In short, the insulation material in a vacuum furnace serves two critical functions: it minimizes heat loss to improve energy efficiency and maintain external safety, and it ensures uniform temperature distribution within the hot zone. These roles are essential for achieving the precise, repeatable, and high-quality results that vacuum processing is designed to deliver.

While the vacuum itself prevents chemical contamination from the atmosphere, the insulation is what prevents thermal failure. It is the component that guarantees the extreme heat is both contained and evenly distributed, a non-negotiable factor for successful high-temperature processing.

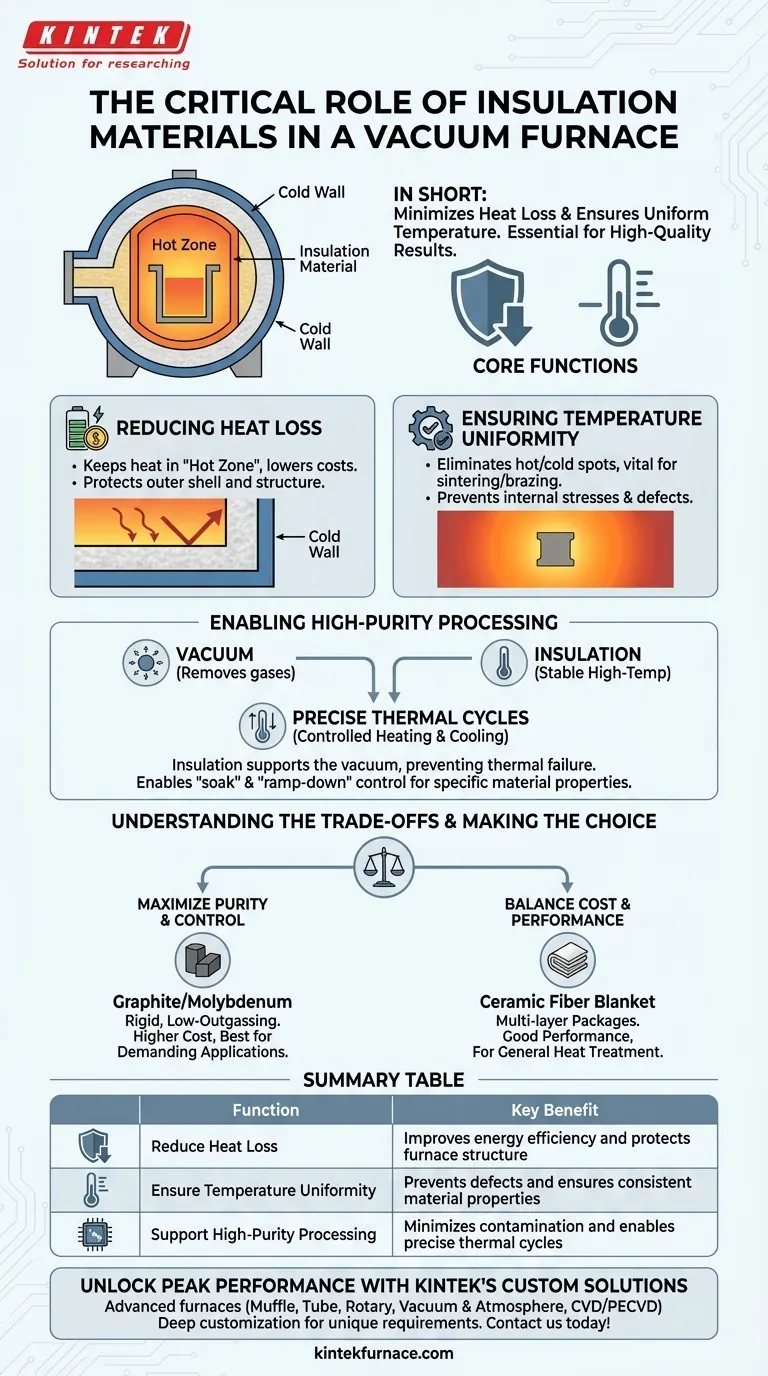

The Core Functions of Vacuum Furnace Insulation

A vacuum furnace's success hinges on precise control over its environment. While the vacuum pump removes reactive gases, the insulation system manages the thermal energy.

Reducing Heat Loss

The most obvious role of insulation is to keep the heat inside the furnace's "hot zone."

This dramatically reduces the energy required to reach and maintain target temperatures, lowering operational costs.

Crucially, it also protects the furnace's outer shell—often a water-cooled "cold wall"—from the extreme internal temperatures, ensuring the structural integrity and safety of the entire system.

Ensuring Temperature Uniformity

Perhaps more important than efficiency is the role of insulation in creating a uniform thermal environment.

Many high-temperature processes, such as sintering or brazing, are extremely sensitive to temperature variations. A difference of just a few degrees across a part can lead to internal stresses, inconsistent material properties, or complete failure.

A well-designed insulation package reflects and contains heat, eliminating hot and cold spots and ensuring every part of the workload experiences the exact same thermal conditions.

How Insulation Enables High-Purity Processing

The insulation's thermal role is deeply interconnected with the furnace's primary goal: creating a contamination-free environment for processing sensitive materials.

Complementing the Vacuum Environment

A vacuum is created to eliminate oxygen and other reactive gases that cause oxidation and contamination.

Insulation supports this by enabling stable, high-temperature operation. Without effective insulation, maintaining the heat necessary for processes like sintering would be inefficient and difficult to control.

The vacuum prevents chemical reactions, while the insulation provides the stable thermal energy needed to drive the desired physical or metallurgical changes.

Enabling Precise Thermal Cycles

Advanced manufacturing requires precise control over heating and cooling rates.

The insulation's ability to contain energy allows for highly controlled and repeatable thermal cycles. It helps the system hold a specific temperature ("soak") with minimal fluctuation and enables predictable ramp-down rates.

This control is essential for achieving specific microstructures in metals or ensuring the complete densification of powdered materials during sintering.

Understanding the Trade-offs

Choosing an insulation material is not a simple decision. It involves balancing performance, cost, and the specific demands of the process.

Material Purity vs. Performance

The insulation itself must not become a source of contamination. At extreme temperatures and in a hard vacuum, some materials can outgas, releasing volatile compounds that contaminate the product.

Materials like high-purity graphite or specific ceramic boards offer excellent insulation and low outgassing, but often come at a higher cost.

Less expensive materials like ceramic fiber blankets might be effective insulators but could be unsuitable for processes requiring the absolute highest level of purity.

Durability and Lifespan

The intense thermal cycling inside a vacuum furnace puts immense stress on all components, including the insulation.

Materials can become brittle, shrink, or degrade over time, reducing their effectiveness and potentially shedding particles that create another source of contamination.

The choice of insulation often involves a trade-off between upfront cost and the expected lifespan and maintenance requirements.

Making the Right Choice for Your Goal

The ideal insulation depends entirely on your primary processing objective.

- If your primary focus is achieving maximum process purity and temperature control: Prioritize rigid, low-outgassing materials like high-purity graphite board or molybdenum-based shields for the most demanding applications.

- If your primary focus is general heat treatment with a balance of cost and performance: Consider multi-layer insulation packages using materials like ceramic fiber blankets, which offer good thermal performance for a wider range of applications.

Ultimately, viewing insulation as a critical control element—just as important as the vacuum system—is the key to unlocking the full potential of your furnace.

Summary Table:

| Function | Key Benefit |

|---|---|

| Reduce Heat Loss | Improves energy efficiency and protects furnace structure |

| Ensure Temperature Uniformity | Prevents defects and ensures consistent material properties |

| Support High-Purity Processing | Minimizes contamination and enables precise thermal cycles |

Unlock Peak Performance with KINTEK's Custom Vacuum Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need insulation for maximum purity or cost-effective performance, we deliver tailored systems that enhance efficiency, ensure uniform heating, and support contamination-free processing.

Contact us today to discuss how our expertise can optimize your high-temperature applications!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do customized vacuum furnaces contribute to energy efficiency? Unlock Cost Savings and Eco-Friendly Processing

- How does a retort furnace differ from a vacuum furnace? Choose the Right Heat Treatment for Your Materials

- How does the absence of oxygen in vacuum furnaces benefit metal processing? Achieve Cleaner, Stronger Metal Parts

- Which industries benefit from vacuum furnaces? Unlock Material Perfection for Aerospace, Medical, and More

- Why use a vacuum drying oven for mesoporous silica? Protect High Surface Area and Structural Integrity

- What is the function of a vacuum constant temperature drying oven in the electrode coating process? Optimize Adhesion

- What are the selection criteria for vacuum pumps in vacuum furnaces? Optimize for Purity and Efficiency

- How does a vacuum furnace improve smelting quality? Achieve Purer, Stronger Metals for Your Applications