In short, vacuum furnaces are compatible with a vast range of materials, including most metals and many ceramics, for nearly any heat treatment process. Their primary function is to perform processes like annealing, brazing, sintering, and hardening in a controlled environment that prevents oxidation and ensures material purity and uniformity.

The core principle of vacuum furnace compatibility is not just about the material itself, but about using the vacuum to eliminate unwanted reactions with atmospheric gases. This makes it the ideal choice for processes where surface finish, material purity, and precise metallurgical properties are critical.

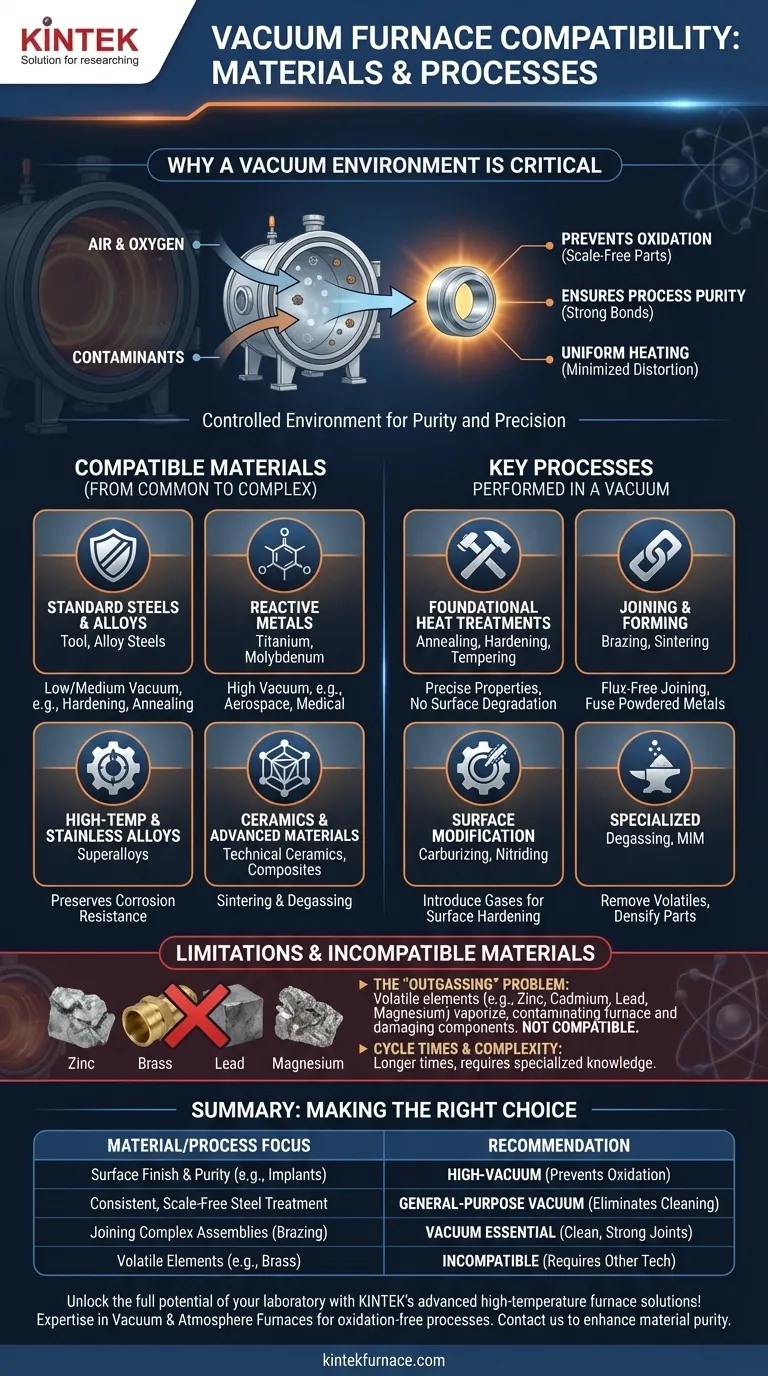

Why a Vacuum Environment Is Critical

The decision to use a vacuum furnace is driven by the need for absolute control over the processing environment. Removing air and other gases from the chamber fundamentally changes how materials react to heat.

Preventing Oxidation and Contamination

The most immediate benefit of a vacuum is the removal of oxygen. At high temperatures, oxygen aggressively reacts with most metals, forming a layer of oxide scale on the surface.

A vacuum environment prevents this, resulting in clean, bright parts that often require no post-process cleaning. This is essential for high-value components where surface integrity is paramount.

Ensuring Process Purity

Processes like brazing and sintering rely on creating perfect metallurgical bonds between materials. Any contaminants, especially oxides, can interfere with this bonding and create weak points.

A vacuum ensures that the surfaces remain perfectly clean, allowing braze alloys to flow freely and metal powders to sinter into a strong, dense final part.

Achieving Uniform Heating and Cooling

In a vacuum, heat transfer occurs primarily through radiation, which is highly uniform and predictable. This minimizes thermal gradients within the material, reducing the risk of distortion and warping.

This level of control is crucial for processing complex geometries or materials with tight dimensional tolerances.

Compatible Materials: From Common to Complex

While incredibly versatile, the choice of vacuum level and furnace configuration depends heavily on the material being processed.

Standard Steels and Alloys

Even common materials like tool steels and alloy steels benefit from vacuum processing. Processes like hardening, tempering, and annealing can be performed without creating surface scale, improving the final part's quality and consistency. These typically use low to medium vacuum levels.

Reactive Metals (Titanium, Molybdenum)

Metals like titanium, molybdenum, and their alloys have a very high affinity for oxygen, nitrogen, and hydrogen, especially at elevated temperatures.

Processing these materials requires a high-vacuum environment to prevent them from becoming brittle or contaminated. This makes vacuum furnaces essential in the aerospace and medical implant industries.

High-Temperature and Stainless Alloys

Nickel-based superalloys and stainless steels are often vacuum heat-treated to achieve specific mechanical properties for demanding applications. The vacuum preserves their corrosion resistance and surface finish.

Ceramics and Advanced Materials

Vacuum furnaces are also used for sintering technical ceramics and degassing composite materials. The controlled atmosphere is vital for achieving the desired density and removing trapped volatile compounds.

Key Processes Performed in a Vacuum

The list of compatible processes is extensive, covering nearly every aspect of modern heat treatment.

Foundational Heat Treatments

Processes like annealing (softening), hardening (strengthening), and tempering (toughness control) are staples of vacuum furnace work. The vacuum ensures the final metallurgical properties are achieved precisely and without surface degradation.

Joining and Forming

Vacuum brazing is a premier process for joining complex components without the need for corrosive fluxes. Vacuum sintering is used to fuse powdered metals into solid parts, a key step in metal injection molding (MIM) and additive manufacturing.

Surface Modification

While a vacuum removes atmosphere, it also allows for the precise introduction of specific gases. In processes like vacuum carburizing or nitriding, a low-pressure hydrocarbon or nitrogen-rich gas is introduced to intentionally diffuse carbon or nitrogen into a part's surface, hardening it.

Understanding the Trade-offs and Limitations

While powerful, vacuum furnaces are not a universal solution. Understanding their limitations is key to using them effectively.

The "Outgassing" Problem

The most significant limitation is material outgassing. Certain elements with a high vapor pressure—such as zinc, cadmium, lead, and magnesium—will vaporize in a vacuum at high temperatures.

Processing materials containing these elements (like brass) can contaminate the furnace interior, damage heating elements, and ruin subsequent loads. These materials are generally incompatible with vacuum processing.

Process Cycle Time

Achieving a deep vacuum and cooling the workload under controlled conditions can be time-consuming. Cycle times for vacuum furnaces are often longer than for conventional atmospheric furnaces.

Cost and Complexity

Vacuum furnaces represent a significant capital investment. Their operation and maintenance require specialized knowledge of vacuum systems, pumps, and controls, adding to their operational complexity and cost.

Making the Right Choice for Your Application

Selecting the right process depends entirely on your material and your final goal.

- If your primary focus is surface finish and material purity (e.g., medical implants, aerospace parts): A high-vacuum furnace is non-negotiable to prevent any oxidation or contamination.

- If your primary focus is consistent, scale-free heat treatment of standard steels: A general-purpose vacuum furnace provides superior results over atmospheric furnaces by eliminating post-process cleaning.

- If your primary focus is joining complex assemblies (brazing): A vacuum environment is essential for creating clean, strong, and flux-free joints, especially with stainless steels or superalloys.

- If your primary focus is processing materials with volatile elements (e.g., brass, galvanized steel): A standard vacuum furnace is incompatible due to outgassing; another heating technology is required.

By understanding these core principles, you can confidently determine if a vacuum furnace is the right tool to achieve superior material properties and product quality.

Summary Table:

| Material/Process Type | Key Compatibility Details |

|---|---|

| Standard Steels and Alloys | Compatible with annealing, hardening, tempering; prevents oxidation, uses low to medium vacuum. |

| Reactive Metals (e.g., Titanium) | Requires high vacuum to avoid contamination; essential for aerospace and medical industries. |

| Ceramics and Advanced Materials | Used for sintering and degassing; ensures density and removes volatiles in controlled atmosphere. |

| Key Processes (e.g., Brazing, Sintering) | Enables flux-free joining and strong bonds; ideal for uniform heating and surface modification. |

| Incompatible Materials (e.g., Zinc, Brass) | Avoid due to outgassing risks; can contaminate furnace and damage components. |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Whether you're working with reactive metals, ceramics, or standard alloys, our expertise in vacuum and atmosphere furnaces ensures precise control for oxidation-free processes like annealing, brazing, and sintering. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Don't let contamination or inconsistent results hold you back—contact us today to discuss how we can enhance your material purity and process efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability