In the field of advanced materials, Chemical Vapor Deposition (CVD) tube furnace systems are considered indispensable because they provide the trifecta of control required for 2D material synthesis: precise temperature management, a highly controlled atmospheric environment, and a scalable design. These capabilities are the absolute foundation for producing high-quality, uniform, atom-thin layers of materials like graphene, Transition Metal Dichalcogenides (TMDs), and hexagonal boron nitride (h-BN).

The core challenge of 2D materials is creating a perfect, large-area crystalline film that is only a single atom thick. A CVD tube furnace is not just a heater; it is a precisely controlled micro-environment that makes this atomic-level construction possible and repeatable.

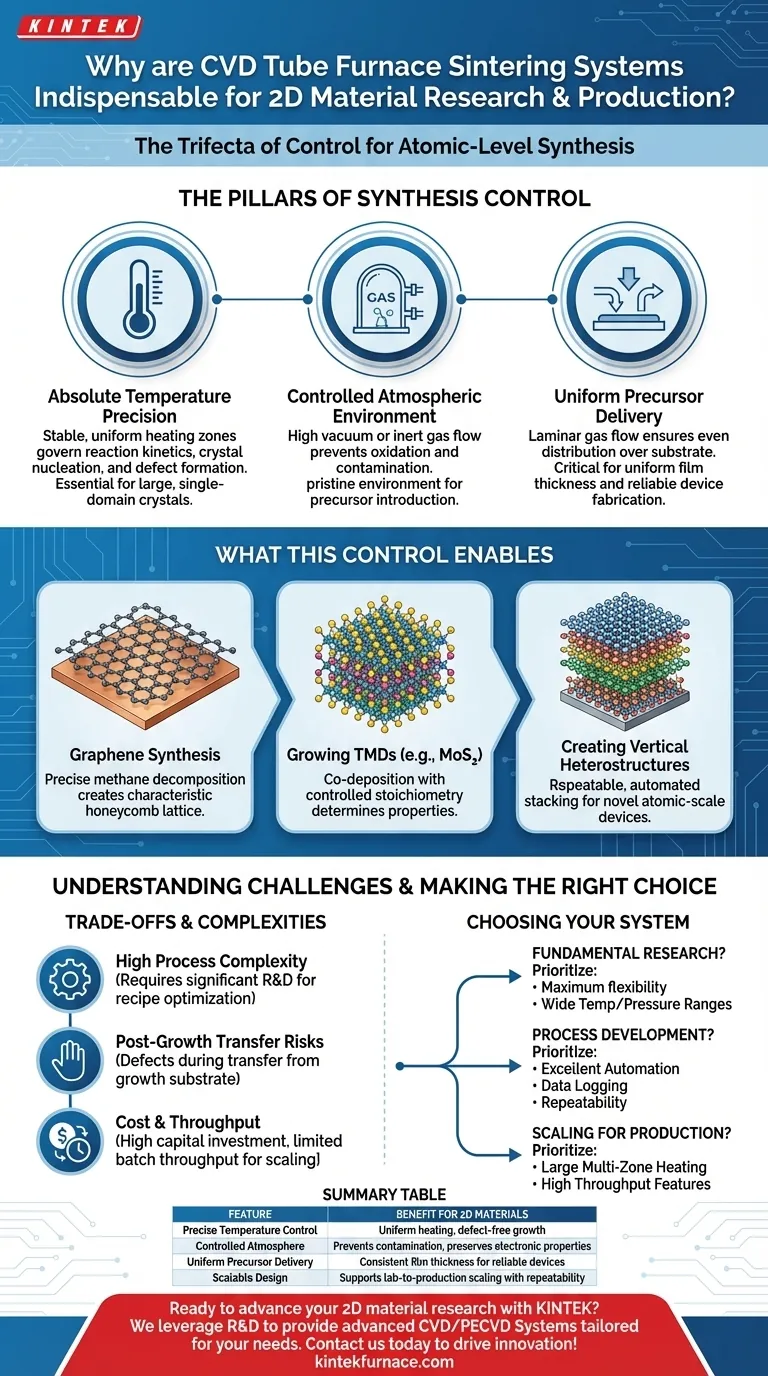

The Pillars of Synthesis Control

To build materials atom-by-atom, you must have absolute authority over the construction environment. A CVD furnace provides this authority through several key features that are non-negotiable for 2D material growth.

Absolute Temperature Precision

The temperature within the furnace directly governs reaction kinetics, crystal nucleation, and defect formation. Even minor fluctuations can ruin the quality of a 2D film.

CVD tube furnaces create exceptionally stable and uniform heating zones, ensuring the entire substrate is at the exact same temperature. This uniformity is critical for growing large, single-domain crystals instead of a patchwork of small, defective ones.

Controlled Atmospheric Environment

2D materials are highly susceptible to contamination, especially oxidation from ambient air, which can destroy their desired electronic properties.

These systems operate under high vacuum or with a continuous flow of high-purity inert gases, creating a pristine environment. This allows for the introduction of specific precursor gases (the chemical building blocks) without risk of unwanted side reactions.

Uniform Precursor Delivery

The "Chemical Vapor Deposition" process relies on delivering reactive gases to a heated substrate. The furnace's design ensures these gases flow smoothly and evenly over the substrate surface.

This laminar flow is essential for achieving a uniform film thickness across the entire sample, a key requirement for reliable device fabrication in fields like semiconductor manufacturing and optoelectronics.

What This Control Enables

The precision of a CVD furnace unlocks the ability to synthesize a wide spectrum of 2D materials, from the simplest single-element films to complex, multi-layered structures.

Graphene Synthesis

Graphene is typically grown by flowing a carbon-containing gas, like methane, over a heated copper foil. The furnace's precise temperature control is what decomposes the methane at the right rate, allowing carbon atoms to arrange themselves into the characteristic honeycomb lattice.

Growing Transition Metal Dichalcogenides (TMDs)

Materials like molybdenum disulfide (MoS₂) require the co-deposition of multiple precursors (e.g., molybdenum and sulfur compounds). The CVD system's advanced gas mixing capabilities allow for precise control over the stoichiometric ratio, which determines the final material's properties.

Creating Vertical Heterostructures

This advanced technique involves stacking different 2D materials on top of one another to create novel devices. The repeatable, automated nature of modern CVD systems is essential for growing one layer, changing the gas recipe, and then growing a second, distinct layer on top with atomic precision.

Understanding the Trade-offs and Challenges

While indispensable, CVD tube furnace systems are not without their complexities. Acknowledging these is key to successful implementation.

High Process Complexity

A CVD furnace provides the tools for control, but it does not provide the "recipe." Developing a successful growth process requires significant R&D to optimize gas flow rates, pressure, temperature ramps, and cooling profiles.

Post-Growth Transfer Risks

For many applications, the 2D film must be transferred from its growth substrate (e.g., copper foil) to a final target substrate (e.g., a silicon wafer). This delicate process is a major source of defects, tears, and contamination that can compromise material quality.

Cost and Throughput

High-purity gases, vacuum components, and the furnace itself represent a significant capital investment. Furthermore, as a batch process, traditional tube furnaces can have limited throughput, which is a key challenge when scaling from lab research to industrial production.

Making the Right Choice for Your Goal

The optimal CVD system configuration is dictated entirely by your end goal, whether it's pure discovery or industrial manufacturing.

- If your primary focus is fundamental research: Prioritize systems with maximum flexibility in gas mixing, wide temperature ranges, and precise pressure control to explore novel materials and synthesis pathways.

- If your primary focus is process development: Seek a system with excellent automation, data logging, and process repeatability to standardize a growth recipe for consistent results.

- If your primary focus is scaling for production: Emphasize furnaces with large, multi-zone heating elements for superior uniformity over large areas and features that support higher throughput and batch-to-batch consistency.

Ultimately, mastering the CVD tube furnace is mastering the ability to engineer matter at the atomic scale.

Summary Table:

| Feature | Benefit for 2D Materials |

|---|---|

| Precise Temperature Control | Ensures uniform heating for defect-free, large-area crystal growth |

| Controlled Atmospheric Environment | Prevents contamination and oxidation, preserving electronic properties |

| Uniform Precursor Delivery | Achieves consistent film thickness for reliable device fabrication |

| Scalable Design | Supports both lab research and industrial production with repeatable results |

Ready to advance your 2D material research with precision-engineered solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including CVD/PECVD Systems, tailored for laboratories and production facilities. Our deep customization capabilities ensure your unique experimental needs are met with reliable, scalable performance. Contact us today to discuss how our expertise can enhance your material synthesis and drive innovation!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films