In essence, a retort furnace creates a controlled gas atmosphere, while a vacuum furnace removes the atmosphere entirely. This core difference determines their function: retort furnaces use specific gases to protect or interact with a material, whereas vacuum furnaces create an ultra-pure environment by eliminating all gases to prevent any atmospheric interaction.

The choice between a retort and a vacuum furnace is not about which is superior, but about the role you want the atmosphere to play. A retort furnace controls the composition of the atmosphere, while a vacuum furnace seeks to eliminate it.

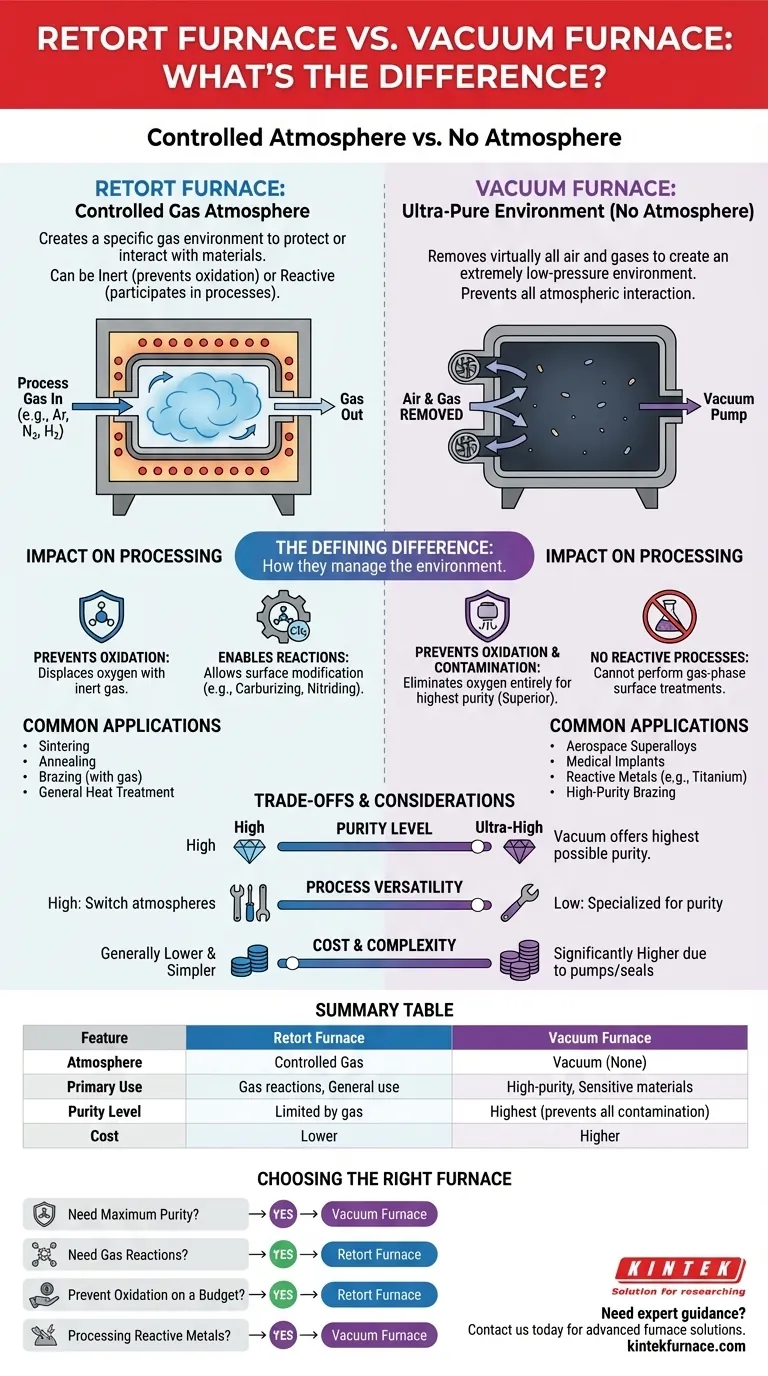

The Defining Difference: Atmosphere vs. Vacuum

The fundamental distinction between these two technologies lies in how they manage the environment inside the heating chamber. This single factor dictates their capabilities and ideal applications.

How a Retort Furnace Works

A retort furnace uses a sealed, gas-tight container—the retort—placed inside the furnace. This vessel is purged of ambient air and filled with a specific process gas.

The goal is to create a precisely controlled atmosphere. This atmosphere can be inert (like argon or nitrogen) to prevent oxidation, or it can be reactive (like hydrogen) to actively participate in a chemical process like surface reduction.

How a Vacuum Furnace Works

A vacuum furnace is a tightly sealed vessel equipped with powerful pumps designed to remove virtually all air and other gases from the chamber before heating begins.

Its purpose is to create an environment with extremely low pressure, or a vacuum. This prevents oxidation and contamination far more effectively than simply displacing air with an inert gas, making it essential for highly sensitive materials.

A Note on Terminology: Retort vs. Muffle

The terms "retort furnace" and "muffle furnace" are often used interchangeably. Historically, the retort is the sealed pot holding the material, while the muffle is the separated chamber that prevents direct contact between the heating elements and the workpiece. In modern practice, both describe a furnace designed for controlled atmosphere processing.

Impact on Material Processing

The choice of environment—controlled gas or vacuum—has direct consequences for the final properties of the material being processed.

Preventing Oxidation and Contamination

Both furnaces excel at preventing oxidation, but they do so differently. A retort furnace uses an inert gas to displace oxygen. A vacuum furnace removes the oxygen altogether.

For the highest level of purity and for processing extremely reactive metals like titanium, the near-total absence of gas in a vacuum furnace is superior.

Enabling Specific Chemical Reactions

This is where a retort furnace has a unique advantage. By introducing reactive gases, you can intentionally alter a material's surface chemistry.

Processes like carburizing (adding carbon), nitriding (adding nitrogen), or using hydrogen for oxide reduction are only possible in a retort furnace where a specific process gas is required.

Common Applications

A retort furnace is a workhorse for processes like sintering, annealing, and brazing where a specific, clean atmosphere is needed but an ultra-high vacuum is not.

A vacuum furnace is reserved for the most demanding applications, such as heat-treating aerospace superalloys, brazing complex medical implants, and processing materials that cannot tolerate any atmospheric contamination.

Understanding the Trade-offs

Choosing between these technologies involves balancing purity requirements, process capabilities, and cost.

Purity and Process Control

A vacuum furnace offers the highest possible purity. The level of cleanliness is limited only by the quality of the vacuum that can be achieved.

A retort furnace's purity is limited by the purity of the process gas being used. While excellent for most applications, it cannot match the inertness of a deep vacuum.

Process Versatility

Retort furnaces are more versatile for processes that depend on a gas-phase reaction. You can switch between inert, oxidizing, or reducing atmospheres in the same piece of equipment.

Vacuum furnaces are specialized. They excel at creating a pure environment but cannot perform processes that require an active gas atmosphere.

Cost and Complexity

Vacuum furnaces are significantly more complex and expensive. The high-vacuum pumps, robust chamber construction, and sophisticated sealing systems represent a major investment.

Retort furnaces are generally simpler in design and more cost-effective, making them a practical choice for a wider range of general-purpose heat treatment applications.

Choosing the Right Furnace for Your Process

Your material and your process goal are the only factors that matter. Use this guide to make a clear decision.

- If your primary focus is maximum purity and preventing any oxidation: A vacuum furnace is the definitive choice for sensitive and reactive materials.

- If your process requires a specific gas to react with the material (e.g., reduction, nitriding): A retort furnace is your only option, as it is designed to contain process gases.

- If you need to prevent oxidation for common materials on a practical budget: A retort furnace with an inert gas like argon or nitrogen is a highly effective and standard solution.

- If you are heat treating highly reactive metals like titanium or aerospace superalloys: The high-purity environment of a vacuum furnace is non-negotiable.

Understanding the fundamental role of the atmosphere is the key to selecting the right thermal processing technology for your materials.

Summary Table:

| Feature | Retort Furnace | Vacuum Furnace |

|---|---|---|

| Atmosphere | Controlled gas (e.g., inert or reactive) | Vacuum (no atmosphere) |

| Primary Use | Sintering, annealing, brazing with gas reactions | High-purity heat treatment for sensitive materials |

| Purity Level | Limited by gas purity | Highest purity, prevents all contamination |

| Cost | Generally lower and simpler | Higher due to complexity and vacuum systems |

Need expert guidance on selecting the perfect furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements. Contact us today to enhance your material processing efficiency and achieve superior results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity