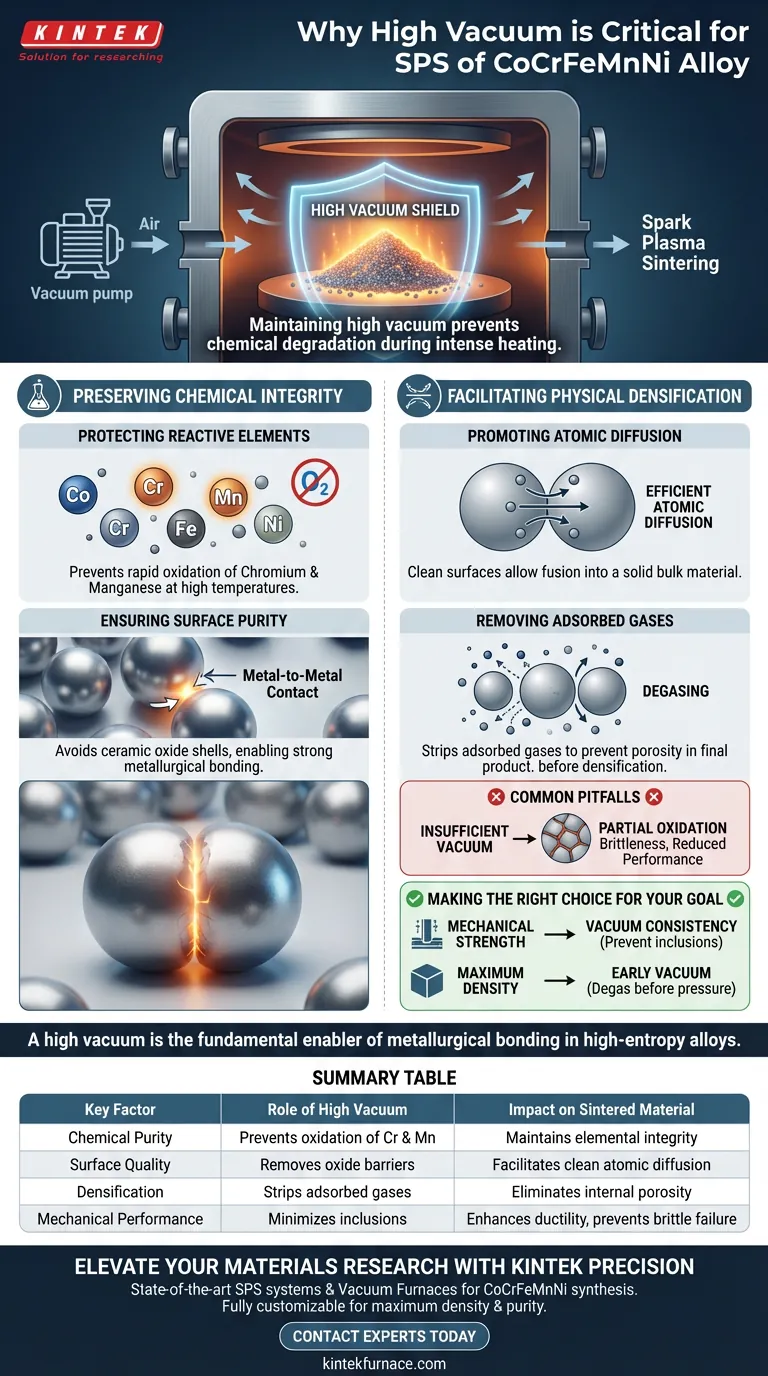

Maintaining a high vacuum is critical to prevent the chemical degradation of CoCrFeMnNi alloy powders during the intense heating of Spark Plasma Sintering (SPS). It specifically prevents the oxidation of reactive elements like chromium and manganese, ensuring the powder particles remain pure. This environment is a prerequisite for creating the clean surfaces necessary for effective atomic diffusion and high material density.

The vacuum acts as a critical shield for the alloy's purity, preventing the formation of oxide layers that inhibit particle bonding. Without this isolation, the high reactivity of the alloy's components at sintering temperatures would compromise both the structural integrity and the density of the material.

Preserving Chemical Integrity

Protecting Reactive Elements

The CoCrFeMnNi alloy contains elements that are chemically active and highly sensitive to oxygen. Chromium and manganese, in particular, are prone to rapid oxidation when exposed to high temperatures in non-vacuum environments. A high vacuum effectively excludes active gases from the chamber, neutralizing the risk of these elements degrading into oxides.

Ensuring Surface Purity

Oxidation creates a ceramic-like shell around metal powder particles. This shell acts as a barrier, preventing the metal-to-metal contact required for a strong metallurgical bond. By maintaining a high vacuum, you ensure the particle surfaces remain metallic and clean throughout the heating process.

Facilitating Physical Densification

Promoting Atomic Diffusion

SPS relies on atomic diffusion to fuse powder particles into a solid bulk material. This diffusion occurs most efficiently when particle surfaces are free of contaminants and oxides. The vacuum environment facilitates this atomic diffusion contact, allowing the material to achieve a homogenous structure.

Removing Adsorbed Gases

Powder particles often have gases adsorbed onto their surfaces or trapped within the gaps between them. If these gases are not removed prior to densification, they can become trapped inside the final product, leading to porosity. The vacuum assists in stripping these adsorbed gases, significantly enhancing the density of the sintered body.

Common Pitfalls to Avoid

While the necessity of a vacuum is clear, the quality of that vacuum is equally important. Insufficient vacuum levels (poor pressure) can lead to "partial oxidation," where micro-scale oxide inclusions form at grain boundaries. This results in a material that may look dense but suffers from brittleness and reduced mechanical performance. Furthermore, failing to maintain the vacuum during the cooling phase can result in surface oxidation of the newly formed bulk material.

Making the Right Choice for Your Goal

To maximize the quality of your CoCrFeMnNi alloy, apply the vacuum protocols based on your specific sintering objectives:

- If your primary focus is Mechanical Strength: Prioritize vacuum consistency to prevent oxide formation on Manganese and Chromium, as oxide inclusions will act as crack initiation sites.

- If your primary focus is Maximum Density: Ensure the vacuum is applied early in the cycle to fully degas the powder gaps and remove adsorbed layers before high pressure seals the pores.

A high vacuum is not merely a process variable; it is the fundamental enabler of metallurgical bonding in high-entropy alloys.

Summary Table:

| Key Factor | Role of High Vacuum | Impact on Sintered Material |

|---|---|---|

| Chemical Purity | Prevents oxidation of Cr & Mn | Maintains elemental integrity & metallic surfaces |

| Surface Quality | Removes oxide barriers | Facilitates clean metal-to-metal atomic diffusion |

| Densification | Strips adsorbed gases | Eliminates internal porosity for maximum density |

| Mechanical Performance | Minimizes grain boundary inclusions | Enhances ductility and prevents brittle failure |

Elevate Your Materials Research with KINTEK Precision

Don't let oxidation compromise your High-Entropy Alloy research. KINTEK provides state-of-the-art Spark Plasma Sintering (SPS) systems and specialized Vacuum Furnaces engineered for the rigorous demands of CoCrFeMnNi synthesis.

Backed by expert R&D and manufacturing, our systems—including Muffle, Tube, Rotary, and CVD options—are fully customizable to ensure your laboratory achieves maximum material density and chemical purity.

Ready to optimize your sintering process? Contact our technical experts today to find the perfect high-temp solution for your unique research needs.

Visual Guide

References

- Anna Kopeć-Surzyn, M. Madej. Influence of Tooling on the Properties of the Surface Layer in HEA Alloy Sinters Produced by the SPS Method. DOI: 10.3390/coatings14020186

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What factors are important in vacuum brazing? Achieve Flawless Joints with Precision Control

- Why is a vacuum drying oven essential for High-Entropy Marimo (HE-MARIMO)? Protect Structural Integrity

- What are the two common hot zone configurations in vertical vacuum furnaces? Compare Graphite vs. All-Metal

- What core process conditions does an industrial vacuum brazing furnace provide for joining X37CrMoV5-1 tool steel?

- What function does a high vacuum sintering furnace serve in Ti6Al4V densification? Achieve Superior Material Purity

- How do computer-controlled systems enhance vacuum furnace operations? Achieve Precision and Repeatability in Heat Treatment

- What is vacuum annealing and what benefits does it provide? Achieve Superior Material Properties and Pristine Surfaces

- What is vacuum brazing and why is it important in modern manufacturing? Discover Superior, Clean Metal Joining