In short, yes. High Vacuum Melting Furnaces are not only customizable, but they are frequently engineered-to-order to meet precise material science and manufacturing requirements. This customization ensures the furnace is optimized for your specific alloys, batch sizes, and operational standards, moving it from a standard piece of equipment to a purpose-built asset.

Customization goes far beyond simple size adjustments. It involves a detailed engineering process to align the furnace's core systems—from the vacuum and heating elements to the control and safety mechanisms—with your specific application, ensuring optimal performance, purity, and operational safety.

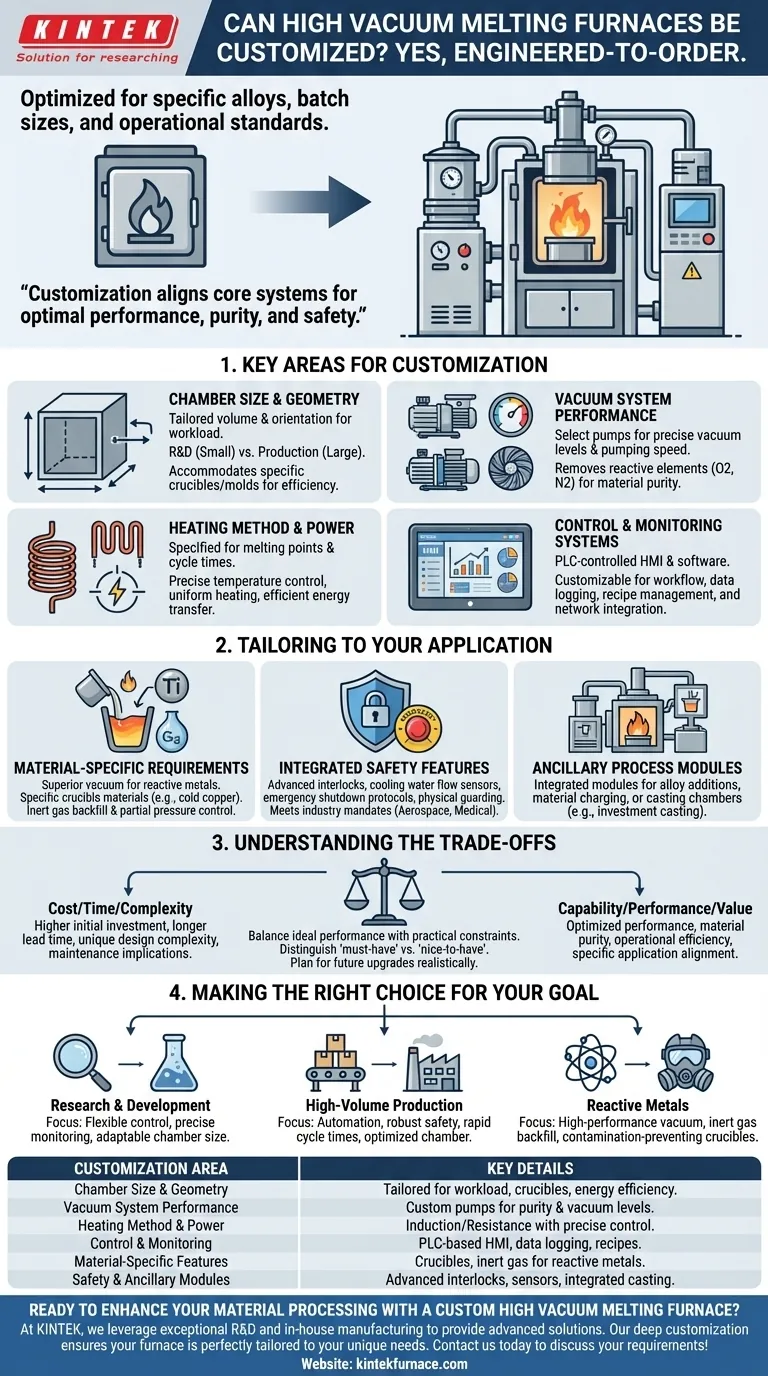

Key Areas for Customization

True customization involves a technical assessment of your process goals. A manufacturer will work with you to specify several core subsystems of the furnace to ensure it performs exactly as needed.

Chamber Size and Geometry

The most apparent customization is the vacuum chamber itself. Its volume and orientation are tailored to your workload, whether for small-scale R&D melts or large-scale industrial production.

This includes adjusting the internal dimensions to accommodate specific crucible sizes or casting molds, ensuring efficient use of space and energy.

Vacuum System Performance

The vacuum system is critical for material purity. Customization here involves selecting the right combination of pumps (e.g., rotary, diffusion, turbo-molecular) to achieve the specific vacuum level and pumping speed your materials require.

This ensures that reactive elements in the atmosphere, like oxygen and nitrogen, are removed to the necessary degree, preventing contamination of the melt.

Heating Method and Power

The heating system can be specified based on the melting points of your alloys and desired cycle times. This includes choosing between technologies like induction or resistance heating.

The power supply and coil design (for induction) are engineered to provide precise temperature control, uniform heating, and efficient energy transfer for your specific load.

Control and Monitoring Systems

Modern furnaces are PLC-controlled. The Human-Machine Interface (HMI) and software can be customized for your operational workflow, data logging requirements, and recipe management.

This allows for highly repeatable processes, quality assurance tracking, and integration with your facility's network.

Tailoring the Furnace to Your Application

Beyond core components, customization is driven by the final product. The furnace must be designed to support the unique demands of the materials you work with and the safety standards you must meet.

Material-Specific Requirements

The materials being melted dictate many design choices. For example, melting highly reactive metals like titanium requires a superior vacuum system and specific crucible materials (like a cold copper crucible) to prevent contamination.

The system can also be configured with inert gas backfill and partial pressure control, which is essential for certain advanced alloys.

Integrated Safety Features

Safety is not an afterthought; it's an integral part of the design. Standard features like overpressure and short-circuit protection can be augmented based on your facility's requirements.

Customization can include advanced interlocks, cooling water flow sensors, emergency shutdown protocols, and physical guarding to meet or exceed industry-specific safety mandates (e.g., for aerospace or medical applications).

Ancillary Process Modules

A furnace can be more than just a melting chamber. It can be customized as part of a larger system, incorporating modules for alloy additions, material charging, or integrated casting chambers for processes like investment casting.

Understanding the Trade-offs of Customization

While customization offers significant advantages, it is essential to approach it with a clear understanding of the associated trade-offs. A well-informed decision balances ideal performance with practical constraints.

Cost vs. Capability

Every custom feature adds to the initial capital investment. It is crucial to distinguish between "must-have" specifications that directly impact product quality and "nice-to-have" features that may not provide a proportional return.

Lead Time and Complexity

An engineered-to-order furnace will have a significantly longer lead time than a standard, off-the-shelf model. The unique design also adds complexity, which can have downstream implications for maintenance, spare parts, and operator training.

Future-Proofing vs. Over-Engineering

It is wise to plan for future needs, but over-specifying a furnace for hypothetical future processes can lead to unnecessary expense and complexity. The best approach is to design for your current, validated needs with a clear, realistic path for future upgrades.

Making the Right Choice for Your Goal

The optimal furnace configuration depends entirely on your primary objective. By clearly defining your goal, you can guide the customization process effectively.

- If your primary focus is research and development: Prioritize a flexible control system, precise temperature and vacuum monitoring, and a smaller, more adaptable chamber size.

- If your primary focus is high-volume production: Emphasize automation, robust safety interlocks, rapid cycle times, and a chamber optimized for your specific part geometry and batch size.

- If your primary focus is working with highly reactive metals: Specify a high-performance vacuum system, an inert gas backfill option, and crucible materials that prevent melt contamination.

A well-specified custom furnace is a strategic asset, directly enabling the quality and innovation of your final product.

Summary Table:

| Customization Area | Key Details |

|---|---|

| Chamber Size & Geometry | Tailored for workload, crucible sizes, and energy efficiency |

| Vacuum System Performance | Custom pumps for specific vacuum levels and material purity |

| Heating Method & Power | Induction or resistance heating with precise temperature control |

| Control & Monitoring | PLC-based HMI, data logging, and recipe management |

| Material-Specific Features | Crucible materials, inert gas backfill for reactive metals |

| Safety & Ancillary Modules | Advanced interlocks, cooling sensors, and integrated casting |

Ready to enhance your material processing with a custom high vacuum melting furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your furnace is perfectly tailored to your unique experimental needs, boosting purity, safety, and efficiency. Contact us today to discuss your requirements and discover how we can support your goals in research, production, or handling reactive materials!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications