At its core, a Chemical Vapor Deposition (CVD) Tube Furnace is essential because it provides an exceptionally precise and controllable high-temperature environment. This control over both temperature and atmospheric conditions is the fundamental requirement for synthesizing and processing the advanced materials that drive innovation in material science and nanotechnology, from growing flawless graphene sheets to developing next-generation electronic ceramics.

The true value of a CVD Tube Furnace is not merely its ability to get hot, but its function as a high-precision reactor. It allows researchers to dictate the exact conditions under which atoms assemble into novel materials, turning theoretical science into tangible, high-performance components.

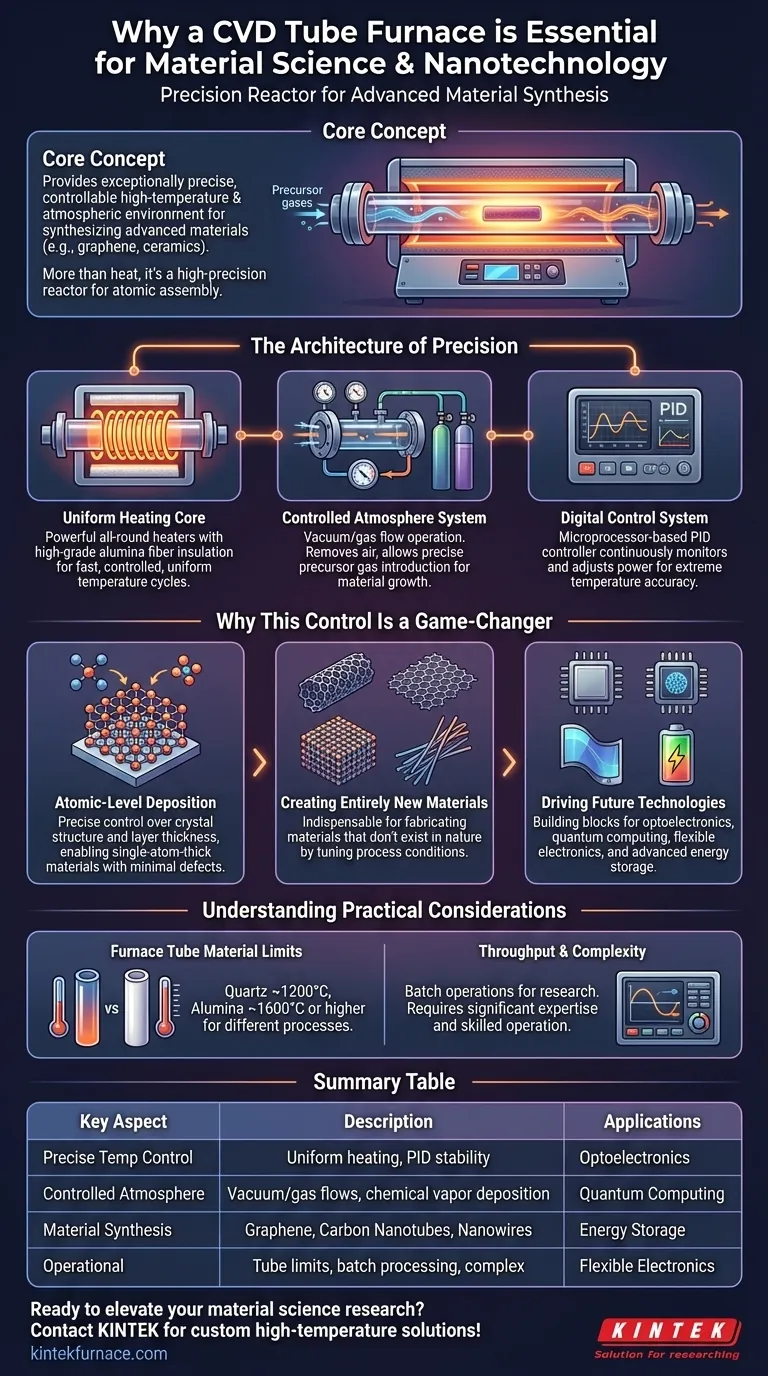

The Architecture of Precision

To understand why this furnace is so critical, we must look at its core components, which are engineered to work in concert to create a highly stable and customizable processing environment.

The Uniform Heating Core

A defining feature is its ability to heat a sample uniformly from all sides. This is achieved through powerful all-round heaters that encircle the furnace tube.

High-grade alumina fiber insulation minimizes heat loss, ensuring temperature stability and energy efficiency. This design leads to fast, controlled heating and cooling cycles.

The Controlled Atmosphere System

The furnace is designed to operate under vacuum or with a specific flow of gases. This is the "Chemical Vapor Deposition" aspect of the process.

Vacuum-sealed flanges (often SS KF-type) allow all air to be removed from the furnace tube. This prevents unwanted reactions with oxygen or nitrogen.

Once under vacuum, precursor gases can be introduced in precise amounts. These gases contain the elements needed to "deposit" and grow the desired material on a substrate.

The Digital Control System

The entire process is governed by a microprocessor-based PID controller. This system is the brain of the operation.

It continuously monitors the temperature and adjusts the power to the heaters to maintain the setpoint with extreme accuracy. This prevents temperature overshoots or drops that could ruin a sensitive material growth process.

Why This Control Is a Game-Changer

The combination of thermal and atmospheric control unlocks capabilities that are simply not possible with other heating methods. It moves beyond simple heating to become an instrument of atomic-scale construction.

Enabling Atomic-Level Deposition

CVD processes are fundamentally about building materials layer by layer. The furnace's stability allows for precise control over crystal structure and layer thickness.

For materials like graphene or transition metal dichalcogenides (TMDs), this means growing single-atom-thick sheets with minimal defects, which is essential for their remarkable electronic and optical properties.

Creating Entirely New Materials

This tool is indispensable for fabricating materials that don't readily exist in nature. It's the primary method used for producing carbon nanotubes (CNTs), graphene, and nanowires.

By carefully selecting the substrate, temperature, pressure, and precursor gases, researchers can tune the properties of these materials for specific applications.

Driving Future Technologies

The materials created in CVD furnaces are the building blocks for breakthrough technologies. They are driving innovation in optoelectronics, quantum computing, flexible electronics, and advanced energy storage.

Without the ability to reliably produce these high-purity, structurally perfect materials, progress in these fields would be significantly slower.

Understanding the Practical Considerations

While powerful, a CVD Tube Furnace is a specialized piece of equipment with operational trade-offs that must be considered.

Furnace Tube Material Limits

The furnace tube itself dictates the maximum operating temperature. Quartz tubes are common and cost-effective but are typically limited to around 1200°C.

For higher temperature processes, such as sintering certain ceramics, more expensive alumina tubes are required, which can withstand temperatures of 1600°C or higher.

Throughput and Process Scale

Most lab-scale tube furnaces are designed for periodic or batch operations, not continuous manufacturing. They are ideal for research, development, and small-scale production.

Scaling a CVD process for industrial production often requires moving to different, more complex reactor designs to achieve higher throughput.

Operational Complexity

Achieving consistent, high-quality results requires significant expertise. The process is highly sensitive to small variations in gas flow rates, pressure, temperature ramps, and substrate preparation. It is a powerful tool that demands a skilled operator.

How to Apply This to Your Goal

Your choice and use of a CVD Tube Furnace should be directly informed by your primary research or production objective.

- If your primary focus is novel nanomaterial synthesis (graphene, CNTs): Prioritize a system with precise mass flow controllers and high-vacuum capabilities to ensure atomic-level control over the growth atmosphere.

- If your primary focus is advanced ceramic processing: Ensure the furnace is equipped with a high-temperature alumina tube and a controller capable of executing complex, multi-stage heating and cooling profiles.

- If your primary focus is general material testing and annealing: A more versatile furnace with interchangeable tube sizes and robust temperature cycling capabilities will provide the most flexibility.

Ultimately, the CVD Tube Furnace empowers scientists and engineers to move beyond observing materials to actively designing and building them from the ground up.

Summary Table:

| Key Aspect | Description |

|---|---|

| Precise Temperature Control | Achieves uniform heating with PID controllers for stable, accurate thermal environments. |

| Controlled Atmosphere | Supports vacuum or gas flows to prevent contamination and enable chemical vapor deposition. |

| Material Synthesis Capabilities | Essential for growing graphene, carbon nanotubes, and nanowires with minimal defects. |

| Applications | Drives innovations in optoelectronics, quantum computing, and energy storage technologies. |

| Operational Considerations | Includes tube material limits (e.g., quartz to 1200°C, alumina to 1600°C) and batch processing for labs. |

Ready to elevate your material science research with a custom high-temperature furnace solution? KINTEK specializes in advanced CVD Tube Furnaces, Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—whether you're synthesizing nanomaterials or processing advanced ceramics. Contact us today to discuss how our solutions can drive your innovations forward!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials