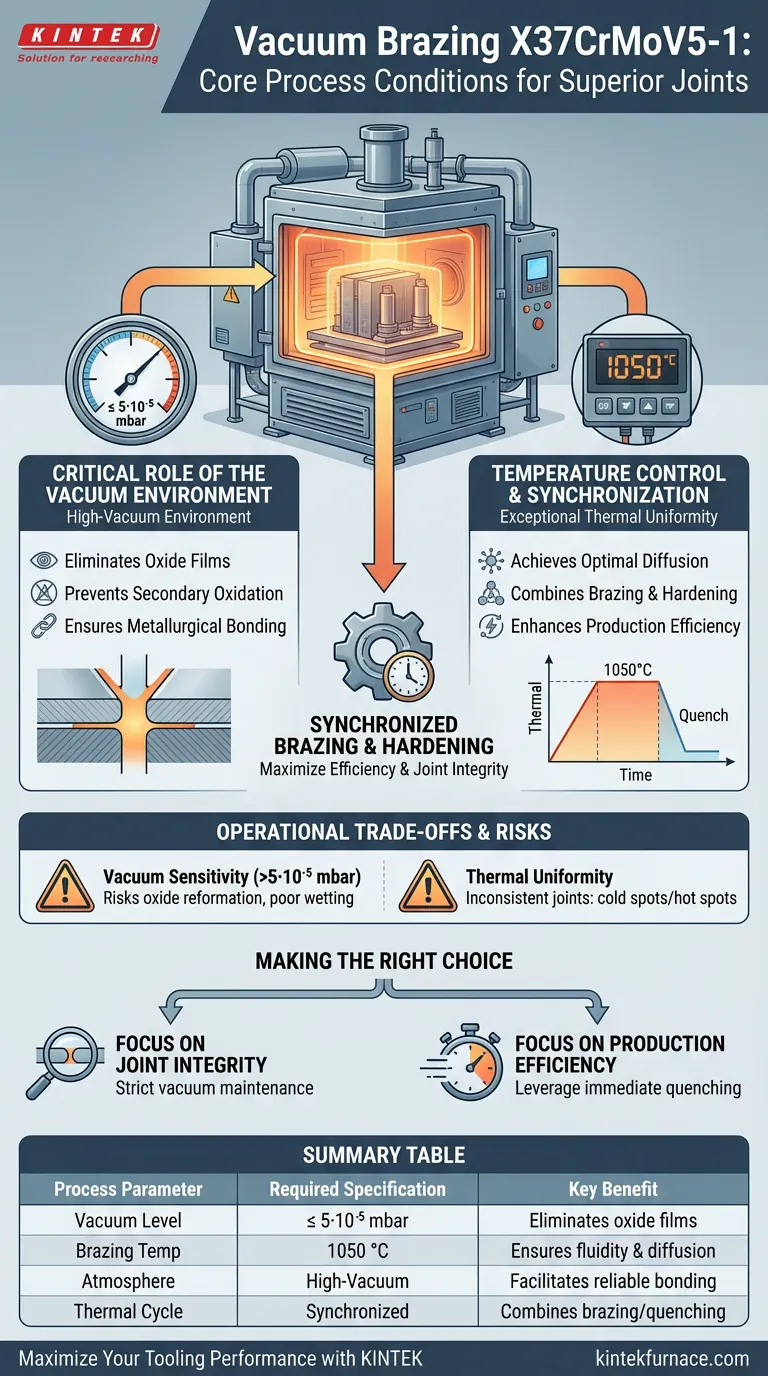

An industrial vacuum brazing furnace fundamentally provides a high-vacuum environment, typically maintained at ≤ 5∙10⁻⁵ mbar, paired with a heating space capable of exceptional thermal uniformity.

For X37CrMoV5-1 hot-work tool steel, these conditions allow the process to reach 1050 °C, facilitating full spreading of the filler metal and deep diffusion with the base material while preventing oxidation.

By maintaining precise pressure and temperature control, the furnace allows you to synchronize the brazing process with the steel’s quenching and hardening cycles, simultaneously maximizing production efficiency and joint integrity.

The Critical Role of the Vacuum Environment

Eliminating Surface Impurities

The furnace creates a "clean" heating environment by maintaining a high vacuum. This removes existing oxide films from the surface of the stainless steel, which are barriers to successful joining.

Preventing Secondary Oxidation

Beyond removing current oxides, the vacuum level (approaching 10⁻⁶ mbar in high-performance contexts) prevents secondary oxidation of both the base material and the brazing filler metal.

Ensuring Metallurgical Bonding

This oxide-free state is the essential physical condition required for the filler metal to wet the surface properly. It ensures the formation of a dense, reliable metallurgical bond rather than a superficial adhesion.

Temperature Control and Process Synchronization

Achieving Optimal Diffusion

The furnace provides a uniform temperature distribution at 1050 °C. At this specific thermal plateau, the brazing filler metal achieves the necessary fluidity to fully spread and undergo diffusion with the X37CrMoV5-1 substrate.

Combining Brazing and Hardening

A distinct advantage of this industrial process is the ability to combine steps. The precise thermal controls allow the brazing process to be synchronized with the quenching and hardening of the tool steel.

Enhancing Production Efficiency

By merging these thermal cycles, you eliminate the need for separate reheating steps. This preserves the dimensional stability of the tool steel while significantly reducing overall processing time.

Operational Trade-offs and Risks

Vacuum Sensitivity

The process is intolerant of vacuum leaks or pump degradation. If the pressure rises above the 5∙10⁻⁵ mbar threshold, oxide layers may reform immediately, preventing the filler metal from wetting the steel.

Thermal Uniformity Requirements

While 1050 °C is the target, deviations in temperature uniformity can lead to inconsistent joint strength. Cold spots result in poor diffusion, while hot spots may degrade the microstructure of the X37CrMoV5-1 steel.

Making the Right Choice for Your Goal

To maximize the performance of your X37CrMoV5-1 components, align your process parameters with your specific engineering objectives:

- If your primary focus is Joint Integrity: Prioritize vacuum maintenance to ensure pressure stays strictly below 5∙10⁻⁵ mbar to guarantee complete oxide removal and optimal wetting.

- If your primary focus is Production Efficiency: Leverage the furnace's ability to perform the hardening quench immediately following the 1050 °C brazing cycle to reduce cycle times.

Success relies on balancing a pristine vacuum environment with precise thermal management to achieve a synchronized, defect-free bond.

Summary Table:

| Process Parameter | Required Specification | Key Benefit |

|---|---|---|

| Vacuum Level | ≤ 5∙10⁻⁵ mbar | Eliminates oxide films & prevents secondary oxidation |

| Brazing Temp | 1050 °C | Ensures optimal filler metal fluidity & deep diffusion |

| Atmosphere | High-Vacuum | Facilitates dense, reliable metallurgical bonding |

| Thermal Cycle | Synchronized | Combines brazing with quenching/hardening for efficiency |

Maximize Your Tooling Performance with KINTEK

Unlock the full potential of your X37CrMoV5-1 components with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, and CVD systems specifically engineered to maintain the rigorous vacuum levels and thermal uniformity required for complex brazing and hardening cycles.

Whether you need a specialized rotary furnace or a custom lab high-temp system, our equipment is customizable for your unique metallurgical needs, ensuring defect-free bonds and optimized production efficiency.

Ready to elevate your manufacturing precision? Contact KINTEK today to consult with our experts.

Visual Guide

References

- Kirsten Bobzin, M. Erck. Dissolving brittle phases in Ni-based filler metals by adding W. DOI: 10.1007/s40194-025-01981-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What materials can be used for retorts in hot wall furnaces? Choose the Right Material for Your Process

- What technical advantages do electric furnace systems offer for copper slag impoverishment? Maximize Your Metal Recovery

- What types of heat treatment processes use vacuum furnaces? Achieve Purity and Precision in Material Processing

- Can High Vacuum Melting Furnaces be customized? Tailor Precision Solutions for Your Lab

- What are graphite retorts used for in vacuum furnaces? A Guide to High-Temperature Processing

- What are the benefits of vacuum annealing on material hardness and strength? Enhance Material Integrity with Controlled Heat Treatment

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the basic structure of a vacuum furnace? Discover Its Core Components and Functions