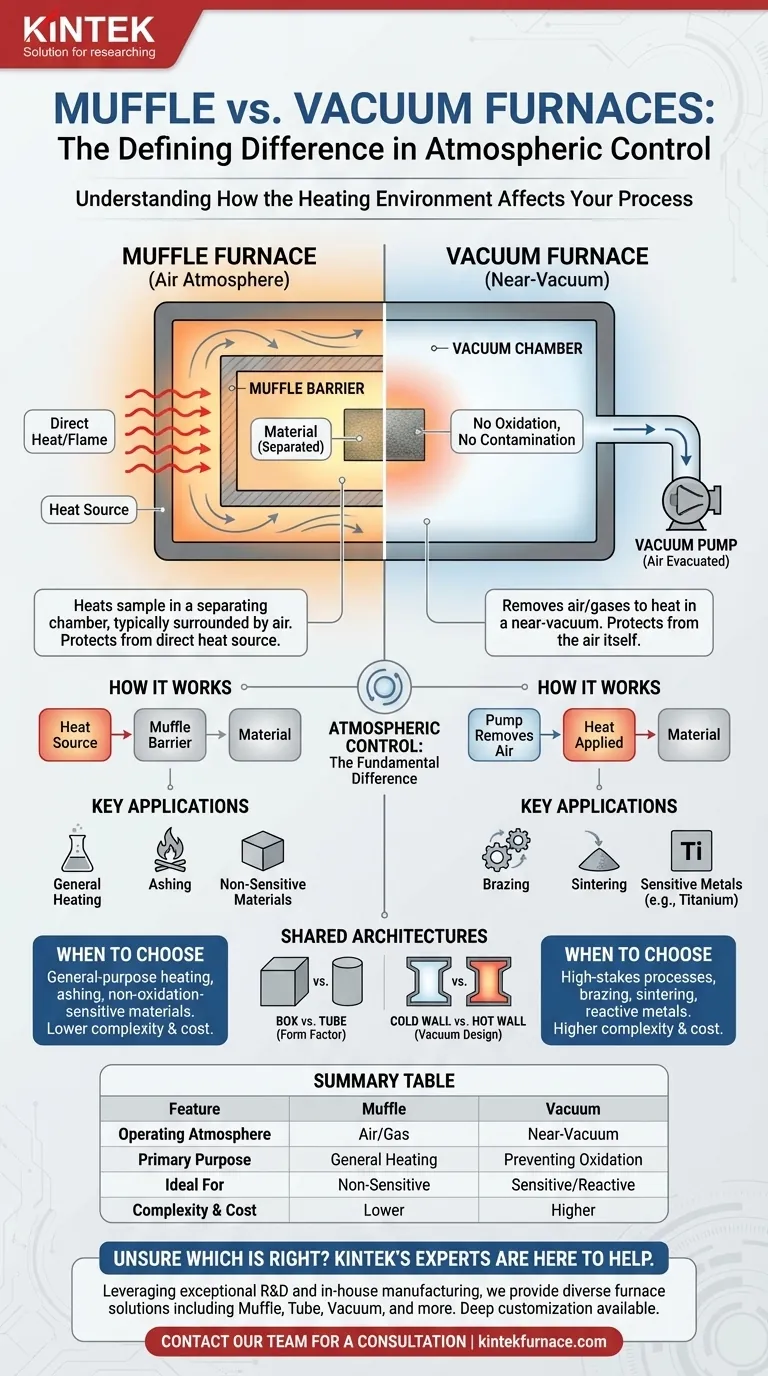

The fundamental difference between a muffle furnace and a vacuum furnace lies in the atmosphere where the material is heated. A muffle furnace heats a sample within a separating chamber (the "muffle") that is typically surrounded by air, while a vacuum furnace first removes the air and other gases to heat the sample in a near-vacuum. This single difference in atmospheric control dictates their distinct applications, capabilities, and outcomes.

The choice between a muffle and a vacuum furnace is not about which is "better," but which provides the correct environment for your process. Muffle furnaces protect a material from the direct heat source, while vacuum furnaces protect a material from the air itself.

The Defining Difference: Atmospheric Control

The core function of any furnace is to apply heat, but the environment in which that heat is applied is just as critical. The primary distinction between these two furnace types is how they manage that environment.

How a Muffle Furnace Works

A muffle furnace uses a physical barrier—the muffle—to isolate the material being heated from the direct radiation or flame of the heating elements.

This muffle is essentially a sealed chamber or box placed inside the larger furnace. Think of it like putting food in a covered ceramic dish before placing it in an oven. The dish protects the food from direct, harsh heat.

These furnaces typically operate in an ambient air atmosphere. Their main purpose is to provide uniform heating and prevent contamination from combustion byproducts if a fuel-fired heat source is used.

How a Vacuum Furnace Works

A vacuum furnace is designed to heat materials in a highly controlled, gas-free environment. The first step in its operation is to use a pump to evacuate nearly all the air from its sealed chamber.

By removing oxygen and other reactive gases, the furnace prevents oxidation, contamination, and other unwanted chemical reactions that occur when materials are heated in air.

This process is critical for processing sensitive materials that would be damaged or destroyed by exposure to oxygen at high temperatures.

Understanding Key Furnace Architectures

While "muffle" and "vacuum" describe the atmosphere, other terms describe the furnace's physical shape and thermal design. These concepts can apply to both types.

Form Factor: Box vs. Tube

Furnaces are often categorized by their shape. A box furnace has a larger, cube-shaped chamber suitable for bulkier items. A tube furnace uses a long cylindrical tube, often for processing materials that pass through it continuously.

Either a box or a tube furnace can be designed to operate with a muffle or under a vacuum, depending on the application's needs.

Vacuum Design: Cold Wall vs. Hot Wall

Vacuum furnaces have an important internal distinction. A cold wall design features a heating system inside a chamber with a water-cooled outer shell. This shell remains near room temperature, allowing for very rapid heating and cooling cycles, higher maximum temperatures, and excellent temperature uniformity.

A hot wall design places the heating system outside the vacuum retort. This simpler design is generally limited to lower temperatures and has slower heating/cooling cycles compared to its cold wall counterpart.

Understanding the Trade-offs

Choosing the wrong furnace type can lead to failed processes, damaged materials, and wasted resources. The decision hinges entirely on your material and desired outcome.

When to Choose a Muffle Furnace

A muffle furnace is the ideal choice for general-purpose heating, ashing (burning off organic material), and heat-treating materials that are not sensitive to oxidation.

They are simpler, less expensive to operate, and perfectly suitable when the primary goal is simply to heat a sample to a specific temperature in an air atmosphere.

When to Choose a Vacuum Furnace

A vacuum furnace is essential for high-stakes processes like brazing, sintering, and heat-treating reactive metals and advanced alloys (e.g., titanium or superalloys).

If your process requires an exceptionally clean environment to prevent any surface oxidation or contamination, a vacuum furnace is the only reliable option. The results are highly precise and repeatable.

The Hybrid Option: Controlled Atmosphere

Modern furnaces can blur these lines. Some muffle furnaces can be purged with an inert gas (like argon) to create a controlled, non-oxidizing atmosphere without the expense of a full vacuum system.

Furthermore, advanced vacuum muffle furnaces exist, combining technologies to offer extremely precise atmospheric control for specialized lab applications, demonstrating how these core principles can be integrated.

Making the Right Choice for Your Process

Your material's chemical properties and your process goals should be the only factors that guide your decision.

- If your primary focus is general heating, ashing, or material testing in an air atmosphere: A muffle furnace is the direct, cost-effective solution.

- If your primary focus is preventing oxidation and contamination for sensitive materials: A vacuum furnace is non-negotiable for achieving clean, high-quality results.

- If your primary focus is high-performance heat treatment with rapid cycling: A cold-wall vacuum furnace offers the superior temperature control and speed required for advanced applications.

Ultimately, understanding the atmosphere your material requires is the key to selecting the correct thermal processing tool.

Summary Table:

| Feature | Muffle Furnace | Vacuum Furnace |

|---|---|---|

| Operating Atmosphere | Air or controlled gas | Near-vacuum or inert gas |

| Primary Purpose | General heating, ashing, heat-treating non-sensitive materials | Preventing oxidation, brazing, sintering sensitive materials |

| Ideal For | Processes where oxidation is not a concern | Processes requiring a clean, contamination-free environment |

| Complexity & Cost | Generally simpler and lower cost | More complex and higher cost |

Unsure which furnace is right for your application?

KINTEK's experts are here to help. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Contact our team today for a personalized consultation to select the perfect furnace for your process, ensuring optimal results, efficiency, and material integrity.

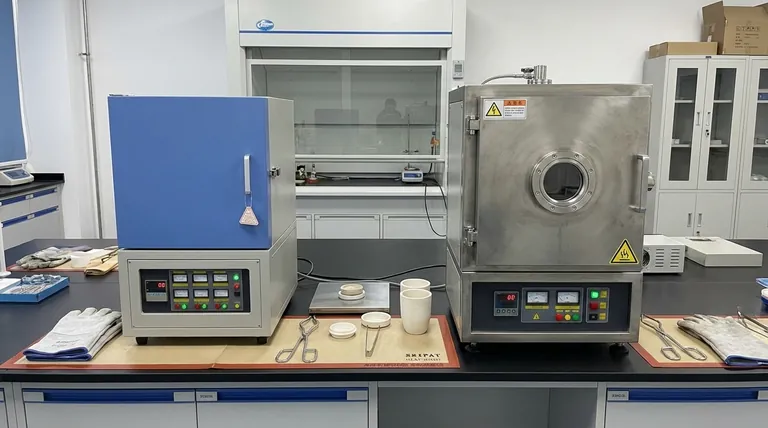

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO