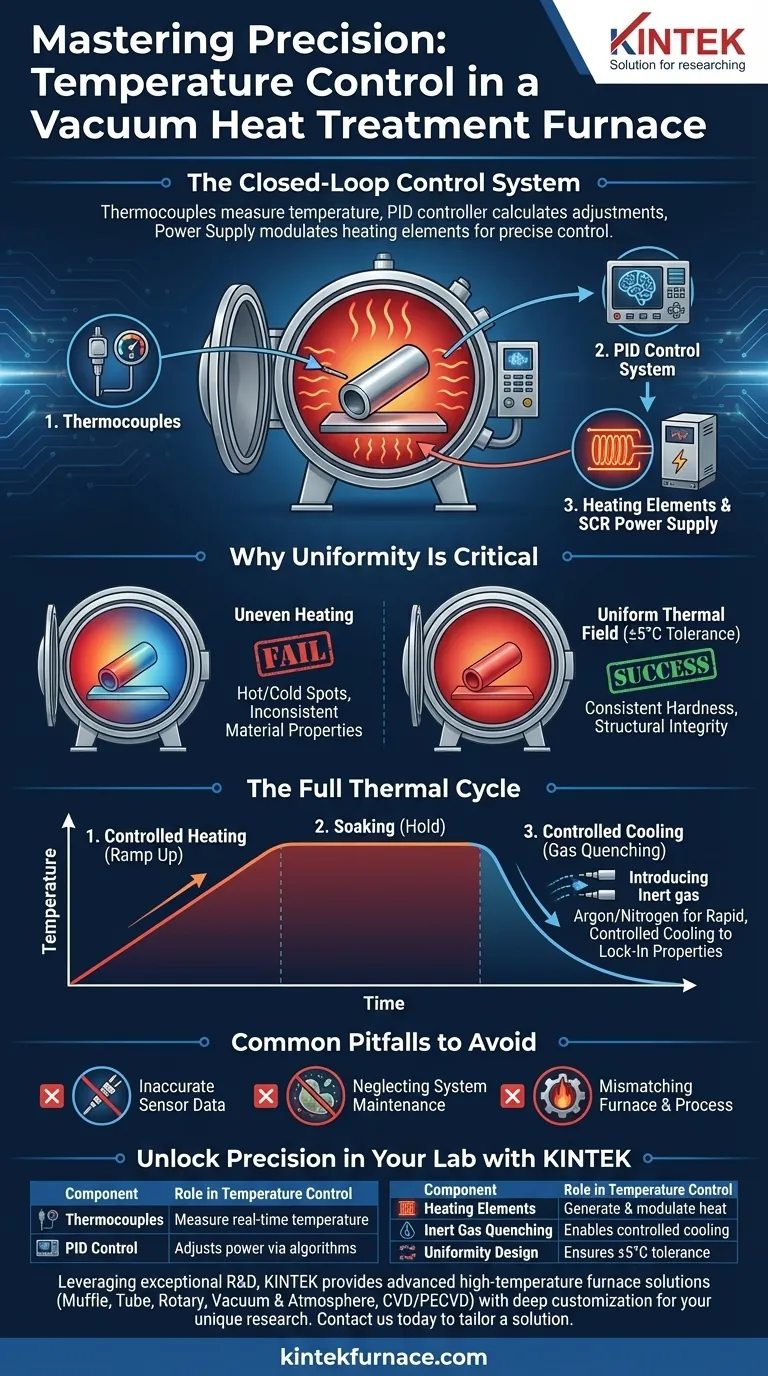

In short, temperature control in a vacuum heat treatment furnace is achieved through a closed-loop system. High-precision sensors called thermocouples constantly measure the temperature inside the chamber, and an advanced control system uses this data to precisely adjust the power supplied to the heating elements, ensuring the target temperature is maintained with exceptional accuracy and uniformity.

The core challenge in vacuum heat treatment is not just reaching a specific temperature, but achieving it uniformly across the entire workpiece without contamination. This requires a sophisticated synergy between the vacuum environment, which prevents oxidation, and an electronic control system that manages the entire thermal cycle—from heating to cooling—with extreme precision.

The Core Components of Temperature Control

A vacuum furnace's temperature control is an active, intelligent process. It relies on three key components working in constant communication to manage the energy within the system.

The Sensor: Thermocouples

Thermocouples are the "eyes" of the system. These robust sensors are strategically placed within the furnace's hot zone to provide real-time temperature readings.

Their accuracy and placement are critical. The control system is only as good as the data it receives from these sensors.

The Brain: Advanced Control Systems (PID)

The furnace's control panel is its brain. It typically uses a PID (Proportional-Integral-Derivative) controller, a sophisticated algorithm that does more than just turn the heat on and off.

A PID controller constantly calculates the error between the desired temperature (setpoint) and the actual temperature, adjusting power to not only correct current deviations but also anticipate and prevent future ones. This ensures a highly stable thermal environment.

The Muscle: Heating Elements and Power Supply

The heating elements are the components that generate the heat. The control system modulates the energy they receive via a device like an SCR (Silicon-Controlled Rectifier) Power Supply.

This allows for incredibly fine, stepless adjustments to the power output, avoiding the crude fluctuations of simple on/off control and enabling smooth, precise temperature ramps and soaks.

Why Uniformity Is as Critical as Accuracy

Reaching the correct temperature is only half the battle. If that temperature is not consistent throughout the heating zone, the treatment will fail.

The Problem of Hot and Cold Spots

Uneven heating means different parts of a component undergo different metallurgical transformations. This results in inconsistent hardness, brittleness, or internal stresses, compromising the integrity of the final product.

Achieving a Uniform Thermal Field

Vacuum furnaces are engineered to deliver a highly uniform temperature field, often with a tolerance as tight as +/- 5°C across a large volume.

This is achieved through careful design of the heating element layout and the use of control systems that can manage single or multiple heating zones to ensure even thermal radiation reaches the entire workpiece.

The Full Thermal Cycle: Heating and Cooling

Effective temperature control manages the entire process, from the initial ramp-up to the final cooling phase. Each stage is critical for achieving the desired material properties.

Controlled Heating and Soaking

The control system manages the rate of temperature increase (the ramp) to prevent thermal shock to the material. It then holds the material at a specific temperature (the soak) for a precise duration to allow the desired metallurgical changes to occur.

Controlled Cooling (Quenching)

The cooling phase is just as important as the heating phase. The rate of cooling determines the final microstructure and properties of the material.

To achieve rapid and controlled cooling, the furnace backfills the vacuum chamber with a high-purity inert gas, such as argon or nitrogen. This gas transfers heat away from the part in a process known as gas quenching, "locking in" the properties developed during the heat soak.

Common Pitfalls to Avoid

Even the most advanced furnace relies on proper operation and maintenance. Overlooking these factors can undermine the system's precision.

Inaccurate Sensor Data

A thermocouple's accuracy can degrade over time or if it's improperly placed. A sensor reading from the edge of the chamber may not represent the true temperature of the part in the center. Regular calibration and verification are essential.

Neglecting System Maintenance

The performance of a vacuum furnace is directly tied to its condition. A contaminated chamber, leaking seals, or aging heating elements will degrade temperature uniformity and control.

A rigorous maintenance schedule for cleaning the chamber, checking seals, and inspecting heating elements is non-negotiable for reliable and repeatable results.

Mismatching Furnace and Process

Furnaces are designed for specific temperature ranges, such as 1300°C or 1650°C. Attempting to run a process that exceeds a furnace's maximum rated temperature or uniformity specifications will lead to equipment damage and failed parts.

Applying This to Your Process

Your specific goal determines which aspect of temperature control you should prioritize.

- If your primary focus is process repeatability: The key is a system with tight PID control, SCR power regulation, and documented temperature uniformity specifications.

- If your primary focus is treating large or complex parts: Prioritize furnaces with multiple, independently controlled heating zones to guarantee a uniform thermal field across the entire workload.

- If your primary focus is operational reliability: A rigorous, preventative maintenance schedule for thermocouples, seals, and heating elements is the most critical factor for long-term success.

Understanding these principles of control transforms the furnace from a simple oven into a precision instrument for engineering materials.

Summary Table:

| Component | Role in Temperature Control |

|---|---|

| Thermocouples | Measure real-time temperature with high precision |

| PID Control System | Adjusts power using algorithms for stable thermal cycles |

| Heating Elements & Power Supply | Generate and modulate heat for uniform distribution |

| Inert Gas Quenching | Enables controlled cooling for material properties |

| Uniformity Design | Ensures +/- 5°C tolerance across the chamber |

Unlock Precision in Your Lab with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you need enhanced process repeatability, uniform heating for complex parts, or reliable long-term performance, our expertise in temperature control ensures optimal results. Contact us today to discuss how we can tailor a solution for your specific heat treatment challenges!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today