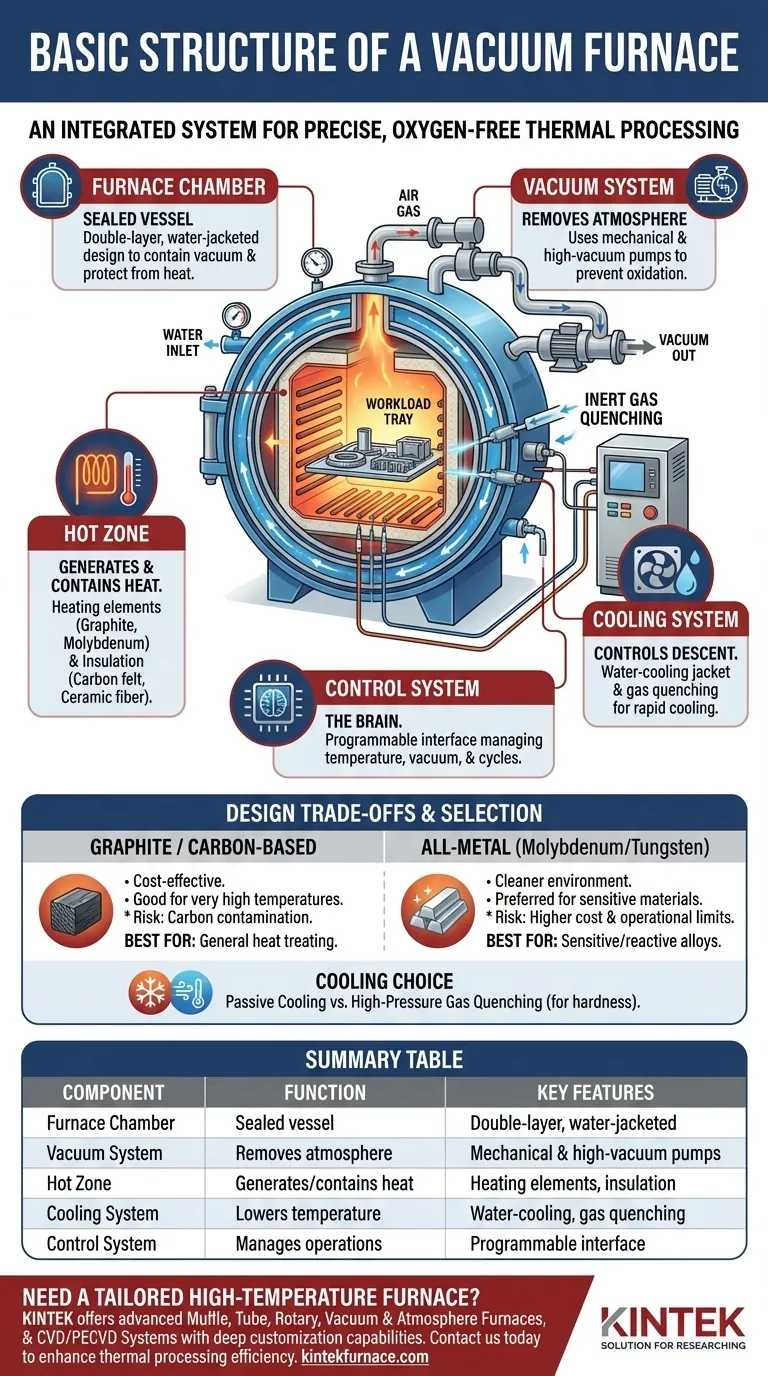

At its core, a vacuum furnace is a highly integrated system designed for thermal processing in a controlled, oxygen-free environment. Its structure consists of five primary functional groups: a sealed furnace chamber to contain the process, a vacuum system to remove the atmosphere, a hot zone to generate and contain heat, a cooling system to lower the temperature, and a control system to orchestrate every step.

A vacuum furnace's structure is designed for one primary purpose: to enable precise thermal processing in a highly controlled, contamination-free atmosphere. It is not merely a heater; it is a complete environmental control system where each component serves a critical function.

The Core Components by Function

Understanding a vacuum furnace begins with looking at its components not as a simple list of parts, but as interconnected systems working toward a common goal.

The Furnace Chamber: The Sealed Vessel

The furnace chamber, also called the vessel or shell, is the main body of the unit. It provides the physical structure and creates the sealed space necessary for creating a vacuum.

Typically constructed from high-strength steel plates, the chamber is often built with a double-layer, water-jacketed design. This internal water cooling prevents the outer shell from overheating, protecting both the equipment and operators.

The Vacuum System: Creating the Environment

This is the defining feature that separates a vacuum furnace from a standard furnace. Its sole job is to remove air and other gases from the chamber before and during the heating process.

This system usually involves a series of pumps, such as mechanical pumps for initial roughing and high-vacuum pumps (like molecular or eddy current pumps) to achieve lower pressures. By removing oxygen and other reactive gases, the system prevents oxidation and contamination of the material being processed.

The Hot Zone: Generating and Containing Heat

The "hot zone" is the heart of the furnace, where the actual heating takes place. It is composed of two key elements working in tandem.

Heating Elements

These are the components that convert electrical energy into heat. The choice of material depends on the required temperature and the process environment. Common options include graphite, molybdenum, tungsten, and specialized resistance wires.

Insulation

To protect the furnace chamber and efficiently focus energy on the workload, the hot zone is lined with insulation. Materials like high-grade carbon felt, flexible graphite paper, or ceramic fiber are used to contain the intense radiant heat.

The Cooling System: Controlling the Descent

After the heating cycle is complete, the workload must be cooled in a controlled manner. This is often as critical as the heating process itself.

One method is the water-cooling jacket on the furnace shell, which passively removes heat from the chamber. For more rapid cooling (quenching), a system injects high-pressure inert gas like nitrogen or argon through nozzles distributed around the hot zone, quickly drawing heat away from the parts.

The Control System: The Brain of the Operation

This system is the nerve center that manages every other component. It integrates temperature sensors (thermometers), vacuum gauges, and power supplies into a single, programmable interface.

The control system executes the desired heating profile, maintains the precise vacuum level, and initiates the cooling cycle at the correct time. This ensures the process is repeatable, accurate, and safe.

Understanding the Trade-offs in Furnace Design

The specific construction of a vacuum furnace involves critical choices that impact its performance, cost, and applications. There is no single "best" configuration.

Heating Element Selection

The choice between graphite and metal heating elements is a primary consideration. Graphite is cost-effective and excellent for very high temperatures, but it can be a source of carbon contamination, which is detrimental to certain alloys.

An all-metal hot zone using molybdenum or tungsten elements is "cleaner" and preferred for processing highly sensitive or reactive materials. However, these metals are more expensive and have their own operational limits.

Insulation Choices

The trade-off here mirrors the heating elements. Carbon-based insulation (like carbon felt) is common and effective but can outgas or contribute to a carbon-rich atmosphere.

Ceramic fiber insulation or metallic heat shields offer a cleaner environment but can be more fragile or significantly increase the furnace's cost. The right choice depends entirely on the chemical sensitivity of the materials being processed.

Cooling Method and Speed

A furnace designed for simple annealing may only need passive cooling. However, a furnace used for hardening tool steels requires a high-pressure gas quenching system. This adds complexity and cost, including the need for gas storage tanks, but is essential for achieving specific metallurgical properties.

Making the Right Choice for Your Goal

The optimal vacuum furnace structure is defined by its intended application. When evaluating or specifying a furnace, consider the function first.

- If your primary focus is general-purpose heat treating: A robust furnace with graphite heating elements and carbon felt insulation is a cost-effective and reliable choice.

- If your primary focus is processing highly sensitive or reactive alloys: Prioritize an all-metal hot zone (molybdenum/tungsten) and non-carbon insulation to prevent contamination.

- If your primary focus is achieving specific material hardness (e.g., tool steels): Ensure the furnace is equipped with a high-pressure inert gas quenching system for rapid, controlled cooling.

Understanding these core systems and their interplay is the key to leveraging vacuum furnace technology for any application.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Chamber | Sealed vessel for vacuum | Double-layer, water-jacketed design |

| Vacuum System | Removes air and gases | Mechanical and high-vacuum pumps |

| Hot Zone | Generates and contains heat | Heating elements (graphite, molybdenum, etc.), insulation |

| Cooling System | Lowers temperature post-heating | Water-cooling jacket, gas quenching |

| Control System | Manages operations | Programmable interface for precision |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your experimental goals—whether for general heat treating, sensitive alloys, or rapid quenching. Contact us today to enhance your thermal processing efficiency and achieve superior results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?