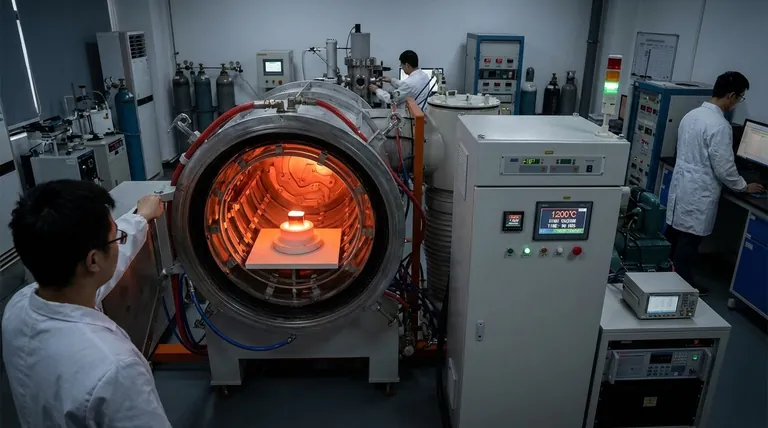

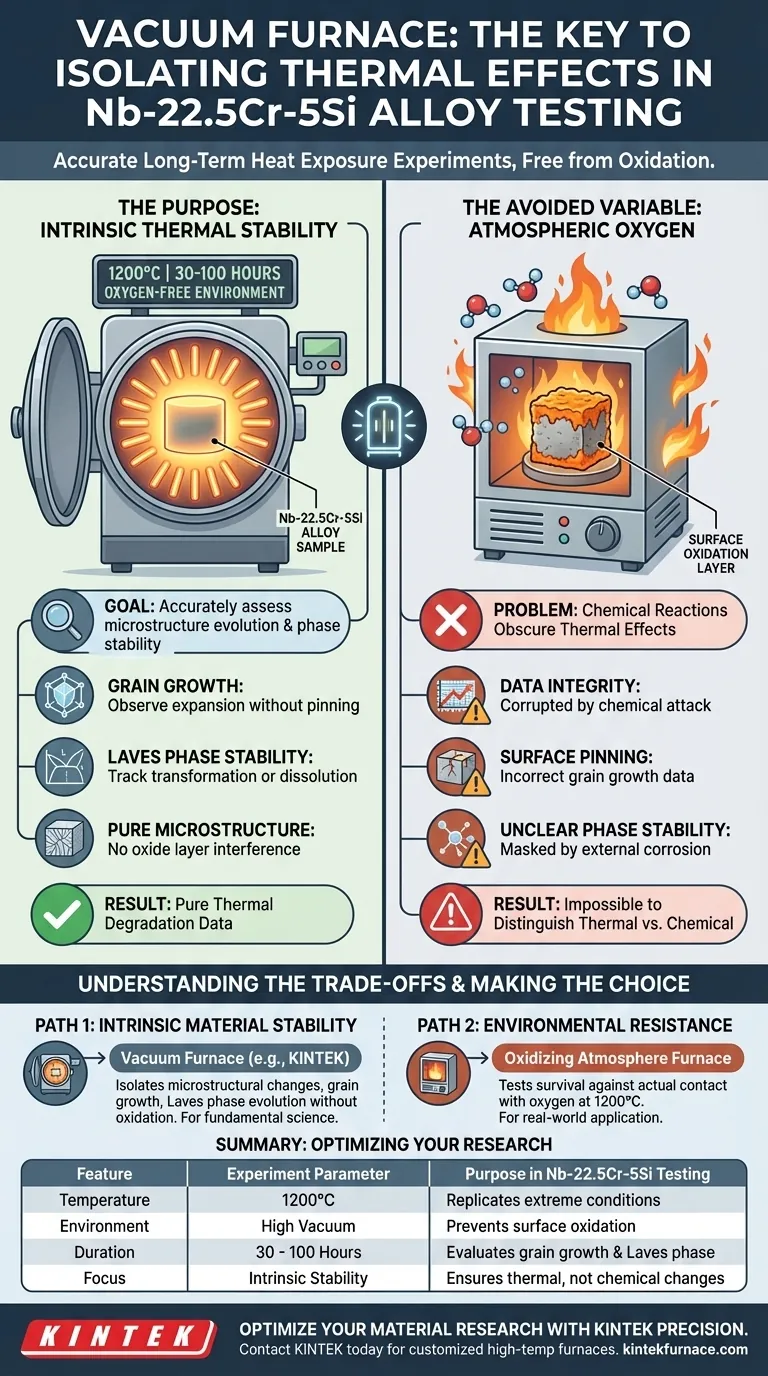

The primary role of a vacuum furnace in this context is to isolate thermal effects from chemical reactions. By creating an oxygen-free environment, researchers can subject Nb-22.5Cr-5Si alloys to temperatures of 1200°C for durations ranging from 30 to 100 hours to simulate service conditions without the data-corrupting influence of surface oxidation.

By removing atmospheric oxygen, a vacuum furnace ensures that any observed changes in the alloy are purely intrinsic. This allows for an accurate assessment of microstructure evolution and phase stability, unclouded by external environmental corrosion.

Simulating High-Temperature Service Conditions

To understand how Nb-22.5Cr-5Si alloys will perform in real-world applications, researchers must replicate extreme thermal environments.

Replicating Extreme Heat

The vacuum furnace allows the alloy to be heated to 1200°C, a critical threshold for advanced high-temperature materials.

This temperature mimics the intense conditions the material would face during actual operation, such as in aerospace or power generation components.

Evaluating Long-Term Durability

Short-term heating is often insufficient to predict component life.

The vacuum furnace maintains this heat for extended periods—specifically 30, 50, or 100 hours.

This extended exposure is necessary to drive slow-moving atomic processes that only reveal themselves over time.

Ensuring Data Integrity via Isolation

The scientific value of these experiments relies on controlling variables. The most disruptive variable at high temperatures is oxygen.

Preventing Surface Oxidation

At 1200°C, many metals react aggressively with oxygen.

Without a vacuum, a thick oxide layer would form on the surface of the Nb-22.5Cr-5Si alloy.

This oxidation layer would obscure the underlying material, making it impossible to distinguish between thermal degradation and chemical attack.

Assessing Microstructure Evolution

The goal of the experiment is to see how the internal structure of the metal changes solely due to heat.

Researchers look for grain growth—the expansion of crystal structures which can alter strength and ductility.

The vacuum environment ensures that grain growth data is accurate and not influenced by surface pinning from oxides.

Monitoring Phase Stability

Complex alloys contain different crystalline phases that give them strength, such as the Laves phase.

Prolonged heating can cause these phases to dissolve or transform, weakening the material.

Using a vacuum furnace allows researchers to track the stability of the Laves phase directly, ensuring the alloy retains its intended properties over time.

Understanding the Trade-offs

While vacuum furnaces are essential for fundamental materials science, they present specific limitations regarding real-world applicability.

The "Perfect World" Limitation

A vacuum furnace creates an idealized environment.

It successfully tests thermal stability, but it ignores environmental resistance.

If the final application of the alloy involves exposure to air (as with jet engines), a vacuum test will not reveal how the material copes with actual oxidation or hot corrosion.

Complexity and Cost

Vacuum heat treatment is inherently more complex than standard atmospheric heating.

It requires specialized equipment to maintain high-vacuum integrity, ensuring that no impurity gases or water vapor compromise the sample.

Making the Right Choice for Your Goal

When designing experiments for high-performance alloys, your equipment choice dictates the data you receive.

- If your primary focus is Intrinsic Material Stability: Use a vacuum furnace to isolate microstructural changes, grain growth, and Laves phase evolution without interference from oxidation.

- If your primary focus is Environmental Resistance: You must eventually move to oxidizing atmospheres (standard furnaces) to test how the material survives actual contact with oxygen at 1200°C.

Use the vacuum furnace to prove the alloy's internal structure is stable, then test its surface resistance separately.

Summary Table:

| Feature | Experiment Parameter | Purpose in Nb-22.5Cr-5Si Testing |

|---|---|---|

| Temperature | 1200°C | Replicates extreme aerospace/power service conditions |

| Environment | High Vacuum | Prevents surface oxidation and data-corrupting reactions |

| Duration | 30 - 100 Hours | Evaluates grain growth and Laves phase stability |

| Focus | Intrinsic Stability | Ensures observed changes are purely thermal, not chemical |

Optimize Your Material Research with KINTEK Precision

Precise control over your thermal environment is the difference between accurate data and costly errors. KINTEK provides advanced, customizable thermal solutions designed for the most demanding R&D applications. Whether you are investigating microstructure evolution or phase stability in complex alloys, our high-performance Vacuum, Muffle, Tube, and CVD systems deliver the isolation and uniformity you need.

Backed by expert R&D and manufacturing, KINTEK offers lab high-temp furnaces tailored to your unique specifications.

Ready to elevate your material testing? Contact KINTEK today to discuss your project requirements and find the perfect furnace for your laboratory.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does vacuum or protective atmosphere melting improve the quality of aerospace materials? Achieve Superior Purity and Performance

- Why is a high-temperature vacuum furnace required for in situ heating experiments involving Tantalum?

- How does vacuum hardening affect the hardness and surface layer of high-alloy tool steel? Boost Performance with Superior Heat Treatment

- Why must NaF and KF raw materials be processed in a vacuum oven for FUNaK synthesis? Ensure Purity and Safety

- How does a crucible furnace operate? Master Indirect Heating for Pure Metal Melting

- Why is a vacuum arc-melting furnace preferred for Co-Ti-V quaternary superalloys? Ensure Purity & High-Temp Precision

- Why is a high-precision vacuum heat treatment furnace necessary for GCr15 specimens? Ensure Reliable Data Accuracy

- How are most vacuum furnaces heated? Discover the Core Heating Methods and Their Applications