At its core, the development of high-temperature vacuum equipment is critical because it allows for the creation and processing of advanced materials that are impossible to produce in a normal atmosphere. By removing reactive gases like oxygen, these processes enable unprecedented levels of material purity, structural integrity, and performance consistency, which are essential for industries from aerospace to medical implants.

Combining high heat with a vacuum is not just an incremental improvement; it is a fundamental shift in materials processing. It creates an ultra-pure environment that prevents contamination and unwanted chemical reactions, unlocking the true potential of high-performance metals, ceramics, and alloys.

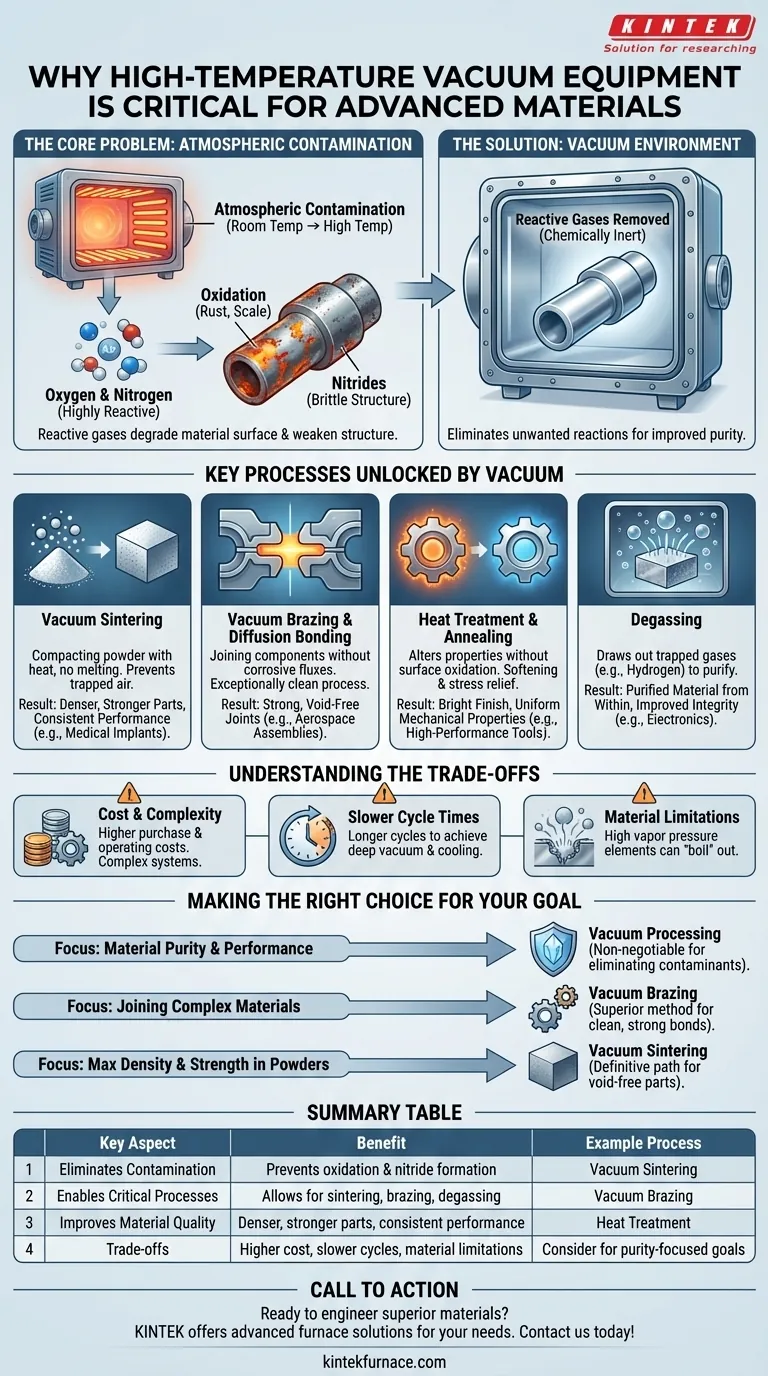

The Fundamental Problem: Atmospheric Contamination

At room temperature, the air around us is relatively benign. But when you heat materials to hundreds or thousands of degrees for manufacturing, the gases in our atmosphere—primarily nitrogen and oxygen—become highly reactive and aggressive.

The Role of Oxygen and Nitrogen

Oxygen is the primary driver of oxidation, or rust and scaling, on the surface of metals. At high temperatures, this process accelerates dramatically, degrading the material's surface, weakening its structure, and altering its properties.

Similarly, nitrogen can react with certain metals to form nitrides. While sometimes intentional (in a process called nitriding), unwanted nitride formation can make materials brittle and unreliable.

Eliminating Unwanted Reactions

A vacuum furnace removes these reactive gases. This creates a chemically inert environment, ensuring that the only reactions that occur are the ones you intend. This control is the key to achieving improved material quality.

This clean environment allows for processes like sintering and brazing to occur without the formation of oxide layers, which would otherwise inhibit proper bonding and weaken the final product.

Key Processes Unlocked by High-Temperature Vacuums

Removing the atmosphere enables several critical industrial processes that are essential for modern technology. Each one relies on the purity that a vacuum provides.

Vacuum Sintering

Sintering is the process of compacting and forming a solid mass of material from powder using heat—without melting it to the point of liquefaction.

Vacuum sintering prevents air from being trapped between the powder particles. This results in parts that are denser, stronger, and have higher performance consistency compared to those sintered in an atmosphere. This is vital for producing hardmetals, ceramics, and components for medical implants.

Vacuum Brazing and Diffusion Bonding

Brazing joins two components using a filler metal. In a vacuum, the process is exceptionally clean, creating strong, void-free joints without the need for corrosive fluxes.

Vacuum brazing is essential for creating complex assemblies in aerospace, such as fuel lines and turbine components, where joint failure would be catastrophic.

Heat Treatment and Annealing

Heat treatment alters a material's physical and sometimes chemical properties. When done in a vacuum, processes like annealing (softening and relieving stress) can be performed without causing any surface oxidation.

This leaves the component with a bright, clean finish and ensures its mechanical properties are uniform throughout, a requirement for high-performance gears, tools, and structural components.

Degassing

Many materials contain trapped gases, like hydrogen, which can compromise their structural integrity or electrical properties. Heating the material in a vacuum, or vacuum degassing, draws these trapped gases out, purifying the material from within. This is critical for materials used in electronics and high-purity metal production.

Understanding the Trade-offs

While powerful, high-temperature vacuum processing is not a universal solution. It involves clear and significant trade-offs that must be considered.

The Cost and Complexity

Vacuum furnaces are significantly more expensive to purchase, operate, and maintain than their atmospheric counterparts. The systems require complex pumping mechanisms, seals, and instrumentation to achieve and hold a low-pressure environment.

Slower Cycle Times

Achieving a deep vacuum takes time, as does cooling the workload afterward since a vacuum is a poor conductor of heat. This leads to longer overall cycle times compared to atmospheric furnaces, which can impact production throughput.

Material Limitations (Vapor Pressure)

Some elements have a high vapor pressure, meaning they tend to turn into a gas at high temperatures, especially in a vacuum. This can be a problem when processing alloys containing volatile elements like zinc, manganese, or cadmium, which can "boil" out of the material.

Making the Right Choice for Your Goal

The decision to use a high-temperature vacuum process hinges entirely on the final properties your material must have.

- If your primary focus is material purity and performance: Vacuum processing is non-negotiable for eliminating contaminants that degrade mechanical, electrical, or chemical properties.

- If your primary focus is joining complex or dissimilar materials: Vacuum brazing is the superior method for creating clean, flux-free, and exceptionally strong bonds.

- If your primary focus is achieving maximum density and strength in powdered materials: Vacuum sintering is the definitive path to producing superior, void-free parts from metal and ceramic powders.

Mastering high-temperature vacuum processing is how we move from simply making materials to truly engineering them.

Summary Table:

| Key Aspect | Benefit | Example Process |

|---|---|---|

| Eliminates Contamination | Prevents oxidation and nitride formation, ensuring material purity | Vacuum Sintering |

| Enables Critical Processes | Allows for sintering, brazing, and degassing without unwanted reactions | Vacuum Brazing |

| Improves Material Quality | Results in denser, stronger parts with consistent performance | Heat Treatment |

| Trade-offs | Higher cost, slower cycles, material limitations | Consider for purity-focused goals |

Ready to engineer superior materials with high-temperature vacuum solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization capabilities. Whether you're in aerospace, medical implants, or electronics, we help you achieve unprecedented purity and performance. Contact us today to discuss how we can support your material processing goals!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density