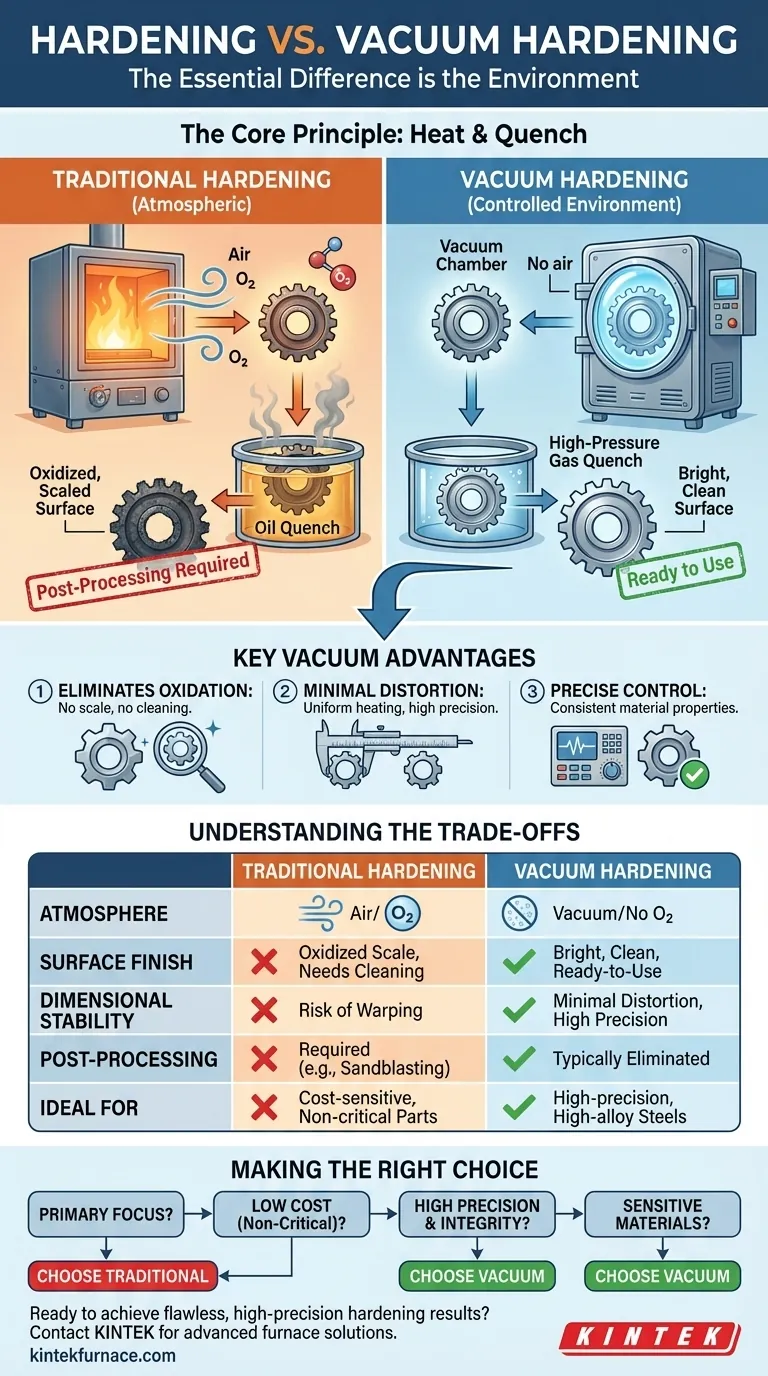

At its core, vacuum hardening is not a fundamentally different process from traditional hardening, but rather a superior environment in which hardening takes place. While all hardening involves heating and rapid cooling to increase metal strength, vacuum hardening performs this process inside a vacuum chamber. This single change eliminates surface oxidation and contamination, delivering a cleaner, more precise, and dimensionally stable final product.

The essential difference is the atmosphere. Traditional hardening occurs in air, leading to surface scale that must be removed. Vacuum hardening occurs without air, resulting in a bright, clean surface that requires no post-processing and suffers minimal distortion.

What is Hardening? A Foundational Overview

Hardening is a category of heat treatment processes designed to increase the hardness, and therefore the strength and wear resistance, of a metal. It is a cornerstone of metallurgy for creating durable components.

The Core Principle: Heat and Quench

The process involves heating a metal, typically steel, to a specific critical temperature. At this temperature, its internal crystal structure changes to a phase called austenite.

The metal is then cooled rapidly in a process called quenching. This rapid cooling traps the crystal structure in a new, very hard and brittle phase called martensite. This is what makes the metal hard.

The Problem with Atmosphere

When performed in a standard furnace, the metal is heated in the presence of oxygen. The hot metal surface reacts with this oxygen, creating a layer of oxide scale. This scale is undesirable and must be cleaned off later through processes like sandblasting or grinding.

How Vacuum Hardening Redefines the Process

Vacuum hardening follows the same heat-and-quench principle but performs the entire cycle within a vacuum furnace. This controlled environment provides significant advantages.

Eliminating Surface Reactions

By removing the air from the furnace chamber to create a vacuum or a controlled partial pressure, reactive gases like oxygen are eliminated. This prevents the formation of oxide scale entirely.

The process can achieve temperatures up to 1,300 °C while maintaining an environment free from contamination.

The Result: A Bright, Clean Surface

Because no oxidation occurs, the metal part emerges from the furnace with a bright, clean metallic surface. This eliminates the need for any secondary cleaning or finishing operations, saving time and preserving the part's original surface.

Precision Through Control

The controlled vacuum environment also allows for extremely uniform heating and cooling. This reduces thermal stress on the component, resulting in minimal distortion or deformation. For parts with tight dimensional tolerances, this level of precision is critical.

Understanding the Trade-offs

Choosing between traditional and vacuum hardening is a decision based on the specific requirements of the component, particularly concerning quality and cost.

Surface Finish and Post-Processing

With traditional hardening, you must plan for subsequent cleaning steps to remove scale. This adds time, cost, and can slightly alter the part's surface dimensions.

Vacuum hardening delivers a part that is often ready for use immediately after treatment, with no need for costly and potentially damaging mechanical cleaning.

Dimensional Stability

The non-uniform heating and cooling of atmospheric furnaces can cause parts to warp. While this can be managed, it presents a risk.

Vacuum hardening provides superior dimensional stability, making it the preferred method for complex geometries, thin sections, and high-precision components where any distortion would lead to failure.

Cost and Environmental Impact

Vacuum hardening is generally a more expensive process due to the complexity and cost of the equipment. However, this initial cost can be offset by eliminating the need for post-processing.

It is also an environmentally friendlier process, as the controlled quench (often using inert gas) reduces the emissions and waste associated with traditional oil or water quenching.

Making the Right Choice for Your Application

Your final decision should be guided by the end-use requirements of your component.

- If your primary focus is low cost for non-critical parts: Traditional hardening is often sufficient, provided you account for the necessary post-treatment cleaning.

- If your primary focus is high precision and surface integrity: Vacuum hardening is the superior choice, delivering clean, dimensionally accurate parts without secondary operations.

- If you are working with high-alloy tool steels or sensitive materials: The precise control of vacuum hardening is essential to prevent undesirable surface reactions and ensure optimal material properties.

Ultimately, choosing the right hardening process is a strategic decision that balances final part requirements against total project costs.

Summary Table:

| Feature | Traditional Hardening | Vacuum Hardening |

|---|---|---|

| Atmosphere | Air (Oxygen present) | Vacuum (No oxygen) |

| Surface Finish | Oxidized scale requiring cleaning | Bright, clean, ready-to-use |

| Dimensional Stability | Risk of warping and distortion | Minimal distortion, high precision |

| Post-Processing | Required (e.g., sandblasting) | Typically eliminated |

| Ideal For | Cost-sensitive, non-critical parts | High-precision, high-alloy steels, sensitive materials |

Ready to achieve flawless, high-precision hardening results?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, and specialized Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements for hardening, tempering, and more.

Contact us today to discuss how our vacuum hardening solutions can enhance your component quality, eliminate post-processing, and ensure dimensional stability for your most critical parts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity