Laboratory vacuum furnaces are vital for scientific research because they create an exceptionally pure and precisely controlled environment for high-temperature processing. By removing reactive gases like oxygen, these furnaces prevent contamination and unwanted chemical reactions. This allows scientists to isolate variables and study the intrinsic properties of materials with a level of accuracy and repeatability that is otherwise impossible to achieve.

The core value of a laboratory vacuum furnace is not just heating—it's control. By eliminating the unpredictable influence of the atmosphere, researchers can ensure that the observed changes in a material are a direct result of the applied thermal process, making their findings fundamentally more reliable.

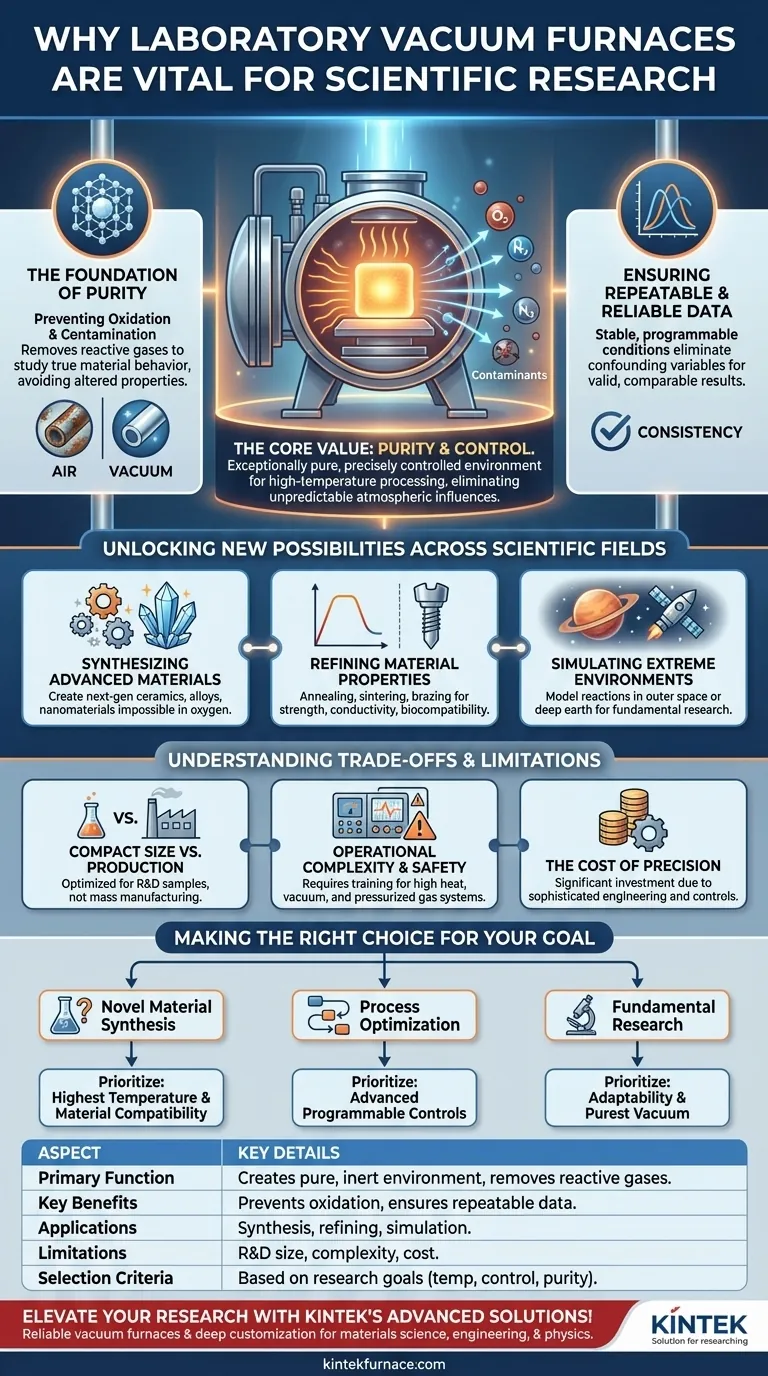

The Foundation of Purity: Eliminating Unwanted Variables

The primary function of a vacuum is to create a clean, inert environment. This seemingly simple feature is the key to unlocking advanced scientific insights.

Preventing Oxidation and Contamination

At high temperatures, most materials readily react with oxygen and other atmospheric gases. This oxidation and contamination can completely alter a material's structural and chemical properties.

A vacuum furnace removes these reactive gases, creating an oxygen-free environment. This ensures that the material being tested remains in its pure form, allowing researchers to study its true behavior under heat.

Ensuring Repeatable and Reliable Data

The scientific method depends on repeatability. Experiments must yield the same results under the same conditions to be considered valid.

Because vacuum furnaces offer precise, programmable control over both temperature and atmosphere, they create a stable and reproducible experimental environment. This consistency eliminates confounding variables and ensures that data gathered today can be reliably compared to data gathered tomorrow.

Unlocking New Possibilities Across Scientific Fields

By providing this controlled environment, laboratory vacuum furnaces are indispensable tools for innovation in materials science, engineering, and physics.

Synthesizing Advanced Materials

Many next-generation materials, such as high-performance ceramics, advanced metal alloys, and nanomaterials, cannot be created in the presence of oxygen.

Vacuum furnaces provide the necessary inert atmosphere for synthesizing these materials, studying their phase transformations, and understanding how their microstructures evolve at high temperatures.

Refining Material Properties

Processes like annealing, sintering, and brazing are used to improve the properties of a material, such as its strength, conductivity, or biocompatibility.

In semiconductor research, annealing in a vacuum repairs crystal lattice damage. In biomedical engineering, sintering is used to densify ceramic medical implants, making them strong enough for use in the human body. These processes demand the purity only a vacuum can provide.

Simulating Extreme Environments

Vacuum furnaces enable scientists to simulate conditions that are difficult to create otherwise. They are used to model the reactions materials undergo in outer space or deep within the earth's crust.

This capability is critical for fundamental research in physics, chemistry, and planetary science, including the synthesis and study of novel quantum materials.

Understanding the Trade-offs and Limitations

While powerful, laboratory vacuum furnaces are specialized instruments with specific considerations. Understanding their limitations is key to using them effectively.

Compact Size vs. Production Scale

Laboratory models are specifically designed for research and development. Their chambers are relatively small, optimized for testing samples, not for mass production. Industrial-scale furnaces are required to transition a successful lab process to manufacturing.

Operational Complexity and Safety

Operating a high-temperature vacuum system is more complex than using a standard oven. It requires training to manage vacuum pumps, monitor pressure levels, and handle inert gas backfilling. Safety protocols are critical, as these systems combine high heat, high vacuum, and pressurized gas.

The Cost of Precision

The high degree of control offered by laboratory vacuum furnaces comes from sophisticated programmable logic controllers (PLCs), high-quality heating elements, and robust vacuum systems. This level of engineering makes them a significant investment compared to atmospheric furnaces.

Making the Right Choice for Your Research Goal

Selecting a vacuum furnace depends entirely on the scientific question you aim to answer. Your primary goal will dictate the most important features.

- If your primary focus is novel material synthesis: Choose a furnace with the highest possible temperature range and compatibility with different heating elements (e.g., molybdenum, tungsten, or graphite) to handle a wide variety of materials.

- If your primary focus is process optimization (like annealing): Prioritize a furnace with advanced programmable controls that allow for precise, multi-stage thermal ramps, soaks, and controlled cooling cycles.

- If your primary focus is fundamental research: Look for an adaptable system that can integrate with analytical tools and provides the purest possible vacuum to isolate experimental variables completely.

Ultimately, a laboratory vacuum furnace is an investment in certainty, giving researchers the power to control their experimental world and produce unambiguous results.

Summary Table:

| Aspect | Key Details |

|---|---|

| Primary Function | Creates a pure, inert environment by removing reactive gases like oxygen. |

| Key Benefits | Prevents oxidation and contamination; ensures repeatable, reliable data. |

| Applications | Synthesizing ceramics, alloys, nanomaterials; annealing, sintering, brazing; simulating extreme environments. |

| Limitations | Compact size for R&D; operational complexity; higher cost due to precision controls. |

| Selection Criteria | Based on research goals: high temperature for synthesis, programmable controls for process optimization, adaptability for fundamental studies. |

Elevate your research with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere models, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering purity, control, and repeatability for materials science, engineering, and physics applications. Contact us today to discuss how we can support your groundbreaking work!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity