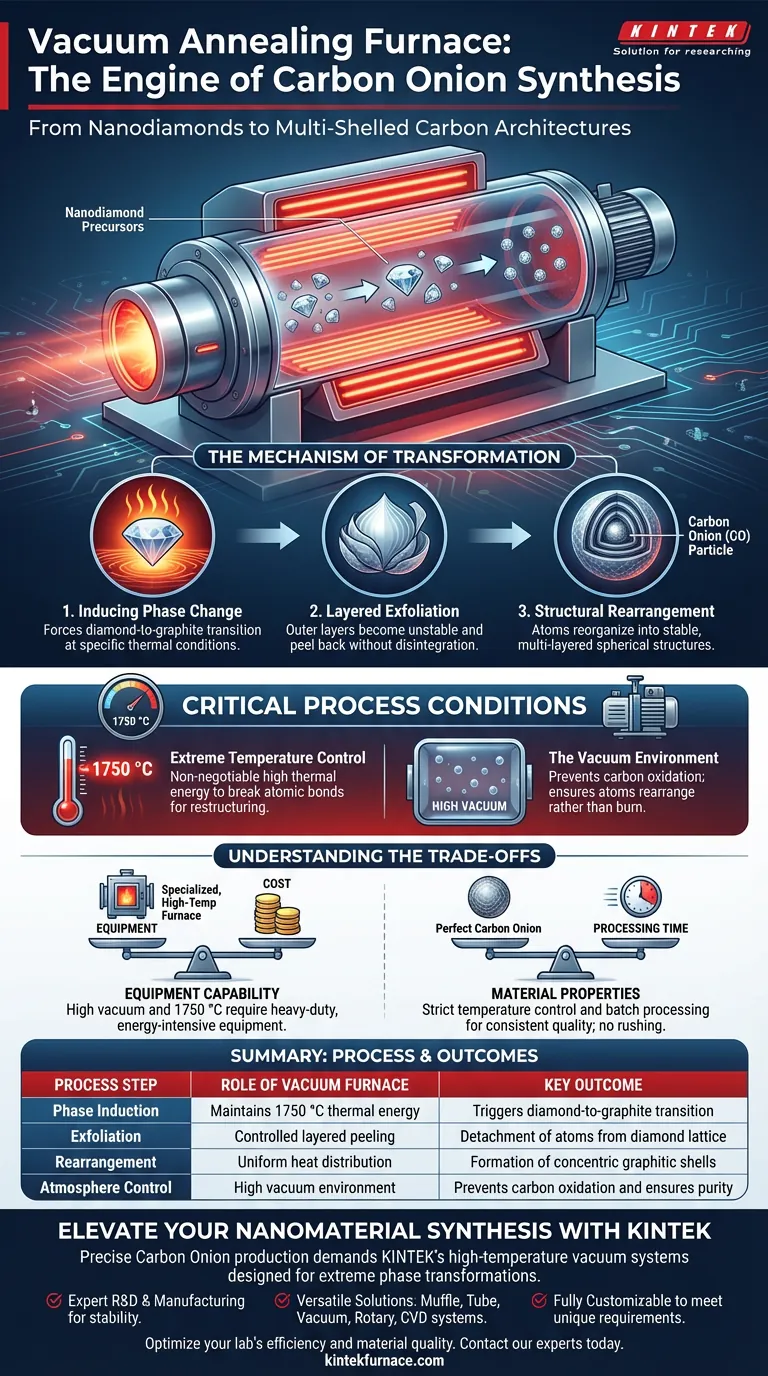

The vacuum annealing furnace serves as the critical reaction vessel for transforming nanodiamonds into Carbon Onion (CO) structures. By maintaining a strictly controlled vacuum environment at extreme temperatures of 1750 °C, the furnace drives a phase transformation that exfoliates the particle layers and rearranges them into multi-shelled, spherical carbon formations.

Core Takeaway While standard annealing is often used to soften metals, in Carbon Onion synthesis, the furnace acts as a high-precision phase reactor. It facilitates the atomic reorganization of nanodiamonds into concentric graphitic shells, unlocking unique properties like high hardness combined with exceptional lubricity.

The Mechanism of Transformation

Inducing Phase Change

The primary role of the furnace is to force a phase transformation.

It takes raw nanodiamond precursors and subjects them to specific thermal conditions. This environment causes the outer layers of the diamond structure to become unstable and shift.

Layered Exfoliation

Under these precise conditions, the particles undergo layered exfoliation.

The atomic structure essentially "peels" back. The furnace's controlled heat allows these atoms to detach from their rigid diamond lattice without disintegrating the material entirely.

Structural Rearrangement

Once exfoliated, the carbon atoms require a stable environment to settle into a new form.

The furnace facilitates the rearrangement of these particles into concentric spheres. This results in the "onion-like" multi-layered structure that defines Carbon Onion particles.

Critical Process Conditions

Extreme Temperature Control

The synthesis requires temperatures significantly higher than standard metal treatments.

The furnace must maintain a stable temperature of 1750 °C. This high thermal energy is non-negotiable for breaking the specific atomic bonds in nanodiamonds to allow for restructuring.

The Vacuum Environment

Conducting this process in a vacuum is essential for purity.

While the furnace provides uniform heating—a general characteristic of annealing equipment—the vacuum prevents oxidation. At 1750 °C, carbon would instantly burn up in the presence of oxygen; the vacuum ensures the carbon atoms rearrange rather than react.

Understanding the Trade-offs

Equipment Capability vs. Cost

Achieving 1750 °C in a high vacuum requires specialized, heavy-duty equipment.

Standard annealing furnaces used for metals (often operating at lower temperatures for stress relief) are insufficient. This makes the synthesis of Carbon Onions an energy-intensive and equipment-dependent process.

Material Properties vs. Processing Time

The process utilizes a strict temperature control program.

This implies a batch-style processing timeline. You cannot rush the heating or cooling cycles without risking thermal shock or incomplete phase transformation, which can lead to inconsistent particle sizes or structural defects.

Making the Right Choice for Your Goal

Application-Specific Recommendations

The properties of your final Carbon Onion material depend heavily on the precision of your furnace operations.

- If your primary focus is Lubrication: Ensure your furnace program prioritizes a long, stable hold time at peak temperature to ensure perfectly spherical, multi-layered shells that roll easily.

- If your primary focus is Hardness: Focus on the cooling rate control to lock in the structural integrity of the newly formed carbon layers without re-inducing stress.

The vacuum annealing furnace is not just a heater; it is the precise instrument that dictates the structural integrity and performance of the final Carbon Onion nanomaterial.

Summary Table:

| Process Step | Role of Vacuum Furnace | Key Outcome |

|---|---|---|

| Phase Induction | Maintains 1750 °C thermal energy | Triggers diamond-to-graphite transition |

| Exfoliation | Controlled layered peeling | Detachment of atoms from diamond lattice |

| Rearrangement | Uniform heat distribution | Formation of concentric graphitic shells |

| Atmosphere Control | High vacuum environment | Prevents carbon oxidation and ensures purity |

Elevate Your Nanomaterial Synthesis with KINTEK

Precise Carbon Onion production demands equipment that can withstand extreme 1750 °C environments without compromising structural integrity. KINTEK provides industry-leading high-temperature vacuum systems designed specifically for advanced phase transformations.

Why choose KINTEK?

- Expert R&D & Manufacturing: Our furnaces are built for stability and extreme thermal precision.

- Versatile Solutions: From Muffle and Tube furnaces to specialized Vacuum, Rotary, and CVD systems.

- Fully Customizable: We tailor our lab high-temp equipment to meet your unique nanotech or metallurgical requirements.

Ready to optimize your lab’s efficiency and material quality? Contact our experts today to find the perfect furnace for your research.

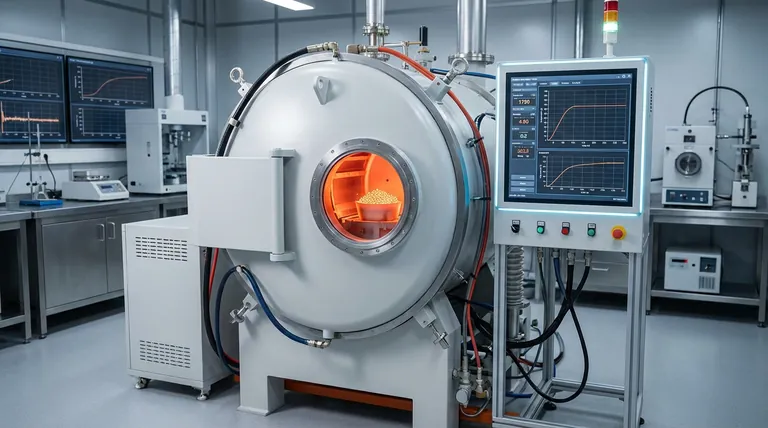

Visual Guide

References

- Timothy MacLucas, Frank Mücklich. Combining Carbon Nanoparticle Coatings and Laser Surface Texturing for Enhanced Lubricity Under High Loads. DOI: 10.1007/s11249-024-01837-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does the heating mechanism of an SPS furnace benefit CNT copper composites? Preserve Nanostructures with Rapid Heat

- How are vacuum coating furnaces applied in the semiconductor and electronic components industry? Essential for High-Purity Electronics

- What other applications do vacuum furnaces have? Unlock Advanced Material Processing Across Industries

- How is temperature controlled in a vacuum heat treatment furnace? Achieve Precision and Uniformity

- How can manufacturers select the appropriate sintering furnace for their needs? Optimize Your Production with the Right Equipment

- In what ways do customized vacuum furnaces optimize the production process? Boost Efficiency & Quality

- Why is the development of high-temperature vacuum equipment and processes increasingly important? Unlock Purity and Performance in Materials

- What key considerations should purchasers keep in mind when selecting a vacuum furnace? Expert Tips for Optimal Performance