circulating water cooling system for a single, precise temperature on the condensation surface. If your primary focus is controlling the physical form (e.g., powder vs. dense layer): Experiment with fine adjustments to the condensation surface temperature, as this directly influences the morphology.

Effective metal vapor separation in vacuum distillation relies on a thoughtfully designed and precisely controlled condensation system.

Summary Table:

| Component | Primary Function | Key Benefit |

|---|---|---|

| Condensation Surface | Interface for vapor solidification | Efficient heat transfer and collection |

| Circulating Water Cooling System | Precise temperature control | Optimizes separation and product form |

| Multi-Stage Condensation Zones | Selective condensation by temperature gradient | Enhances purity and separation of metals |

Optimize your metal vapor separation with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with condensation systems tailored for precise temperature control and efficient separation. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how we can enhance your vacuum distillation process!

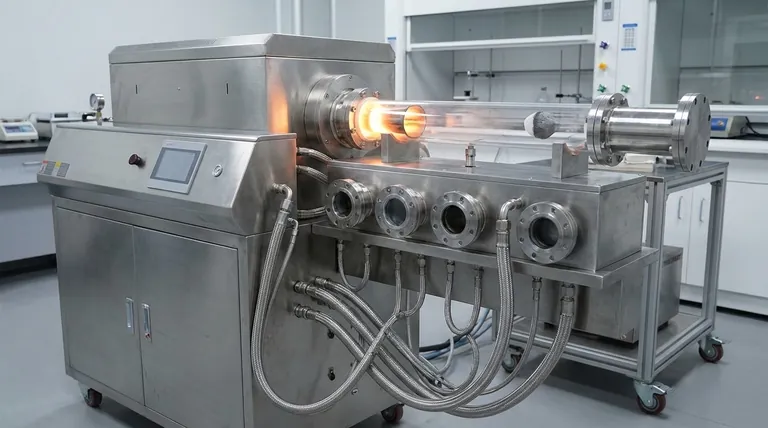

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision