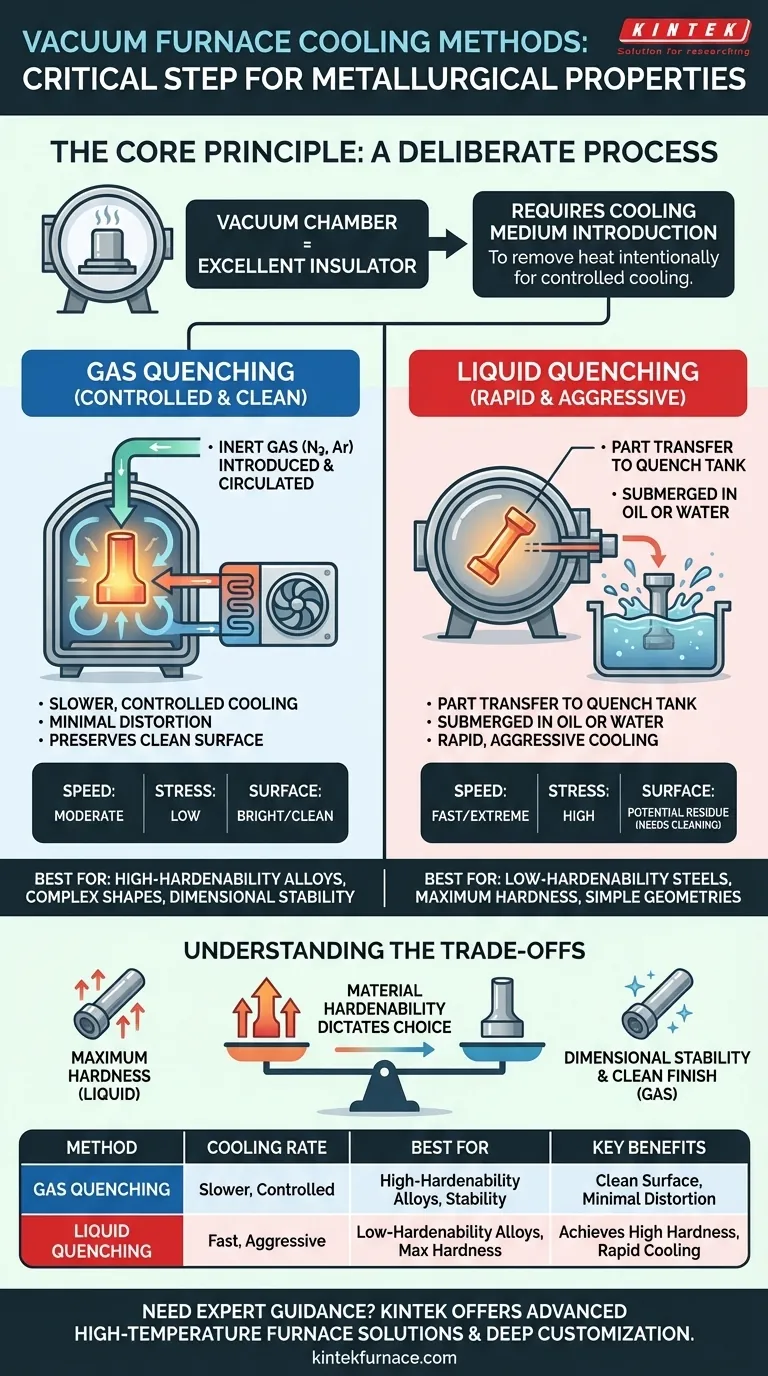

In short, parts are cooled after vacuum furnace heat treatment using two primary methods: controlled gas quenching and rapid liquid quenching. Gas quenching involves introducing an inert gas like argon or nitrogen into the chamber for a slower, more controlled cool-down, preserving the part's clean surface. Liquid quenching involves submerging the part in oil or water for a much faster cool-down, typically to achieve maximum hardness in certain metals.

The method used for cooling is not an afterthought; it is a critical step that defines the final metallurgical properties of the component. The choice between gas and liquid quenching is a deliberate trade-off between achieving maximum hardness and maintaining dimensional stability.

The Core Principle of Vacuum Cooling

Why Cooling is a Deliberate Process

A vacuum is an excellent insulator. Because there is no air or other medium in the chamber to transfer heat away, a part will not cool down on its own at any meaningful rate.

To cool the component, we must intentionally introduce a cooling medium into the controlled environment. The choice of this medium and the speed at which it removes heat are fundamental to the success of the heat treatment process.

Primary Cooling Methods Explained

Gas Quenching

Gas quenching, or gas cooling, involves backfilling the sealed vacuum chamber with a high-purity inert gas. Nitrogen is common and cost-effective, while argon is used for materials that might react with nitrogen at high temperatures.

This gas is circulated by a high-power fan, transferring heat from the component to a heat exchanger. By controlling the gas pressure and velocity, operators can precisely manage the cooling rate. This method is ideal for minimizing distortion and maintaining the clean, oxide-free surface finish achieved in the vacuum.

Liquid Quenching

Liquid quenching is a much more aggressive cooling method used to achieve specific metallurgical transformations, particularly for hardening steels. Immediately after the heating cycle, the part is mechanically transferred from the vacuum chamber into an integrated, sealed tank containing a quenching liquid.

The two most common liquids used are:

- Oil Quenching: Provides a very fast cooling rate that is less severe than water. It is widely used for hardening a variety of alloy steels, as it reduces the risk of quench cracking.

- Water Quenching: Offers an extremely rapid cooling rate, but the thermal shock is immense. It is typically reserved for low-carbon steels or alloys that require a drastic quench to achieve full hardness.

Some furnaces may also support other media like nitrate salts for specialized processes.

Understanding the Trade-offs

Speed vs. Internal Stress

The primary trade-off is between the cooling rate and the risk of negative consequences.

- Fast Cooling (Liquid Quench): Achieves maximum hardness but induces significant internal stress. This increases the risk of part distortion, warping, or even cracking, especially in complex geometries.

- Slow Cooling (Gas Quench): Provides excellent dimensional stability and minimizes internal stress. However, the cooling rate may not be fast enough to achieve the required hardness for certain low-hardenability alloys.

Surface Finish vs. Post-Processing

A key benefit of vacuum heat treatment is producing bright, clean parts.

- Gas Quenching: Perfectly preserves this clean surface, as the part is never exposed to a contaminating environment.

- Liquid Quenching: Can leave an oily residue or surface film that requires a secondary cleaning operation, adding time and cost to the production cycle.

Material Hardenability

The choice is fundamentally dictated by the material's properties. "Hardenability" refers to a material's ability to be hardened by heat treatment.

- High-Hardenability Alloys (e.g., many tool steels): These materials transform to a hardened state even with slower cooling rates. A controlled gas quench is often sufficient and highly desirable.

- Low-Hardenability Alloys (e.g., some carbon steels): These materials require an extremely fast cooling rate to prevent the formation of soft microstructures. A rapid oil or water quench is often necessary.

Making the Right Choice for Your Goal

Selecting the correct cooling method requires aligning the process with your material and desired final properties.

- If your primary focus is achieving maximum hardness in a low-hardenability steel: A rapid liquid quench (oil or water) is necessary.

- If your primary focus is dimensional stability and a clean finish on a high-hardenability alloy: Controlled inert gas quenching is the superior choice.

- If your primary focus is stress relief or annealing: A very slow, programmed cooling cycle using low-pressure gas or simply letting the furnace cool naturally is required.

- If you are treating parts with complex shapes or thin cross-sections: Prioritize a slower gas quench to prevent distortion and cracking, provided the material's hardenability allows it.

Ultimately, the cooling method is an engineered decision that directly determines the component's performance and reliability.

Summary Table:

| Method | Cooling Rate | Best For | Key Benefits |

|---|---|---|---|

| Gas Quenching | Slower, controlled | High-hardenability alloys, dimensional stability | Clean surface, minimal distortion |

| Liquid Quenching | Fast, aggressive | Low-hardenability alloys, maximum hardness | Achieves high hardness, rapid cooling |

Need expert guidance on vacuum furnace cooling for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your heat treatment processes and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics