In material science and manufacturing, vacuum annealing is a specialized heat treatment process where a material is heated to a specific temperature and then cooled in a controlled manner, all within a high-vacuum environment. This process is used to relieve internal stresses, increase ductility and toughness, and improve other properties without causing surface oxidation or contamination. The result is a part with superior material characteristics and a pristine surface finish.

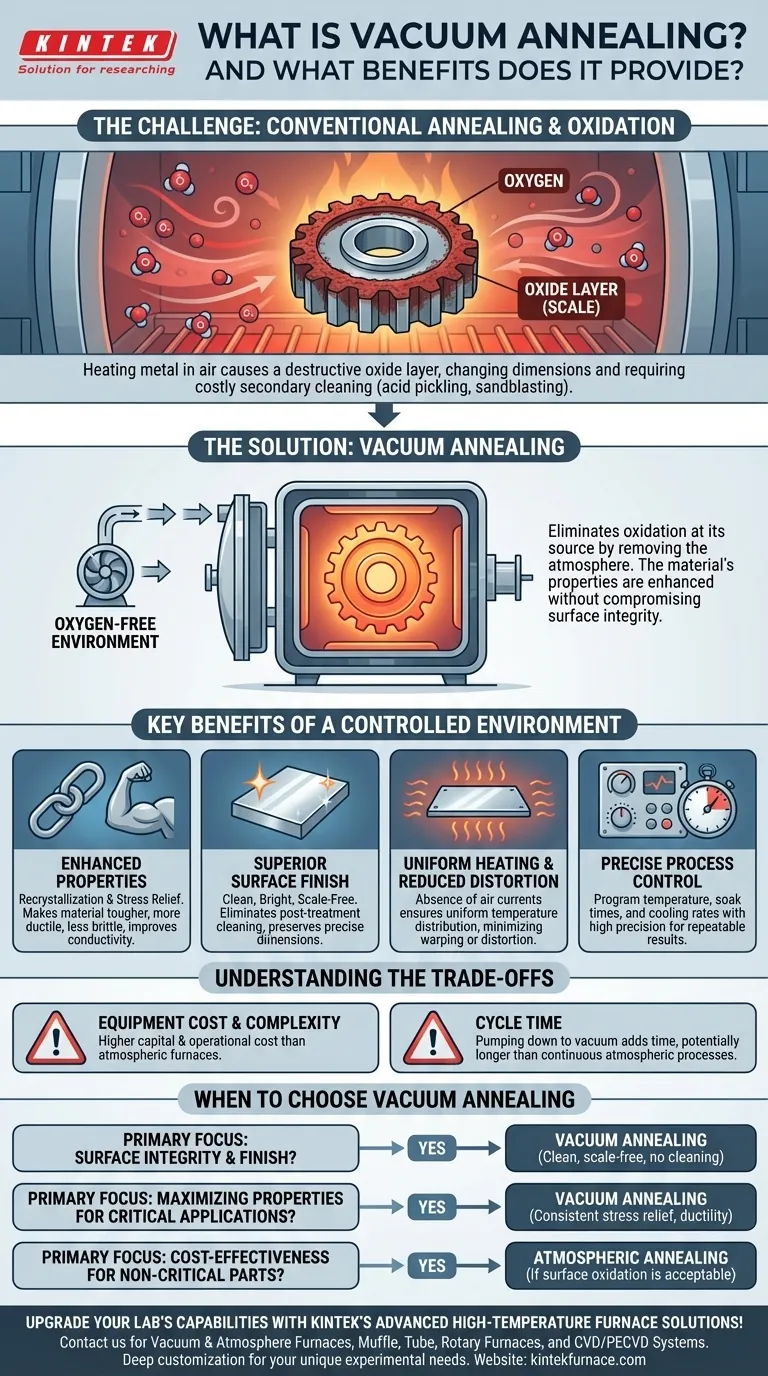

The core problem with traditional annealing is that heating metal in the presence of air causes a destructive oxide layer, or "scale," to form on its surface. Vacuum annealing fundamentally solves this by removing the atmosphere, allowing the material's properties to be enhanced without compromising its surface integrity.

How Vacuum Annealing Solves the Oxidation Problem

Annealing is essential for softening metals and making them less brittle, often after they have been hardened through work processes like stamping or drawing. The environment in which this happens is the critical difference.

The Challenge of Conventional Annealing

When a metal part is heated in a conventional furnace, it is exposed to the oxygen in the surrounding air. This oxygen reacts with the hot metal surface, forming an oxide layer.

This oxidation is often undesirable, as it changes the part's surface dimensions, can interfere with subsequent processes like plating or welding, and typically requires costly and time-consuming secondary cleaning operations like acid pickling or sandblasting.

The Vacuum Solution

Vacuum annealing eliminates this issue at its source. By placing the part in a sealed furnace chamber and pumping out the air to create a vacuum, there is virtually no oxygen left to react with the material.

The material can then be heated and cooled to achieve the desired metallurgical changes—like stress relief and recrystallization—while its surface remains clean, bright, and unchanged.

The Key Benefits of a Controlled Environment

Removing the atmosphere unlocks several key advantages that make vacuum annealing the preferred method for high-performance and precision applications.

Enhanced Material Properties

The primary goal of annealing is to improve a material's physical properties. Vacuum annealing achieves this with exceptional consistency by allowing for recrystallization and the reduction of internal stresses. This makes the material tougher, more ductile (less brittle), and can even improve electrical conductivity.

Superior Surface Finish

Because it prevents oxidation, vacuum annealing produces parts with a clean, bright, and scale-free surface. This eliminates the need for post-treatment cleaning, saving time and money while preserving the precise dimensions of the component.

Uniform Heating and Reduced Distortion

Vacuum furnaces provide extremely uniform heating. The absence of air currents ensures that the entire part, regardless of its geometry, reaches the target temperature at the same rate. This uniform heating and controlled cooling minimizes the risk of warping or distortion, which is critical for precision components.

Precise Process Control

Modern vacuum furnaces offer unparalleled control over the entire heat treatment cycle. Temperature, soak times, and cooling rates can be programmed and executed with high precision, ensuring that the process is repeatable and that the final material properties meet exact specifications.

Understanding the Trade-offs

While powerful, vacuum annealing is not the solution for every scenario. Understanding its limitations is key to making an informed decision.

Equipment Cost and Complexity

Vacuum furnaces and their associated pumping systems are significantly more expensive and complex to operate and maintain than conventional atmospheric furnaces. This higher capital and operational cost is a primary consideration.

Cycle Time

The process of pumping the furnace chamber down to the required vacuum level adds time to the overall treatment cycle. For high-volume, low-margin parts, this longer cycle time can be a disadvantage compared to faster, continuous atmospheric processes.

When It Might Be Overkill

For materials or applications where surface finish is not a critical concern and a small amount of scaling is acceptable, a simpler and more cost-effective atmospheric anneal may be perfectly adequate.

When to Choose Vacuum Annealing

Your choice of heat treatment should be driven by the specific requirements of your component and material.

- If your primary focus is surface integrity and finish: Vacuum annealing is the superior choice to produce a clean, bright, scale-free part that requires no secondary cleaning.

- If your primary focus is maximizing material properties for critical applications: The precise control and uniform heating of a vacuum furnace ensure the most consistent stress relief and ductility, especially for high-performance alloys, bearings, or medical devices.

- If your primary focus is cost-effectiveness for non-critical parts: A conventional atmospheric anneal may be sufficient if some surface oxidation is acceptable and does not interfere with the part's function.

By understanding these principles, you can confidently specify the right heat treatment to achieve your material performance and quality goals.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Oxidation | Eliminates surface scaling by removing oxygen, avoiding contamination and secondary cleaning. |

| Enhances Material Properties | Improves ductility, toughness, and reduces internal stresses through controlled recrystallization. |

| Superior Surface Finish | Produces clean, bright surfaces without oxidation, preserving dimensional accuracy. |

| Uniform Heating | Minimizes warping and distortion with even temperature distribution in a vacuum environment. |

| Precise Process Control | Allows exact programming of temperature and cooling rates for repeatable, high-quality results. |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your vacuum annealing processes and more!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control