The primary function of a Vacuum Annealing Furnace in this context is to execute a precise ageing treatment on tungsten alloys immediately following forging deformation. By maintaining the alloy at a controlled temperature range of 400°C to 500°C for an extended period, the furnace drives microstructural changes that significantly increase the material's yield strength and hardness.

Core Takeaway The Vacuum Annealing Furnace is the decisive tool for converting the potential of forged tungsten into high-performance reality. It facilitates a specific ageing process that locks in high yield strength and hardness required for critical components like flywheel rotors, while ensuring the material retains sufficient toughness to prevent failure.

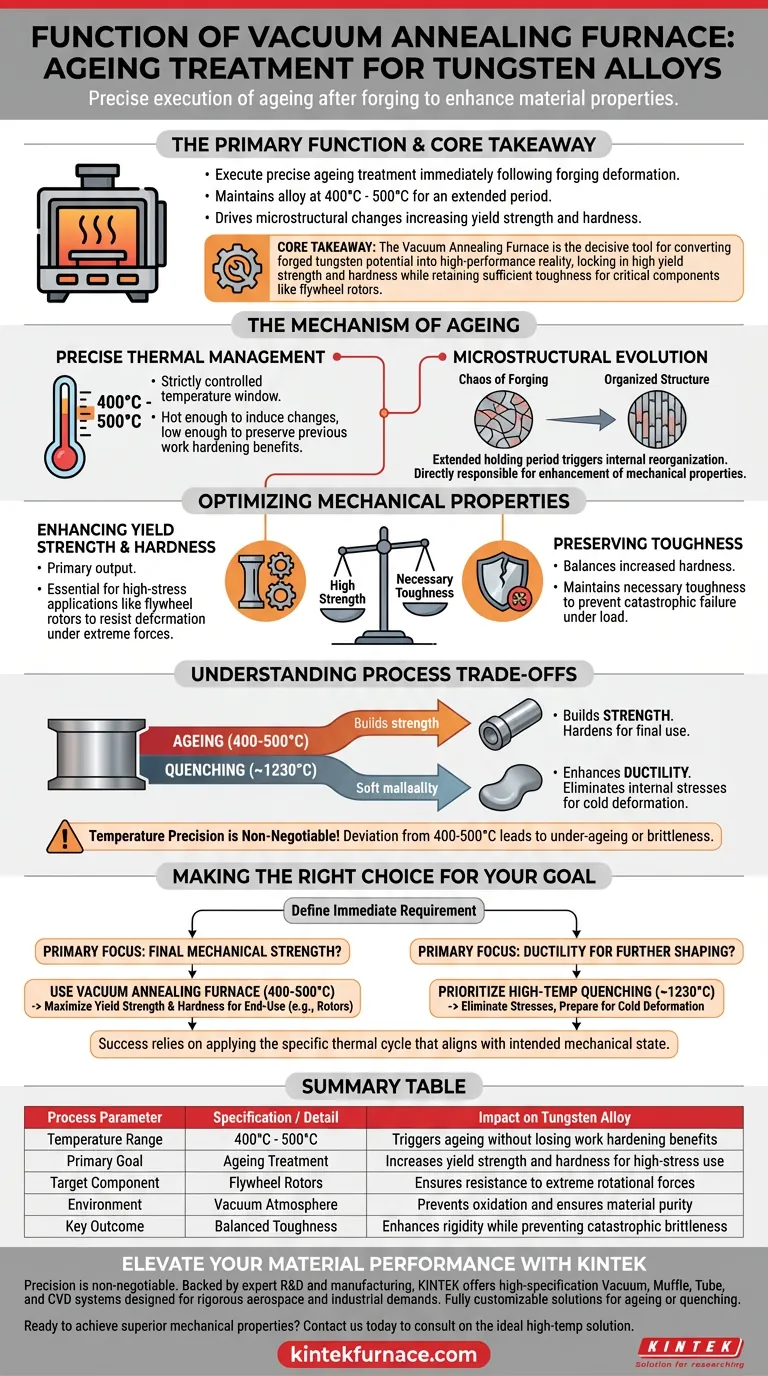

The Mechanism of Ageing

The effectiveness of tungsten alloys relies heavily on how they are treated after the initial shaping. The Vacuum Annealing Furnace is not merely for heating; it is an environment for controlled microstructural evolution.

Precise Thermal Management

The furnace maintains a strictly controlled temperature window between 400°C and 500°C.

This temperature range is critical. It is hot enough to induce necessary changes within the alloy's internal structure but low enough to avoid annealing out the benefits gained from previous work hardening.

Microstructural Evolution

During the extended holding period in the furnace, the tungsten alloy undergoes microstructural evolution.

This process settles the internal structure of the material following the chaos of forging deformation. It is this internal reorganization that is directly responsible for the enhancement of mechanical properties.

Optimizing Mechanical Properties

The ultimate goal of using a Vacuum Annealing Furnace is to meet rigorous engineering specifications.

Enhancing Yield Strength and Hardness

The primary output of this ageing treatment is a measurable improvement in yield strength and hardness.

For high-stress applications, such as flywheel rotors, the material must resist deformation under extreme rotational forces. The ageing process provides the necessary rigidity and durability to meet these high-strength specifications.

Preserving Toughness

While increasing hardness often makes materials brittle, this specific ageing process is designed to balance the trade-off.

The treatment allows the alloy to achieve high strength while simultaneously maintaining necessary toughness. This duality is essential to prevent catastrophic failure under load.

Understanding the Process Trade-offs

It is vital to distinguish between different thermal treatments for tungsten alloys, as selecting the wrong process leads to vastly different material behaviors.

Ageing vs. Quenching

While the Vacuum Annealing Furnace at 400-500°C builds strength, other processes focus on ductility.

For example, high-temperature quenching (performed at roughly 1230°C) is used to eliminate internal stresses and enhance elongation. This is distinct from the ageing process; quenching makes the material softer and more ductile for cold deformation, whereas ageing hardens it for final use.

The Role of Temperature Precision

The specific range of 400°C to 500°C is non-negotiable for this specific ageing outcome.

Deviating significantly from this range would fail to trigger the desired precipitation or structural settling, resulting in a component that either lacks the required hardness (under-ageing) or becomes too brittle (improper thermal management).

Making the Right Choice for Your Goal

To select the correct furnace capability and thermal cycle, you must define the immediate requirement for your tungsten alloy component.

- If your primary focus is Final Mechanical Strength: Utilize the Vacuum Annealing Furnace at 400-500°C to execute the ageing treatment, maximizing yield strength and hardness for end-use parts like rotors.

- If your primary focus is Ductility for Further Shaping: Prioritize a High-Temperature Quenching process (around 1230°C) to eliminate internal stresses and prepare the matrix for cold deformation.

Success in tungsten alloy processing relies on applying the specific thermal cycle that aligns with the material's intended mechanical state.

Summary Table:

| Process Parameter | Specification / Detail | Impact on Tungsten Alloy |

|---|---|---|

| Temperature Range | 400°C - 500°C | Triggers ageing without losing work hardening benefits |

| Primary Goal | Ageing Treatment | Increases yield strength and hardness for high-stress use |

| Target Component | Flywheel Rotors | Ensures resistance to extreme rotational forces |

| Environment | Vacuum Atmosphere | Prevents oxidation and ensures material purity |

| Key Outcome | Balanced Toughness | Enhances rigidity while preventing catastrophic brittleness |

Elevate Your Material Performance with KINTEK

Precision is non-negotiable when treating high-performance tungsten alloys. Backed by expert R&D and manufacturing, KINTEK offers high-specification Vacuum, Muffle, Tube, and CVD systems designed to meet the rigorous thermal demands of aerospace and industrial engineering. Whether you need to maximize yield strength through ageing or enhance ductility via quenching, our furnaces are fully customizable for your unique laboratory or production needs.

Ready to achieve superior mechanical properties? Contact us today to consult with our experts on the ideal high-temp solution for your application.

Visual Guide

References

- Adéla Macháčková, Silvie Brožová. Applications of Tungsten Pseudo-Alloys in the Energy Sector. DOI: 10.3390/app14020647

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What role does a vacuum drying oven play in Ru-Mo2C@CN post-treatment? Preserve Morphology & Catalytic Activity

- How do the radiant heating and controlled cooling functions of a vacuum brazing furnace benefit Kovar-to-SS joints?

- How does a retort furnace differ from a vacuum furnace? Choose the Right Heat Treatment for Your Materials

- Why is a vacuum oven required for post-processing WTaVTiZrx alloy powders? Ensure Purity and Prevent Oxidation

- Why is a water cooling system necessary in a vacuum furnace? Ensure Safety and Performance in High-Temp Processes

- How does Diamond Burnishing (DB) and Low-Temperature Gaseous Nitriding (LTGN) improve material output?

- How does increasing the vacuum furnace annealing temperature to 900 K adversely affect Ti–TEG composites?

- Why is a precision vacuum drying oven required for processing electrode sheets in LMFP slurry coating? Essential Drying