The necessity is clear: evacuating a furnace to a high vacuum level of 10⁻³ Pa is a critical, non-negotiable step to thoroughly remove reactive gases like oxygen and water vapor from the chamber. At the high temperatures required for melting, AM60 magnesium alloy is extremely reactive and would otherwise be lost to rapid, uncontrolled oxidation, severely compromising the quality and yield of the final product.

The core principle is not about melting the metal in a vacuum, but about using the vacuum to perform a "deep clean" of the environment. This initial evacuation creates a chemically pure foundation upon which a stable, protective atmosphere can be built, ensuring the integrity of the highly sensitive magnesium alloy.

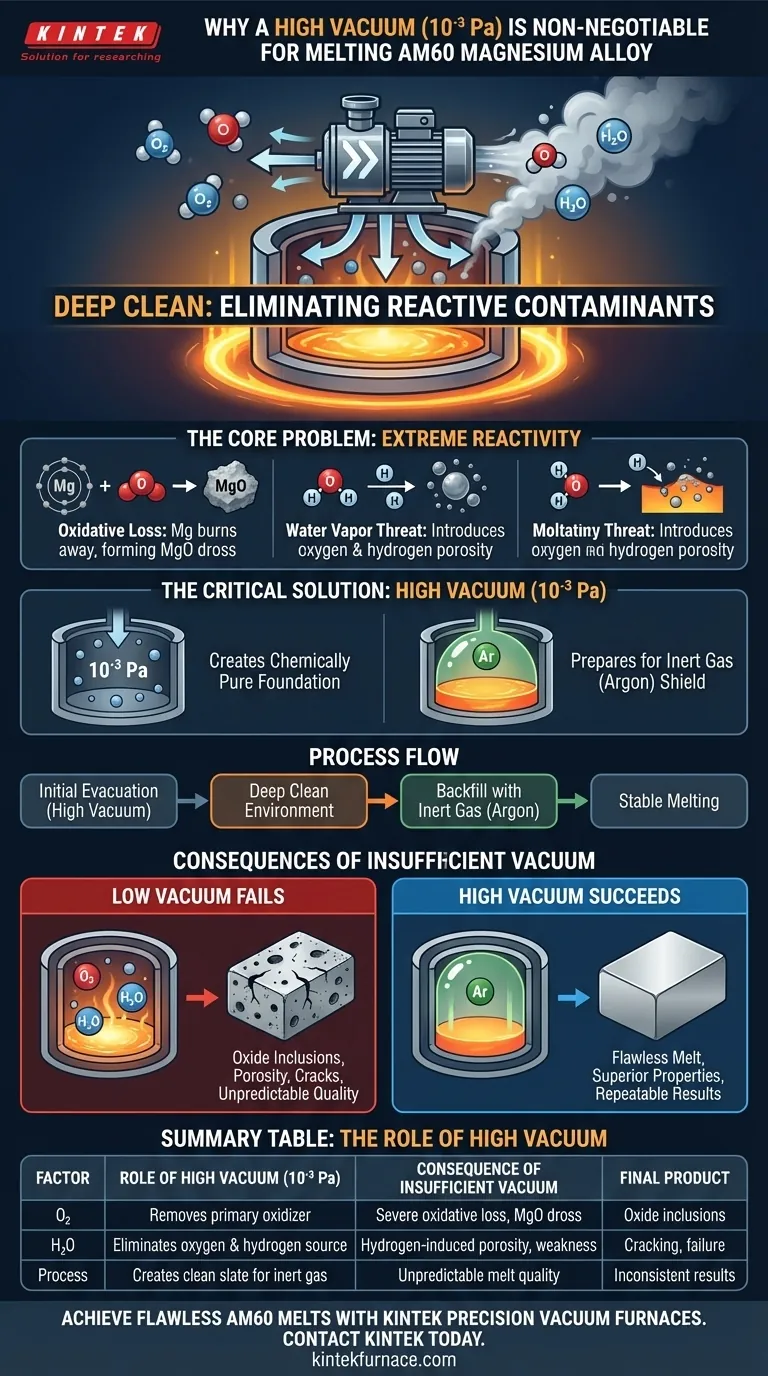

The Primary Role of a High Vacuum: Eliminating Reactive Contaminants

Melting a reactive alloy like AM60 is fundamentally a challenge of environmental control. The initial high vacuum is the most important step in establishing that control.

Magnesium's Extreme Reactivity

Magnesium is an alkaline earth metal with a very high affinity for oxygen. This reactivity increases dramatically as it approaches its melting point (around 650°C) and becomes even more aggressive in its liquid state.

The Direct Threat of Oxygen

Any residual oxygen left in the furnace will readily react with the hot magnesium to form magnesium oxide (MgO). This process, known as oxidative loss, is essentially the metal burning away. It reduces the usable amount of alloy and creates solid oxide impurities, or dross, that contaminate the melt.

The Hidden Danger of Water Vapor

Water vapor (H₂O) present in the air is an equally significant threat. At high temperatures, it provides another source of oxygen for oxidation. Furthermore, the reaction can introduce hydrogen into the molten magnesium, which can lead to porosity and voids in the final solidified casting, severely degrading its mechanical properties.

Preparing for the Protective Atmosphere

The high vacuum is not the final operating environment. Its purpose is to create a clean slate before backfilling the furnace with a high-purity inert gas, such as argon. By first removing virtually all the air, you ensure that the protective argon atmosphere (e.g., at 150 Pa) is not contaminated, providing a truly stable and inert shield for the melt.

Understanding the Consequences of an Insufficient Vacuum

Skipping or improperly performing this step has direct and severe consequences on the process and the product. A lower-quality vacuum simply isn't sufficient for a metal this reactive.

Why a "Low" Vacuum Fails

A "low" vacuum (a higher pressure) would leave behind a significant partial pressure of oxygen and water vapor. For a less reactive metal, this might be acceptable. For magnesium, even these trace amounts are enough to cause continuous, damaging oxidation throughout the heating and melting process.

The Impact on Material Quality

An inadequate vacuum leads directly to the formation of oxide inclusions within the alloy. These non-metallic particles act as stress concentration points, creating weak spots that can lead to premature cracks and component failure under load.

The Consequence of Process Unpredictability

Without a consistent, high-vacuum starting point, every melt cycle would be different. The amount of oxidative loss would vary, the level of contamination would be unpredictable, and the final chemical composition of the alloy would be inconsistent. This lack of control makes a reliable manufacturing process impossible.

Making the Right Choice for Your Goal

The level of vacuum is directly tied to the desired outcome of your metallurgical process. Understanding this link ensures you prioritize the right steps.

- If your primary focus is maximizing material yield: The high vacuum is your most effective tool for preventing the direct loss of magnesium to burn-off.

- If your primary focus is achieving superior mechanical properties: Eliminating the source of oxide inclusions and hydrogen porosity is essential for ensuring the final product's strength and integrity.

- If your primary focus is process repeatability and control: A consistent high-vacuum evacuation eliminates the variable of atmospheric contamination, making your results predictable and reliable.

Ultimately, achieving a high vacuum is the foundational act of quality control when melting highly reactive metals like AM60 magnesium alloy.

Summary Table:

| Factor | Role of High Vacuum (10⁻³ Pa) | Consequence of Insufficient Vacuum |

|---|---|---|

| Oxygen (O₂) | Removes primary oxidizer | Severe oxidative loss (burn-off), MgO dross formation |

| Water Vapor (H₂O) | Eliminates source of oxygen & hydrogen | Hydrogen-induced porosity, weakened mechanical properties |

| Process Control | Creates a clean slate for inert gas | Unpredictable melt quality, inconsistent results |

| Final Product | Ensures purity and integrity | Oxide inclusions, cracking, component failure |

Achieve flawless melts of reactive alloys like AM60 magnesium with KINTEK's precision vacuum furnace solutions.

Our Muffle, Tube, Rotary, and Vacuum furnaces are engineered with expert R&D to deliver the critical high-vacuum environment your process demands. We provide customizable systems to ensure your specific metallurgical goals for material yield, mechanical properties, and repeatable quality are met consistently.

Ready to eliminate oxidation and ensure predictable, high-quality results? Contact KINTEK today to discuss your application and let our experts help you select the ideal furnace for your needs.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys