During the heating phase of a vacuum furnace, a controlled process unfolds after the initial air has been removed. Heating elements, typically made of graphite or refractory metals, transfer energy to the workpiece almost entirely through thermal radiation. As the temperature rises, the workpiece and internal furnace components release trapped gases in a phenomenon known as outgassing, which the vacuum pumps must continuously remove to maintain the desired low-pressure environment.

The core purpose of vacuum furnace heating is not simply to make something hot. It is to achieve precise, uniform temperatures in an inert environment, using thermal radiation as the primary mechanism while actively managing the gases released by the materials themselves.

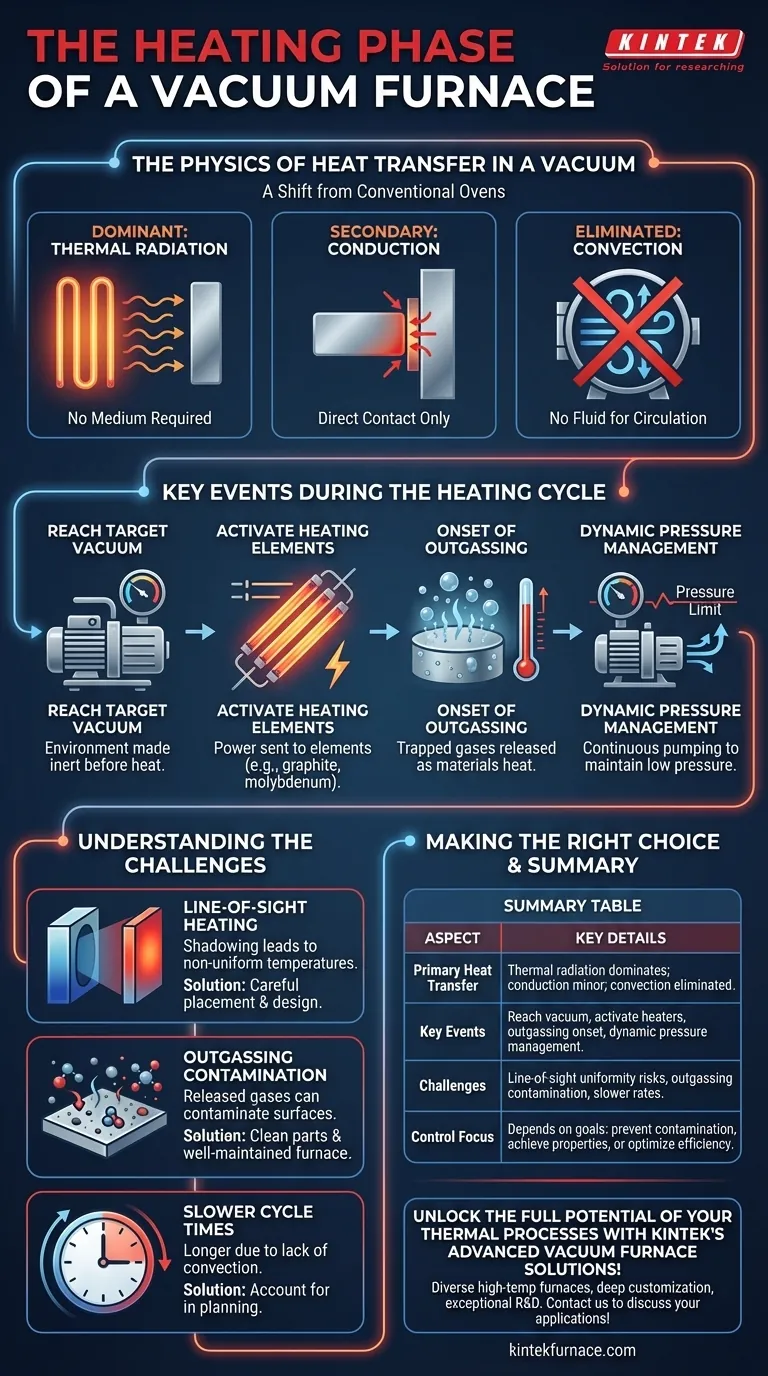

The Physics of Heating in a Vacuum

Understanding the heating phase requires a shift in thinking away from conventional ovens. With no air present, the familiar mechanism of convection is entirely absent, fundamentally changing how heat moves.

The Dominance of Thermal Radiation

In a vacuum, heat transfer occurs primarily through thermal radiation. The heating elements glow hot and emit infrared energy, which travels in a straight line through the vacuum and is absorbed by the surface of the workpiece.

This is analogous to how the sun heats the Earth across the vacuum of space. There is no medium required for the energy to travel.

The Role of Conduction

Conduction still plays a secondary role. Heat is conducted where the workpiece makes direct physical contact with fixtures, or where different parts of a complex assembly touch one another.

However, its overall contribution is much smaller than that of radiation, especially for parts with complex shapes that have minimal contact with their supports.

Why Convection is Eliminated

Convection relies on a fluid (like air or water) to circulate and transfer heat. By pumping the air out to create a vacuum, we remove the molecules needed for this process.

This is a key advantage of vacuum furnaces, as it prevents oxidation and other chemical reactions that would occur if the hot workpiece were exposed to air.

Key Events During the Heating Cycle

The heating phase is a dynamic, carefully managed sequence of events, not a static state.

Reaching the Target Vacuum

The process begins only after the vacuum pumps have evacuated the chamber to the required starting pressure, measured in Torr or mbar. This ensures the environment is inert before high temperatures are introduced.

Activating the Heating Elements

Once the vacuum is stable, power is sent to the heating elements. These are often graphite tubes or molybdenum strips that heat up due to electrical resistance. In some "hot wall" designs, the heaters are outside the sealed retort, heating the wall which then radiates energy to the parts inside.

The Onset of Outgassing

This is one of the most critical events. As the workpiece, fixtures, and even the furnace's internal insulation get hot, they release adsorbed gases and moisture from their surfaces. This process is called outgassing.

Dynamic Pressure Management

Outgassing causes the vacuum level inside the furnace to temporarily worsen. The vacuum pumping system must work continuously to remove these newly released gas molecules, ensuring the pressure does not rise above the specified limit for the process. In some cases, a controlled amount of inert gas like argon may be introduced to establish a specific partial pressure.

Understanding the Trade-offs and Challenges

While powerful, vacuum heating is not without its unique challenges that must be managed for successful processing.

The Challenge of "Line-of-Sight" Heating

Because radiation travels in straight lines, any part of the workpiece that is "shadowed" by another part or by a fixture will not heat as quickly. This can lead to non-uniform temperatures across the load.

Careful placement of parts and thoughtful furnace design are critical to ensure all surfaces receive adequate radiant energy for a uniform heat-up.

The Risk of Contamination from Outgassing

If the outgassing rate is higher than the pumping system's capacity, the pressure will rise significantly. These released gases can potentially contaminate the surface of the workpiece, defeating one of the primary purposes of using a vacuum.

This is why clean parts and a well-maintained furnace are essential for high-quality results.

Slower Heating and Cooling Rates

Without the aid of convection to circulate heat, overall cycle times in a vacuum can be longer compared to an atmosphere furnace. This must be accounted for in process planning and scheduling.

Making the Right Choice for Your Process

Controlling the heating phase is fundamental to achieving the desired metallurgical properties in your parts. The focus of that control depends on your ultimate goal.

- If your primary focus is preventing surface contamination: Your priority must be managing outgassing by ensuring parts are clean and the vacuum system can maintain the target pressure throughout the entire heating cycle.

- If your primary focus is achieving specific material properties: Precise control over the heating rate, soak temperature, and temperature uniformity across the part is your most critical set of variables.

- If your primary focus is process efficiency: You must optimize the loading configuration to minimize radiation shadowing and accurately budget for the inherently slower heat transfer rates in a vacuum environment.

Mastering the dynamics of radiative heat transfer and outgassing is the key to unlocking the full potential of vacuum thermal processing.

Summary Table:

| Aspect | Key Details |

|---|---|

| Primary Heat Transfer | Thermal radiation dominates; conduction plays a minor role; convection is eliminated. |

| Key Events | Reaching target vacuum, activating heating elements, onset of outgassing, dynamic pressure management. |

| Challenges | Line-of-sight heating risks non-uniformity, contamination from outgassing, slower heating/cooling rates. |

| Control Focus | Depends on goals: prevent contamination, achieve material properties, or optimize efficiency. |

Unlock the full potential of your thermal processes with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision