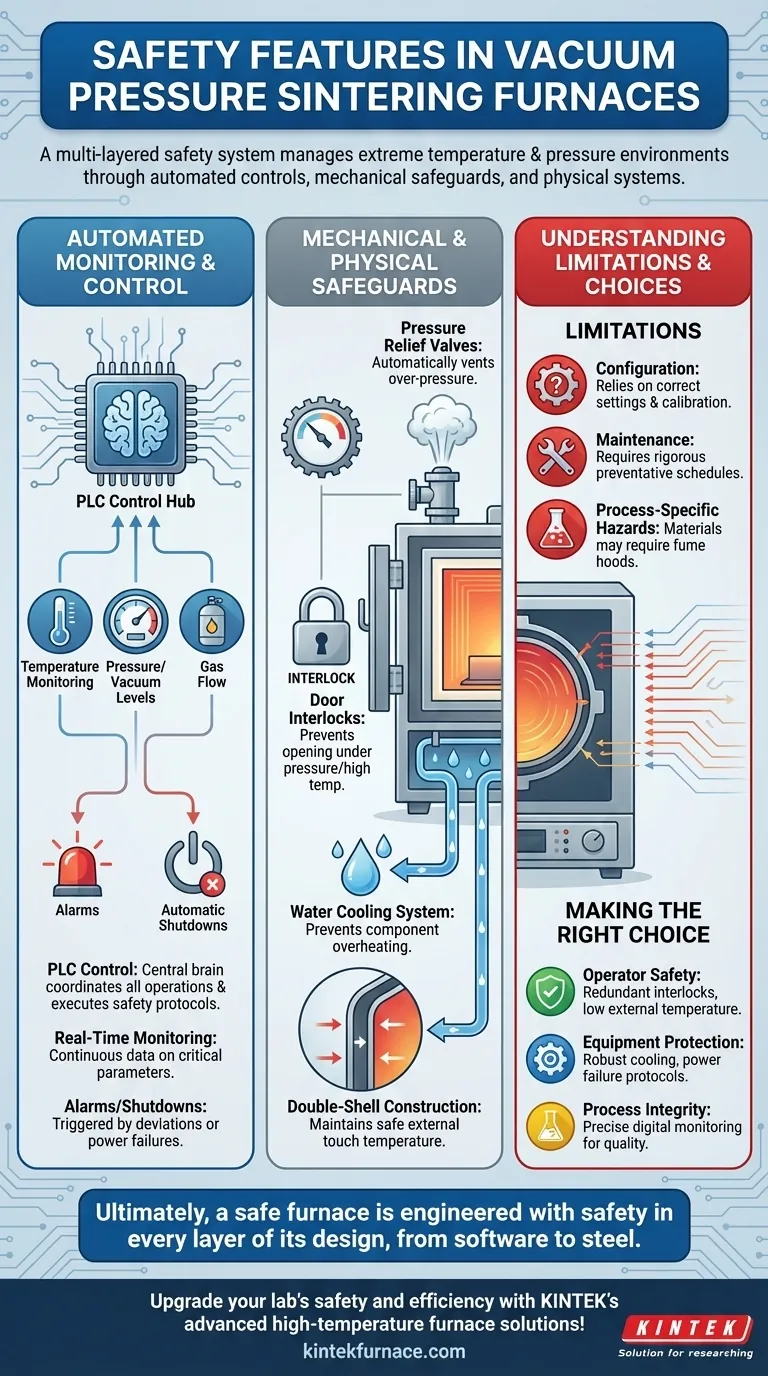

At its core, a vacuum pressure sintering furnace integrates a multi-layered safety system to manage its extreme temperature and pressure environments. The primary features include automated process monitoring via a central PLC, mechanical safeguards like door interlocks and pressure relief valves, and robust physical systems such as water cooling to prevent equipment failure and ensure operator safety.

Safety in these advanced furnaces is not a single feature, but an integrated design philosophy. It combines the intrinsic safety of a vacuum environment with redundant software controls and robust mechanical engineering to protect the operator, the equipment, and the final product.

The Foundation: Automated Monitoring and Control

The "brain" of the furnace's safety system is its Programmable Logic Controller (PLC). This centralized computer coordinates all operations and acts as the first line of defense against anomalies.

PLC Control and Protection System

A comprehensive PLC system is the central hub for all safety functions. It receives data from sensors throughout the furnace and can execute pre-programmed safety protocols without human intervention.

This automated control ensures that critical parameters remain within safe operating limits throughout the entire sintering cycle.

Real-Time Parameter Monitoring

The PLC continuously monitors key operational data. This includes temperature, pressure/vacuum levels, and gas flow.

If any of these parameters deviate from the setpoint, the system can immediately trigger an alarm or initiate a controlled shutdown sequence.

Alarms and Automatic Shutdowns

Standard safety protocols include over-temperature alarms and power failure protection.

In the event of an abnormality, such as a sudden temperature spike or a loss of facility power, the system is designed to automatically and safely shut down the equipment, preserving both the furnace and the workload inside.

Mechanical and Physical Safeguards

Beyond software, the furnace's physical design incorporates multiple mechanical features to guarantee safety, especially during direct interaction by an operator.

Door Interlocks and Locking Mechanisms

Furnace doors are equipped with automatic locking mechanisms and safety interlocks. These features physically prevent the door from being opened when the chamber is pressurized, under vacuum, or at a high temperature.

This is a critical safeguard that protects operators from exposure to hazardous conditions.

Pressure and Vacuum Integrity

The furnace chamber is a sealed vessel designed to maintain vacuum integrity. To protect against over-pressurization, emergency pressure release valves are installed.

These mechanical valves automatically vent the chamber if the internal pressure exceeds a safe threshold, preventing catastrophic failure of the vessel.

Advanced Cooling Systems

An internal circulation pure water cooling system is essential. It prevents the furnace shell and critical components from overheating during operation at temperatures that can exceed 2000°C.

Effective cooling is crucial not only for equipment longevity but also for keeping the furnace's external surfaces at a safe temperature for personnel.

Insulated Construction

Many modern furnaces use a double-shell construction. This design allows for a cooling medium (like water) to circulate between the inner and outer shells, keeping the external case temperature low and safe to the touch.

Understanding the Inherent Limitations

While these systems are robust, it is critical to recognize that they are not infallible. Understanding their limitations is key to maintaining a truly safe operating environment.

Automation Relies on Correct Configuration

An automated safety system is only as good as its programming and its sensors. Incorrectly set parameters or a malfunctioning sensor can compromise the entire safety network. Regular calibration and human oversight remain essential.

Maintenance is Non-Negotiable

Safety components like pressure relief valves, seals, and cooling system pumps are subject to wear. A rigorous preventative maintenance schedule is not optional; it is a fundamental requirement for ensuring these features will function when needed.

Process-Specific Hazards

The material being sintered can introduce unique risks. Some materials may produce volatile compounds or off-gas during heating, which may require specialized fume hoods or local exhaust systems to ensure air quality and prevent hazardous buildup.

Making the Right Choice for Your Goal

Evaluating a furnace's safety features should be directly tied to your primary operational priorities.

- If your primary focus is operator safety: Look for redundant door interlocks, low external surface temperatures via double-shell cooling, and clear, unambiguous PLC alarm notifications.

- If your primary focus is equipment protection: Prioritize a robust water cooling system, comprehensive power failure protection, and reliable over-temperature and over-pressure shutdown protocols.

- If your primary focus is process integrity: Ensure the furnace offers precise, digitally controlled monitoring of temperature, vacuum levels, and gas flow to guarantee quality and repeatability.

Ultimately, a safe furnace is one where safety is engineered into every layer of its design, from the software to the steel.

Summary Table:

| Safety Feature | Key Components | Primary Function |

|---|---|---|

| Automated Monitoring | PLC, Sensors | Monitors temperature, pressure, gas flow; triggers alarms and shutdowns |

| Mechanical Safeguards | Door Interlocks, Pressure Relief Valves | Prevents door opening under hazardous conditions; vents over-pressure |

| Physical Systems | Water Cooling, Double-Shell Construction | Prevents overheating; maintains safe external temperatures |

| Process Controls | Alarms, Automatic Shutdowns | Ensures safe shutdown during anomalies like power failure or over-temperature |

Upgrade your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing operator protection and process integrity. Contact us today to discuss how we can support your goals with tailored, safe furnace technology!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability

- What materials are used for the tubes in a High Temperature Tube Furnace? Choose the Right Tube for Your Lab

- Why is a high-precision vacuum tube furnace essential for CVD graphene? Master Growth Control & Purity

- How to clean a tube furnace? A Step-by-Step Guide to Safe and Effective Maintenance