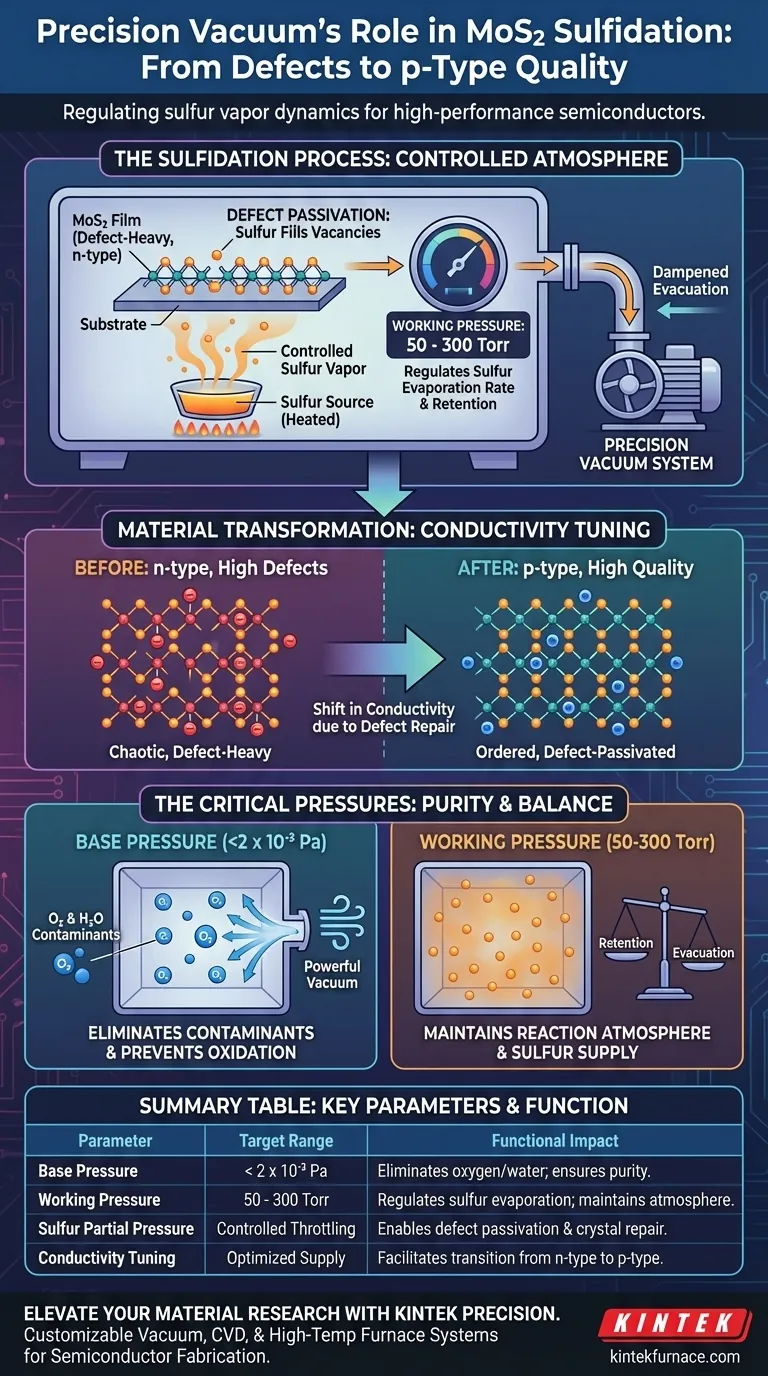

A precision vacuum system acts as the primary regulator of sulfur vapor dynamics during the sulfidation process. It controls the working pressure within the chamber, specifically targeting a range between 50 and 300 Torr, to balance the evaporation rate of sulfur powder. By maintaining this pressure, the system prevents the rapid loss of sulfur, ensuring a sufficient supply is available to chemically interact with the Molybdenum Disulfide (MoS2) film.

By throttling the evaporation of sulfur, the vacuum system creates the exact thermodynamic conditions required to repair atomic defects. This control is the deciding factor in transforming MoS2 from a defect-heavy n-type material into a high-quality p-type semiconductor.

The Mechanics of Pressure Regulation

Controlling Sulfur Partial Pressure

The core function of the vacuum system during sulfidation is to regulate the partial pressure of sulfur vapor.

Rather than creating a void, the system maintains a specific working pressure—typically between 50 and 300 Torr. This pressure range is carefully calculated to sustain the reaction environment.

Managing Evaporation Rates

If the chamber pressure drops too low, sulfur powder evaporates too quickly and is evacuated from the system.

The vacuum system acts as a dampener, keeping the pressure high enough to suppress excessive evaporation. This ensures the sulfur remains in the chamber long enough to act as a source for the reaction.

Impact on Material Properties

Facilitating Defect Passivation

The primary goal of retaining sulfur vapor is to achieve "defect passivation."

MoS2 films often contain atomic vacancies or defects. An adequate, pressurized sulfur atmosphere allows sulfur atoms to fill these gaps, effectively repairing the crystal structure.

Tuning Conductivity Types

The most significant outcome of this pressure regulation is a shift in electrical conductivity.

Unregulated films often exhibit n-type conductivity characterized by high defect density. By ensuring sufficient sulfur presence for passivation, the vacuum system enables the transformation of the film into high-quality p-type conductivity with significantly fewer defects.

The Role of Base Pressure

Eliminating Contaminants

While working pressure controls sulfur, the "base pressure" sets the stage for purity.

Before the process begins, the vacuum system must achieve a high vacuum state, often as low as 2 x 10^-3 Pa. This step is distinct from the sulfidation pressure regulation but is equally critical.

Preventing Oxidation

Achieving this low base pressure removes residual oxygen and water vapor from the chamber.

This prevents the Molybdenum Disulfide from oxidizing during heating or deposition. Eliminating these contaminants ensures the correct stoichiometry and preserves the purity of the semiconductor characteristics.

Understanding the Trade-offs

The Balance of Retention vs. Evacuation

There is a delicate balance between retaining sulfur and maintaining a dynamic flow.

If the pressure is too high, the process may become stagnant; if it is too low, the sulfur source is depleted before passivation is complete. The system must actively monitor this to stay within the 50–300 Torr window.

Sensitivity to Contamination

Reliance on a vacuum environment makes the process highly sensitive to leak rates.

Even minor leaks that compromise the base pressure (2 x 10^-3 Pa) can introduce oxygen, negating the benefits of the subsequent sulfur passivation. A robust vacuum seal is a non-negotiable requirement for high-performance MoS2.

Making the Right Choice for Your Goal

To optimize your MoS2 thin film production, you must configure your vacuum system based on the specific phase of the process.

- If your primary focus is Film Purity and Stoichiometry: Prioritize achieving a base pressure of 2 x 10^-3 Pa or lower to eliminate oxygen and water vapor before the process begins.

- If your primary focus is Conductivity Tuning (n-type to p-type): Focus on precise downstream pressure control to maintain the chamber between 50 and 300 Torr, ensuring maximum sulfur availability for defect repair.

The vacuum system is not merely a pump; it is the active controller of the chemical potential that defines the final quality of your semiconductor.

Summary Table:

| Parameter | Target Range | Functional Impact on MoS2 |

|---|---|---|

| Base Pressure | < 2 x 10^-3 Pa | Eliminates oxygen/water; prevents oxidation and ensures purity. |

| Working Pressure | 50 - 300 Torr | Regulates sulfur evaporation rate; maintains reaction atmosphere. |

| Sulfur Partial Pressure | Controlled Throttling | Enables defect passivation and crystal structure repair. |

| Conductivity Tuning | Optimized Supply | Facilitates transition from defect-heavy n-type to high-quality p-type. |

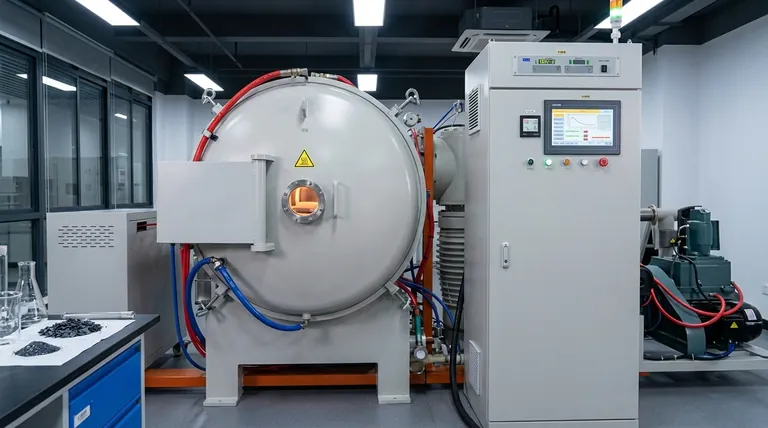

Elevate Your Material Research with KINTEK Precision

Achieving the delicate balance of sulfur partial pressure and high-vacuum purity requires equipment engineered for excellence. KINTEK provides industry-leading Vacuum, CVD, and high-temperature furnace systems specifically designed to meet the rigorous demands of semiconductor fabrication.

Backed by our expert R&D and advanced manufacturing, our customizable solutions ensure your MoS2 sulfidation processes achieve perfect stoichiometry and defect passivation every time.

Ready to optimize your thin-film production?

Contact KINTEK Experts Today to discuss your unique laboratory requirements and discover the precision of our customizable thermal systems.

Visual Guide

References

- Md Shariful Islam, Nowshad Amin. Pressure-dependent sulfurization of molybdenum thin films for high-quality MoS<sub>2</sub> formation. DOI: 10.1088/1755-1315/1500/1/012020

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are some examples of vacuum brazing projects? Discover High-Strength Joining for Aerospace and Medical

- How does temperature control precision of industrial melting furnaces affect intermetallic phase selection?

- Why is a precision vacuum drying oven required for processing electrode sheets in LMFP slurry coating? Essential Drying

- What role does a vacuum annealing furnace play in evaluating Ag2S1-xTex phase stability? Map Material Limits Precisely

- Why is a high-temperature homogenization furnace treatment necessary for (CoCrNi)94Al3Ti3 alloys? Ensure Metal Purity

- How does a vacuum arc furnace operate? Achieve Ultra-Pure Metals for Demanding Applications

- What safety features are integrated into vacuum pressure sintering furnaces? Ensure Operator and Equipment Protection

- What is the primary function of a laboratory vacuum drying oven? Essential Electrode Sheet Processing Explained