Customized vacuum furnaces optimize production by precisely aligning the equipment's design with the specific metallurgical requirements of a component or process. Instead of using a general-purpose system, a custom furnace integrates tailored heating, cooling, and control systems to eliminate process steps, reduce energy waste, and guarantee repeatable, high-quality results for a specific application.

The core advantage of a custom vacuum furnace is not about adding features, but about eliminating compromise. While standard furnaces provide versatility, customization delivers peak performance, efficiency, and quality for a single, well-defined production goal.

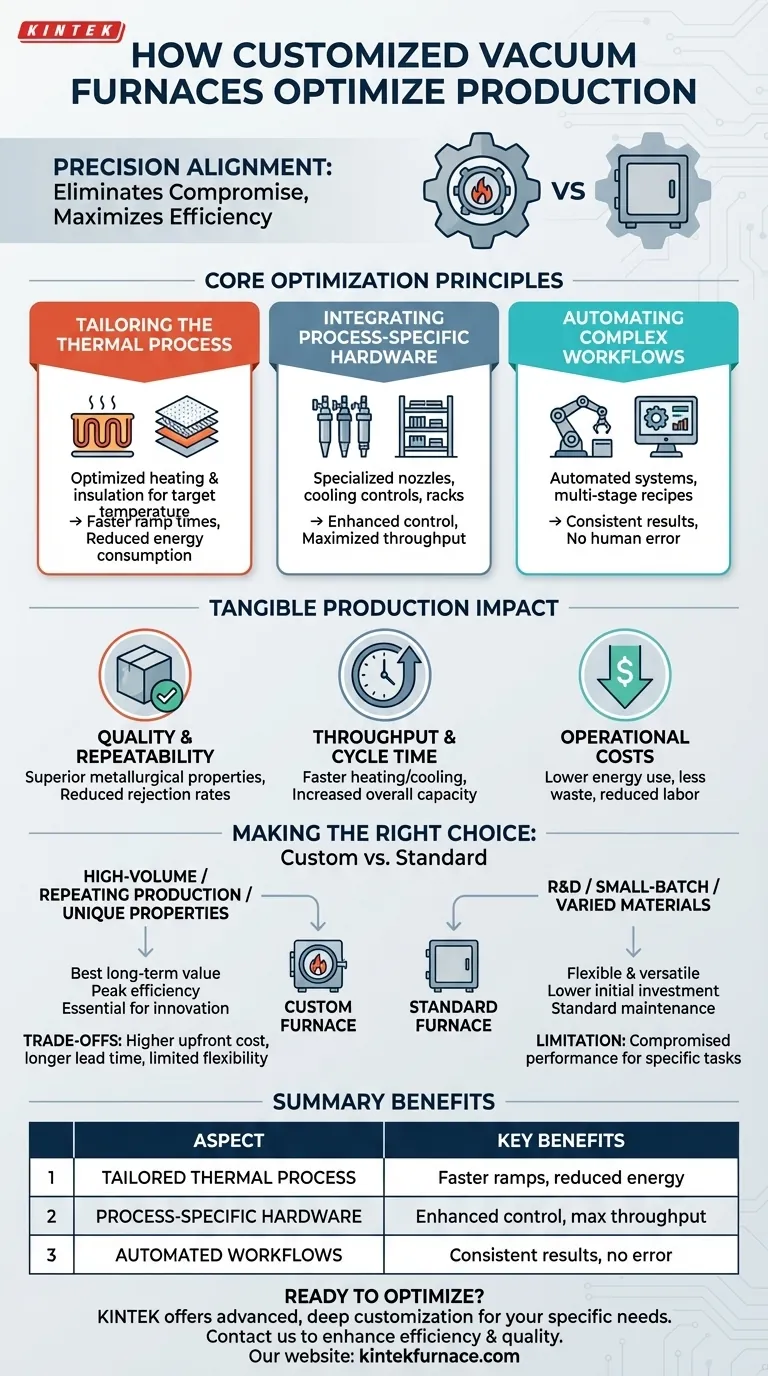

Beyond 'One Size Fits All': Core Principles of Optimization

A standard furnace is designed to perform many tasks adequately. A custom furnace is engineered to perform a specific task perfectly. This optimization is achieved through several key principles.

Tailoring the Thermal Process

Standard furnaces are built to handle a wide temperature range, often from 800 °C to 3,000 °C. However, most production processes operate within a much narrower band.

Customization involves selecting heating elements, chamber dimensions, and efficient insulation materials that are optimized for your target temperature. This ensures faster ramp times and minimizes heat loss, directly reducing energy consumption and operational costs.

Integrating Process-Specific Hardware

The most significant gains come from integrating hardware designed for a specific task. A generic furnace cannot match the performance of a purpose-built system.

For example, a furnace customized for vacuum quenching may include high-pressure gas nozzles (up to 20 bar) for rapid, uniform cooling. It might also feature advanced cooling rate controls to precisely manage the martensitic transformation in tool steels, a level of control that is impossible with standard equipment.

Other hardware customizations include double chambers for oil quenching or specialized racks designed to maximize the throughput of a specific part.

Automating Complex Workflows

Modern production demands absolute consistency. Customization allows for the design of automated control systems that manage the entire production cycle without operator intervention.

These systems can execute complex, multi-stage recipes for processes like vacuum annealing, sintering, or tempering. By automating the heating, soaking, and cooling sequences, you eliminate the risk of human error, ensure every batch is identical, and free up skilled labor for other tasks.

The Tangible Impact on Production Metrics

Aligning the furnace design with the production goal delivers measurable improvements across key performance indicators.

Enhancing Part Quality and Repeatability

By precisely controlling every variable—from temperature uniformity to cooling rate—a custom furnace produces parts with superior and consistent metallurgical properties. This reduces rejection rates and ensures that the final product meets stringent quality standards every time.

Maximizing Throughput and Reducing Cycle Time

An optimized thermal process means faster heating and cooling. Automated sequences eliminate delays between steps. Together, these factors significantly shorten the total cycle time per batch. Over the life of the furnace, this increased throughput has a massive impact on overall production capacity.

Slashing Operational Costs

The benefits of customization directly translate to a lower cost per part. This is achieved by reducing energy consumption, eliminating waste from rejected parts, and lowering the labor costs associated with manual furnace operation.

Understanding the Trade-offs: Custom vs. Standard

While powerful, a custom solution is not always the right choice. Understanding the trade-offs is critical for making an informed investment.

The Upfront Investment

A custom-engineered furnace will have a higher initial purchase price and a longer lead time than an off-the-shelf model. The decision must be justified by the long-term gains in efficiency, quality, and throughput.

The Lack of Flexibility

The primary strength of a custom furnace is also its main limitation. A system highly optimized for one specific process (like quenching small parts) will be inefficient or unusable for a completely different task (like sintering large components).

Specialized Maintenance

Custom components, such as unique nozzle configurations or non-standard heating elements, may require specialized spare parts and maintenance procedures. This can be a factor if your maintenance team is accustomed to working only with standard equipment.

Making the Right Choice for Your Application

The decision to invest in a standard or custom vacuum furnace should be driven by your primary production objective.

- If your primary focus is high-volume, repeatable production of a specific part: A custom furnace is almost always the most cost-effective solution in the long run due to its superior efficiency and throughput.

- If your primary focus is research, development, or small-batch jobs with varied materials: A versatile, standard furnace provides the necessary flexibility to explore different processes without over-investing in a single capability.

- If your primary focus is achieving unique metallurgical properties that standard equipment cannot: Customization is not an option but a necessity to engineer the exact thermal conditions required for your innovation.

Ultimately, choosing a custom furnace is a strategic decision to align your equipment's capabilities directly with your most critical production goals.

Summary Table:

| Optimization Aspect | Key Benefits |

|---|---|

| Tailored Thermal Process | Faster ramp times, reduced energy consumption |

| Process-Specific Hardware | Enhanced control for tasks like vacuum quenching |

| Automated Workflows | Consistent results, reduced human error |

| Impact on Production | Higher throughput, lower costs, improved quality |

Ready to optimize your production with a custom vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Contact us today to discuss how we can enhance your efficiency and quality!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today