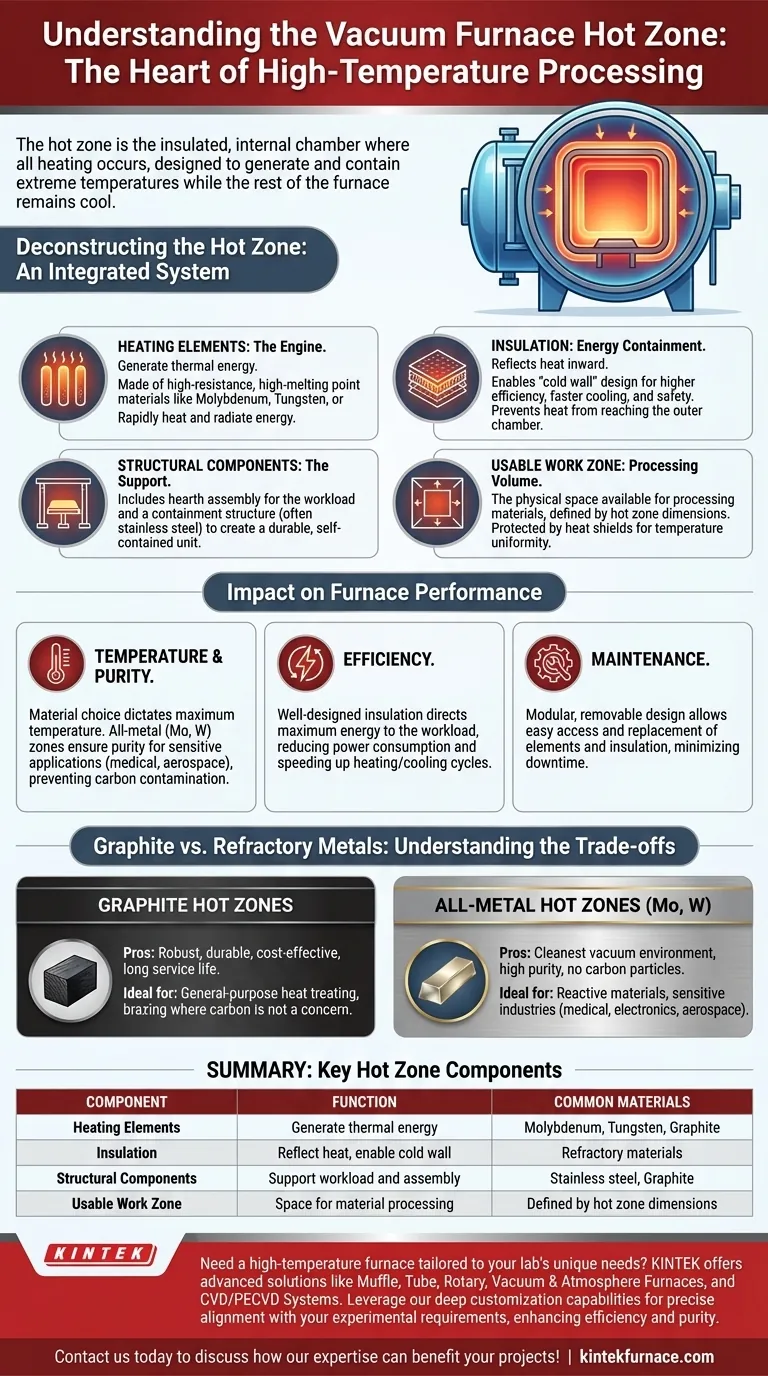

In any vacuum furnace, the hot zone is the insulated, internal chamber where all heating occurs. It is an engineered assembly of components designed to generate and contain extreme temperatures while the rest of the furnace remains cool. The materials used for its construction are typically either graphite or refractory metals like molybdenum and tungsten, chosen based on the specific process requirements.

The hot zone is not merely the "hot part" of the furnace; it is a precisely engineered system of heating elements, insulation, and structural supports. Its design and material composition directly dictate the furnace's maximum temperature, efficiency, and suitability for specific applications.

Deconstructing the Hot Zone: More Than Just Heat

To truly understand a vacuum furnace, you must see the hot zone as an integrated system rather than a single part. It is typically designed to be removable for maintenance and consists of several critical components working in unison.

Heating Elements: The Engine of the Furnace

The heating elements are the components that generate the thermal energy. They are typically made from materials with high electrical resistance and an extremely high melting point, such as molybdenum, tungsten, or graphite. An electrical current is passed through them, causing them to heat up rapidly and radiate that energy into the usable work zone.

Insulation: Containing the Energy

Surrounding the heating elements is a package of insulation. This is crucial for reflecting heat inward toward the workload and preventing it from reaching the outer vacuum chamber. This thermal containment is what enables "cold wall" furnace designs, leading to higher efficiency, faster cooling cycles, and a safer operating environment.

Structural Components: The Support System

The hot zone includes a hearth assembly, which is the robust platform where the workload (the material being treated) rests. The entire assembly of elements and insulation is held within a containment structure, often made of stainless steel, to create a durable, self-contained unit.

The Usable Work Zone

The dimensions of the hot zone define the usable work zone—the physical volume available for processing materials. This space is protected by components like heat shields and pneumatically operated doors that seal the zone during the heating cycle, ensuring temperature uniformity.

How the Hot Zone Influences Furnace Performance

The selection of hot zone materials and its construction quality are not minor details; they are fundamental to the furnace's capabilities.

Impact on Temperature and Purity

The material of the heating elements directly determines the maximum achievable temperature. More importantly, the hot zone material can interact with the process atmosphere. For applications requiring extreme purity, such as in the medical or aerospace industries, an all-metal hot zone is often required to prevent any potential carbon contamination from graphite components.

Impact on Efficiency

A well-designed insulation package is the key to thermal efficiency. It ensures that the maximum amount of energy is directed at the workload, reducing power consumption and allowing for faster heating and cooling cycles.

Impact on Maintenance

The modular, removable design of most modern hot zones is a critical feature for maintenance. Heating elements and insulation have a finite lifespan, and the ability to easily access and replace them minimizes downtime and reduces long-term operational costs.

Understanding the Trade-offs: Graphite vs. Refractory Metals

The most significant decision in hot zone design is the choice between an all-graphite construction and an all-metal one. This choice presents a clear trade-off between cost, performance, and application.

The Case for Graphite Hot Zones

Graphite is a robust, durable, and relatively low-cost material. It is an excellent choice for general-purpose heat treating and brazing applications where the presence of carbon is not a concern. It offers a long service life and is simple to maintain.

The Case for All-Metal Hot Zones

Hot zones constructed entirely from refractory metals like molybdenum and tungsten are chosen for high-purity applications. They provide the cleanest possible vacuum environment, free from the carbon particles associated with graphite. This is essential when treating reactive materials or manufacturing components for sensitive industries like medical, electronics, and aerospace.

Matching the Hot Zone to Your Application

The hot zone is the heart of the furnace, and its specifications must align with your processing goals. When evaluating a furnace, consider the following.

- If your primary focus is general heat treating at high temperatures: A graphite hot zone offers the most cost-effective and durable solution.

- If your primary focus is process purity for sensitive materials: An all-metal hot zone made of molybdenum or tungsten is necessary to avoid carbon contamination.

- If your primary focus is maximum operational efficiency: The design of the insulation package and its integration with the heating elements is the most critical factor to evaluate.

Understanding the hot zone's construction is the key to selecting a vacuum furnace that truly meets your technical and operational requirements.

Summary Table:

| Component | Function | Common Materials |

|---|---|---|

| Heating Elements | Generate thermal energy | Molybdenum, Tungsten, Graphite |

| Insulation | Reflect heat inward, enable cold wall design | Refractory materials |

| Structural Components | Support workload and assembly | Stainless steel, Graphite |

| Usable Work Zone | Space for material processing | Defined by hot zone dimensions |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise alignment with your experimental requirements for enhanced efficiency and purity. Contact us today to discuss how our expertise can benefit your projects!

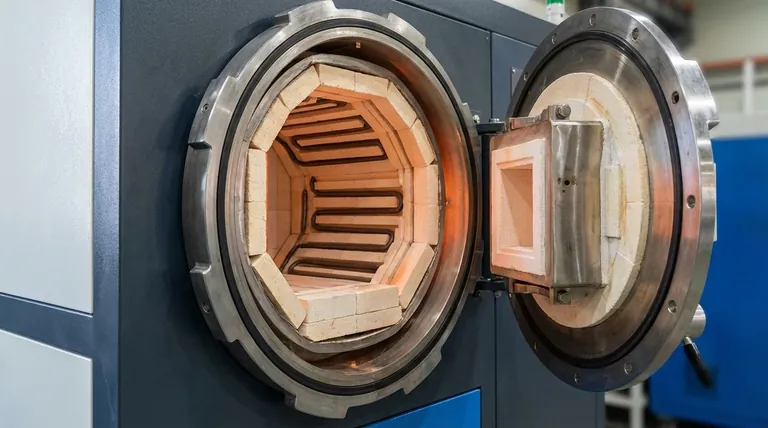

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control